Biodegradable cigarette fiber material and cigarette filter tip

A technology of biodegradation and fiber materials, applied in the fields of e-liquid filter elements, fiber treatment, fiber chemical characteristics, etc., can solve the problems of PBS application without records, etc., and achieve the effect of good biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

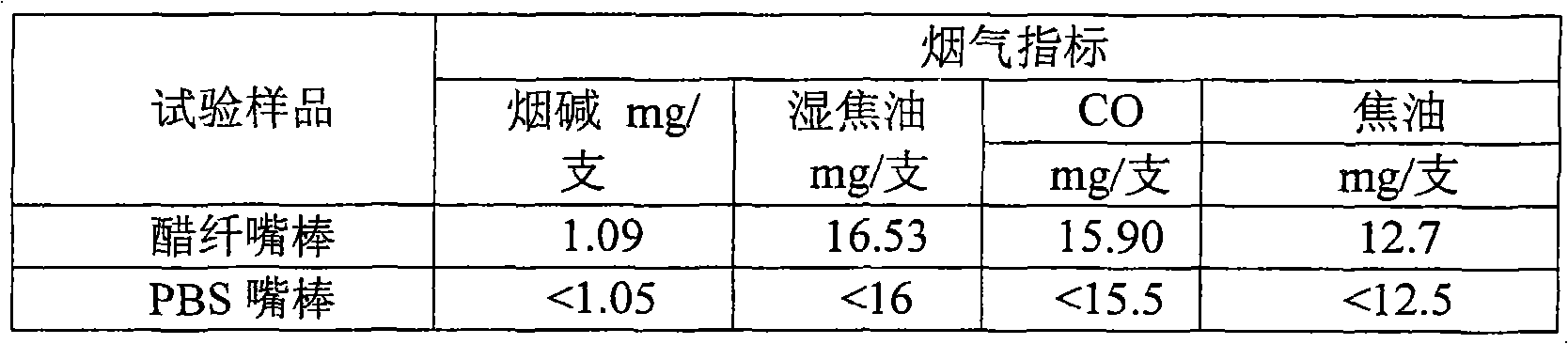

Image

Examples

Embodiment 1

[0052] Homopolybutylene succinate (PBS) with a weight-average molecular weight of 15±10,000 and a dispersion index of 1.7 was selected as the base resin. According to PBS: triphenyl phosphite: epoxidized soybean oil: amino resin, it was 97 : Weigh the material in a weight ratio of 0.5:1.5:1, dry it in an oven at about 65°C for 2 hours, stir it evenly in a high-speed mixer, and extrude it on a Φ57 twin-screw extruder with an aspect ratio of 32. The barrel temperature is set to 120°C for the first stage, 140°C for the second stage, 150°C for the third stage, 150°C for the fourth stage, and 145°C for the fifth stage. The extruded strip is cut into pellets by a pelletizer, dried with hot air online, and packaged to obtain the special material for cigarette holder sticks of the present invention.

[0053] The above-mentioned special material for cigarette holder is spun on a Φ65 melt spinning machine with a screw length-diameter ratio of 28. The temperature of the first section of ...

Embodiment 2

[0060] The weight-average molecular weight is (10±1) ten thousand, the dispersion index is 1.2, and the molecular chain contains 18% (number of chain segments) randomly distributed terephthalic acid-linked copolymerized polybutylene succinate (PBS) As the base resin, the material was weighed in a ratio of 94: 1: 5 according to the weight ratio of copolymerized PBS: trimethyl phosphate: long-chain phosphorus-sulfur compound H-MOD, dried in a 60 ℃ oven for 3 hours, Mix evenly in a high-speed mixer, extrude and granulate on a Φ65 twin-screw extruder with a length-to-diameter ratio of 28, and set the screw barrel temperature to 125°C for the first stage, 145°C for the second stage, and 155°C for the third stage. , the fourth segment is 155°C, and the fifth segment is 145°C. The extruded strip is cut into pellets by a pelletizer, dried with hot air online, and packaged to obtain the special material for cigarette holder sticks of the present invention.

[0061] The above-mentioned...

Embodiment 3

[0068] It is 350,000 to choose the weight average molecular weight, and the dispersion index is 3.0, and the copolymerized polybutylene succinate (PBS) that contains 30% (number of chain members) randomly distributed hexanediol links on its molecular chain is base resin It is the substrate resin. After drying in an oven at 60°C for 3 hours, it is spun on a Φ65 melt spinning machine with a screw length-to-diameter ratio of 28. The screw temperature of the spinning machine is set to 130°C for the first stage, and 130°C for the second stage. The second stage is 145°C, the third stage is 155°C, the filter temperature is 155°C, the box temperature is 155°C, and the straight pipe temperature is 155°C. After being sprayed out from a spinneret with a specification of 1050×3, it is cooled by side blowing of dry air with a temperature range of 20 to 40°C.

[0069] The tow after above-mentioned cooling is coated with oil agent in the oiling tank, and the oiling agent in the oiling tank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

| Draw resistance | aaaaa | aaaaa |

| Draw resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com