Lanthanum oxide-based sintered object, sputtering target comprising the sintered object, process for producing lanthanum oxide-based sintered object, and process for sputtering target production using the process

A manufacturing method and technology of lanthanum oxide, which can be used in semiconductor/solid-state device manufacturing, sputtering, semiconductor devices, etc., and can solve problems such as difficulty in providing sputtering targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

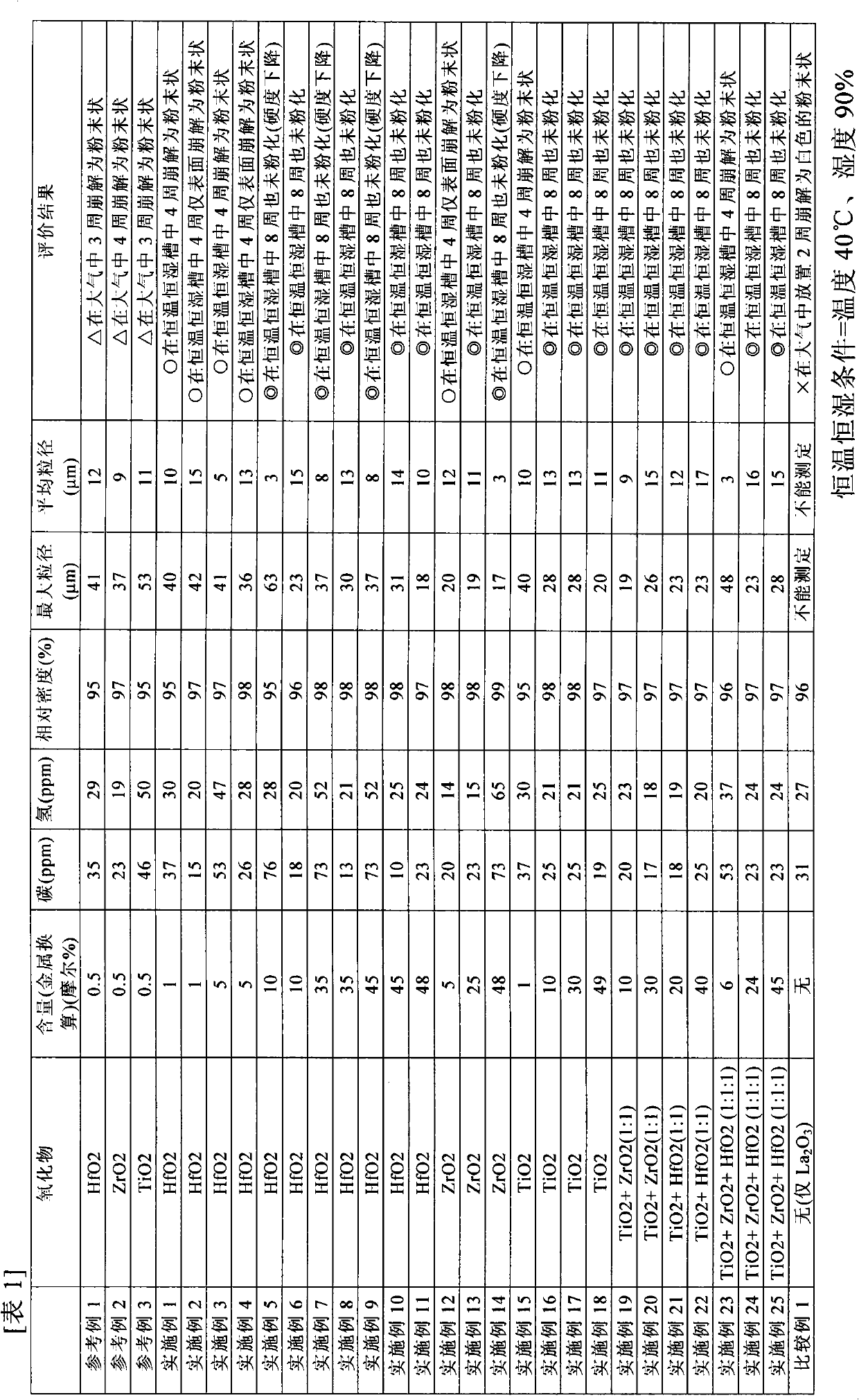

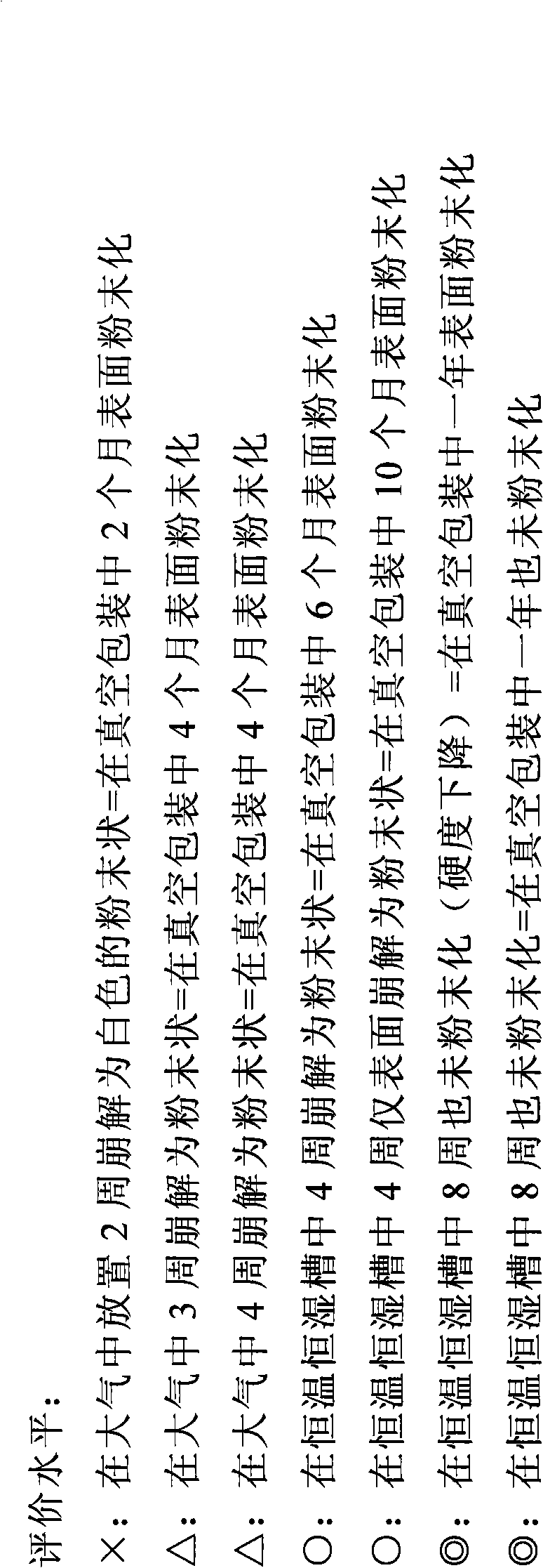

[0060] Examples are described below. In addition, this example is only for easy understanding of the present invention, and does not limit the present invention. That is, other embodiments and modifications within the scope of the technical concept of the present invention are also included in the present invention. In addition, in the following content, although the example given as a reference example is not sufficient from the objective of this application, the characteristic improvement similar to the invention of this application was observed. Regarding Comparative Example 1, it is described in lines 22 to 26 on page 22.

[0061] (reference example 1-3, embodiment 1-25)

[0062] Using La2(CO 3 ) 3 Powder and HfO 2 , ZrO 2 、TiO 2 Powder As a raw material powder, the raw material powder is blended so that the amount of Hf, Zr, and Ti is 0.5 mol % to 49 mol % with respect to the total amount of metal components including La, and mixed using a wet ball mill. This mixe...

reference example 1

