Preparation method of quaternary degradable antibacterial agent

A kind of antibacterial agent, quaternization technology, applied in the field of preparation of degradable polyester antibacterial agent, can solve the problems such as difficult to remove, poor biocompatibility, etc., achieve good antibacterial performance, good stability and biocompatibility, and prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] 1) Synthesis of 2,2-dibromomethyltrimethylene carbonate monomer (DBTC)

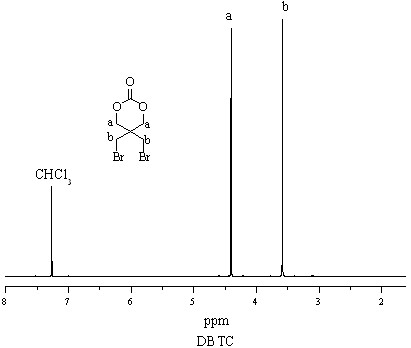

[0020] 7.0 g (0.03 mol) of dibromoneopentyl glycol and 5.7 mL (0.06 mol) of ethyl chloroformate were added to a round bottom flask containing 200 mL of THF at a ratio of 1:2, and the mixture was stirred at 0 °C for 30 min. And drop 8.3mL (0.06 mol) of triethylamine (TEA) into the round-bottomed flask, stir overnight at room temperature, filter off the TEA·HCl precipitate, concentrate the filtrate under reduced pressure and then precipitate with ether to obtain 2, 2-Dibromomethyltrimethylene carbonate monomer, its H NMR spectrum is shown in Figure 1.

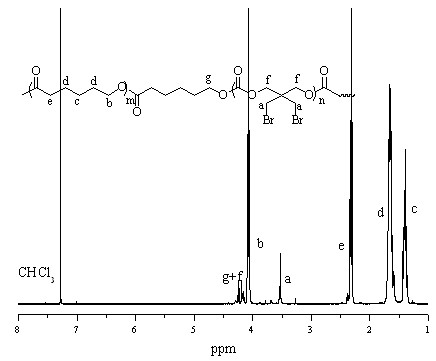

[0021] 2) Polymerization of DBTC and caprolactone (poly(DBTC- co -CL)).

[0022] In the polymerization bottle, add 2,2-dibromomethyltrimethylene carbonate monomer and caprolactone in different feeding ratios, and press 2,2-dibromomethyltrimethylene carbonate monomer under the protection of argon The molar ratio of the sum of the moles of caprolact...

example 2

[0031] 1) Monomer is synthesized with example 1

[0032]2) Synthesis of 2,2-dibromomethyltrimethylene carbonate (DBTC) homopolymer (PDBTC)

[0033] Add 0.2 g (0.69 mmol) 2,2-dibromomethyltrimethylene carbonate monomer to the polymerization bottle, and add 0.7 mg catalyst Sn( Oct) 2 , sealed under argon protection, and polymerized at 110 °C for 12 h. The product was eluted with a little THF and precipitated with ether.

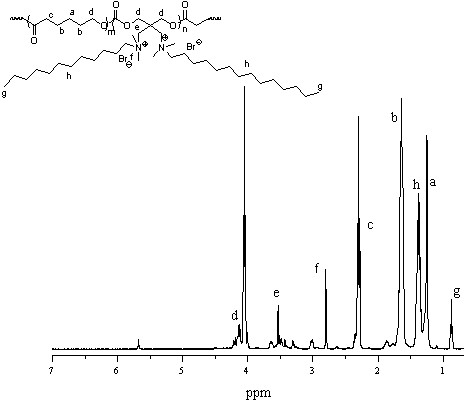

[0034] 3) Synthesis of quaternized degradable antimicrobial agent based on PDBTC

[0035] PDBTC was added into a 100 mL round-bottomed flask according to the molar ratio of Br functional group to alkyl tertiary amine 1:2, and then KBr with twice the molar number of bromine functional groups was added as a catalyst, and DMF was used as a solvent to react at 80 °C for 120 h, namely Get the product.

example 3

[0037] 1) Monomer is synthesized with example 1

[0038] 2) 2,2-Dibromomethyltrimethylene carbonate (DBTC) and monomethoxypolyethylene with a molecular weight of 1000

[0039] Diol (mPEG 1000 -OH) copolymerization (mPEG 1000 -co-PDBTC).

[0040] In the polymerization bottle, add 2,2-dibromomethyltrimethylene carbonate monomer and mPEG in a mass ratio of 1:1 1000 -OH, by 2,2-dibromomethyltrimethylene carbonate monomer and mPEG under argon 1000 The molar ratio of the molar sum of -OH to the catalyst is 400:1 and the catalyst Sn(Oct) is added 2 , sealed under the protection of argon, and polymerized at 110 ℃ for 12 h. The product was eluted with THF and precipitated with ether.

[0041] 3) with mPEG 1000 Synthesis of quaternized degradable antibacterial agent with -co-PDBTC as the backbone

[0042] mPEG 1000 -co-PDBTC was added to a 100 mL round-bottomed flask at a molar ratio of Br functional group to alkyl tertiary amine of 1:2, and then KBr with twice the molar nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com