Primer-topcoat paint for automobile parts and preparation method thereof

A technology for auto parts and bottom surfaces, applied in the field of coatings, can solve the problems of inconvenient use, salt spray resistance, pollution resistance, impact resistance, and unsatisfactory flexibility, and achieve excellent moisture resistance, excellent adhesion, good The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

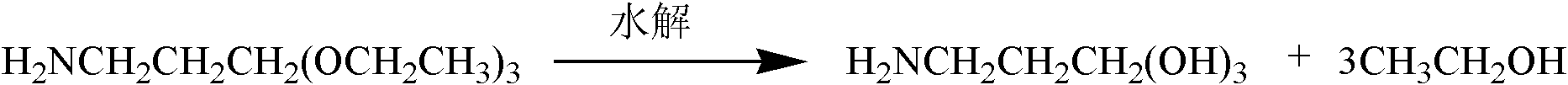

Method used

Image

Examples

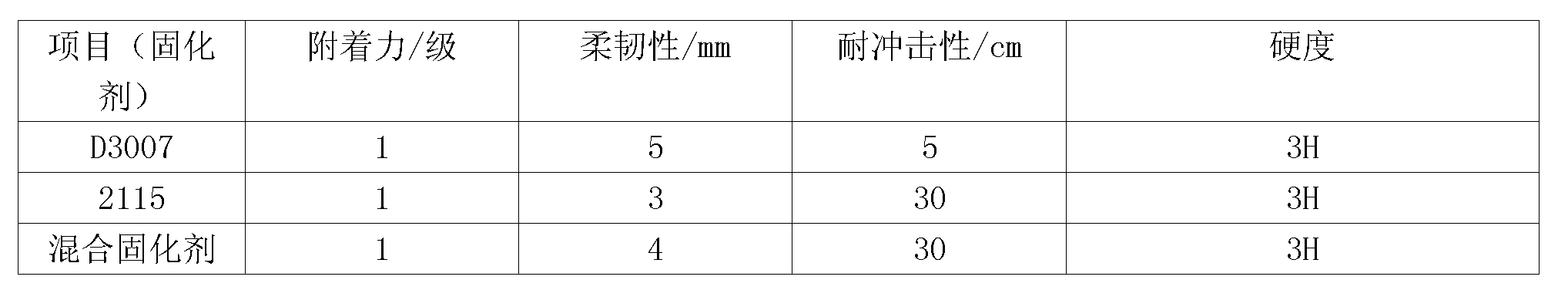

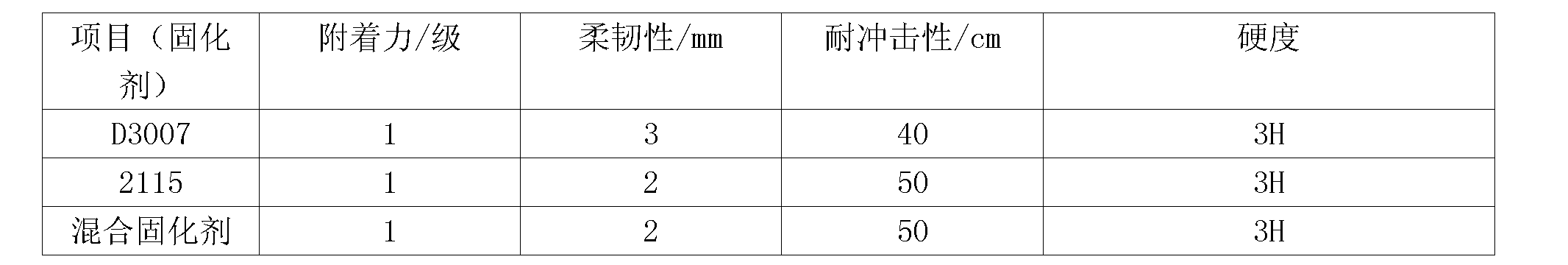

Embodiment 1

[0038] A kind of bottom and surface all-in-one auto parts paint, which is composed of component A of paint main agent and component B of curing agent. In terms of content, the mass percent of each component in the paint main agent is:

[0039] Epoxy resin 634-80 32%;

[0040] Epoxy resin 601-75 16%;

[0041] 582 resin 1.5%;

[0042] Dispersant 1.0%;

[0043] Carbon black 3%;

[0044] Aluminum tripolyphosphate 10%;

[0047] Talc 7%;

[0048] Defoamer 0.4%;

[0049] Leveling agent 0.4%;

[0050] Coupling agent KH550 0.5%;

[0051] Anti-sedimentation agent 1.2%;

[0052] Diacetone Alcohol 8%.

[0053] According to the content in the curing agent, the mass percentage of each component in the curing agent is:

[0054] Polyamide 2115 25%;

[0055] 3007 curing agent 45%;

[0056] Mixed solvent 30%;

[0057] The bottom-surface-integrated auto parts paint is prepared according to the following steps:

[0058] 1) Add e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com