High comparative tracking index value flame-retardant and reinforced polybutylene terephthalate material and preparation method and application thereof

A polybutylene terephthalate, flame retardant technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of high price, poor mechanical properties, harsh injection molding conditions, etc. CTI value, reduced formation, reduced free radical generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

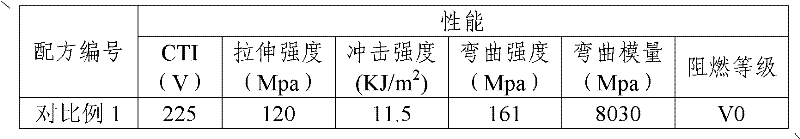

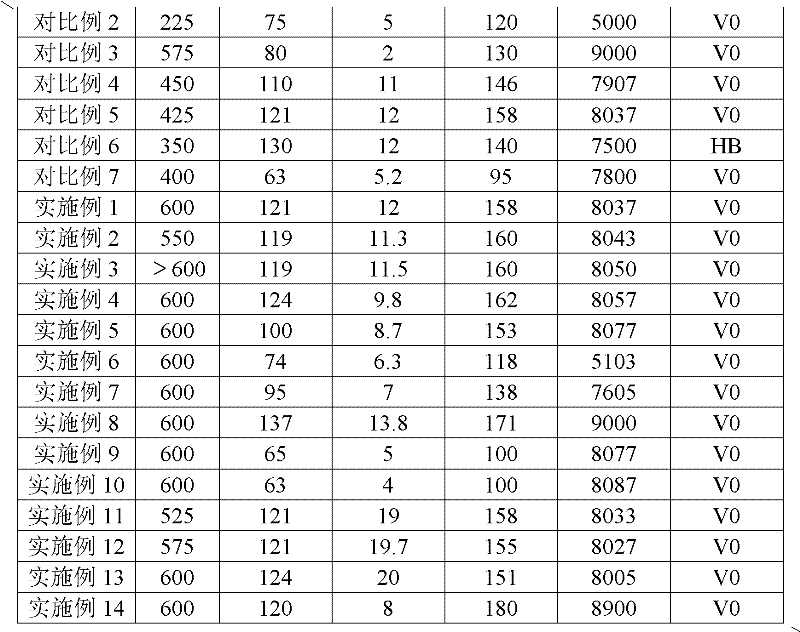

Examples

Embodiment 1

[0064] (1) 1860g PBT (produced by Jiangsu Yizheng Chemical Industry), 320g brominated styrene (BPS) (Japan Daiichi Industrial Pharmaceutical Co.), 200g antimony trioxide (Beijing Xingbeida Trading Company), 80g talcum powder (Foshan Chengji) Chemical Trading Company), 200g PTW (DuPont, USA), 120g CTI synergist (sodium metaborate and titanium dioxide with a particle size of 30-100nm are mixed in a mass ratio of 1:1, the same below), 4g antioxidant 1076 (BASF Company), 4g antioxidant 168 (Basf Corporation) and 12g ethylene bis stearic acid amide (EBS) are mixed 3min in high-speed mixer at 800rpm with rotating speed, obtain the compound that mixes;

[0065] (2) Add the compound obtained in step (1) from the main feeding port of the twin-screw extruder (diameter is 35mm, aspect ratio 40), and 1200g chopped glass fibers (alkali-free, Chongqing International Composite Material Co., Ltd.) from the twin-screw extruder The second feeding port of the screw extruder is added, mixed evenl...

Embodiment 2

[0068] (1) 1740g PBT (produced by Jiangsu Yizheng Chemical Co., Ltd.), 400g brominated styrene (BPS) (Japan Daiichi Industrial Pharmaceutical Company), 160g antimony trioxide (Beijing Xingbeida Trading Company), 80g talcum powder (Foshan Chengji) Chemical Trading Company), 200g MBS (Dow Company), 200g CTI synergist, 4g antioxidant 1076 (BASF), 4g antioxidant 168 (BASF) and 12g EBS are 800rpm high speed mixing 10min with rotating speed, obtain a well-mixed mixture;

[0069] (2) Add the compound obtained in step (1) from the main feeding port of the twin-screw extruder (diameter is 35mm, aspect ratio 40), and 1200g chopped glass fibers (alkali-free, Chongqing International Composite Material Co., Ltd.) from the twin-screw extruder The second feeding port of the screw extruder is added, mixed evenly in the twin-screw extruder, and then extruded and pelletized to obtain a high CTI value flame-retardant reinforced polybutylene terephthalate material. The processing conditions of t...

Embodiment 3

[0072] (1) 1620g PBT (produced by Jiangsu Yizheng Chemical Industry), 480g brominated styrene (BPS) (Japan Daiichi Industrial Pharmaceutical Co.), 120g antimony trioxide (Beijing Xingbeida Trading Company), 80g talcum powder (Foshan Chengji) Chemical Trading Company), 200g PE-MAH (Shenyang Ketong Company), 280g CTI synergist, 4g antioxidant 1076 (BASF), 4g antioxidant 168 (BASF) and 12g EBS with a rotating speed of 800rpm high-speed mixing 10min, obtain the mixture that mixes homogeneously;

[0073] (2) Add the compound obtained in step (1) from the main feeding port of the twin-screw extruder (diameter is 35mm, aspect ratio 40), and 1200g chopped glass fibers (alkali-free, Chongqing International Composite Material Co., Ltd.) from the twin-screw extruder The second feeding port of the screw extruder is added, mixed evenly in the twin-screw extruder, and then extruded and pelletized to obtain a high CTI value flame-retardant reinforced polybutylene terephthalate material. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com