[0069] The composite oxide sintered body of Reference Example 1 contained 0.5 mol% of hafnium in terms of the metal of the composite oxide sintered body (lanthanum oxide and hafnium oxide), that is, contained Hf in terms of mol% of Hf / (La+Hf). 0.5%. The same applies to other reference examples and examples below. In addition, for reference only, based on the mole % of Hf / (La+Hf), containing 50 mole % of Hf as La 2 f 2 o 7 The composition of La 2 o 3 33.3 mol%, HfO 2 It is 66.7 mol%.

[0070] The carbon content is 35 ppm, the hydrogen is 29 ppm, the relative density is 95%, the maximum particle size is 41 μm, and the average particle size is 12 μm. At this time, HfO 2 The amount is slightly less than the preferred conditions of the present invention, the carbon content is slightly more than the preferred conditions of the present invention, and the relative density is lower, being 95%. As a result, the sintered body disintegrated into a powder form after 3 weeks in the...

reference example 2

[0073] The composite oxide sintered body of Reference Example 2, in terms of metal, ZrO 2 It contains 0.5 mol% in conversion of Zr. The carbon content is 23 ppm, the hydrogen is 19 ppm, the relative density is 97%, the maximum particle diameter is 37 μm, and the average particle diameter is 9 μm. At this time, ZrO 2 The amount is slightly less than the preferred condition of the present invention, but the relative density is slightly higher, which is 97%. As a result, the sintered body disintegrated into a powder form after 4 weeks in the air. There are some improvements over Reference Example 1.

[0074] However, in vacuum packaging, no powdering of the surface was observed during 4 months. The sintered body at this level has a slightly higher disintegration speed, but it can be said to be in the range of practical application level if vacuum packaging is used. The evaluation was Δ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com