Composite fungicide for rapid degradation of organic waste and applications thereof

A technology of organic waste and compound bacterial agent, which is applied in the direction of microorganism-based methods, bacteria, microorganisms, etc., can solve the problems of unbalanced culture medium nutrients, unbalanced growth of strains, easy contamination of miscellaneous bacteria, etc., and shorten the maturity time , enhance the activity, and accelerate the effect of the combined composting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

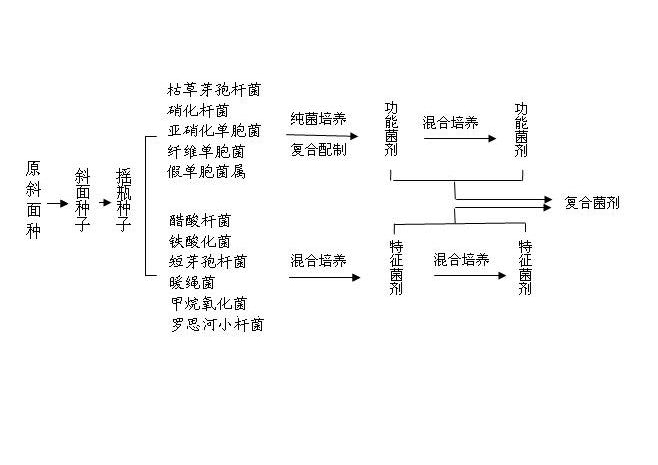

Method used

Image

Examples

Embodiment 1

[0013] Example 1 1. Materials and source strains: Perchlorate-degrading bacteria (Azospira oryzae; DSMZ13638) and warm wire bacteria (Caldilinea aerophila; DSMZ14535) were purchased from the German Culture Collection of Microorganisms (DSMZ).

[0014] Methane-oxidizing bacteria (Methylocella silvestris; ATCC700799), Nitrobacter winogradskyi (ATCC25391), Nitrosomonas europaea (ATCC25391) were purchased from the American Microbial Culture Collection (ATCC).

[0015] Bacillus subtilis (ACCC10619), Bacillus brevis (Brevibacillus brevis; ACCC10248), Cellulomonas cartae (ACCC10527), Pseudomonas sp. (ACCC10677) were purchased from China Agricultural Microbiology Species Resource Bank (ACCC).

[0016] Acetobacterium wieringae (CGMCC 1.2033) was purchased from China General Microorganisms Resource Bank (CGMCC). Rhodanobacter fulvus (CICIM B1950) was purchased from Jiangnan University Microbial Cultures Resource Bank (CICIM) II. Culture Substrate and preparation of slant seed preparati...

Embodiment 2

[0034] Embodiment 2 Application of composite bacterial agent in sludge degradation rate The bacterial agent of the above-mentioned embodiment 1 is applied to the sludge reduction of the Ministry of Environment and Forestry, Gifu County, Japan. The operation method is to add 20 g of sludge containing composite bacterial agent in the test tube, and contrast The group added 4g of normal sludge, added sludge for 36 consecutive days, and removed the supernatant liquid. The following data are obtained, after the addition of bacterial agents, the sludge degradation rate is significantly accelerated, the added sludge is almost completely degraded, and the maximum sludge reduction load is 0.041d -1 , only 0.018d without adding bacteria -1 .

[0035]

Embodiment 3

[0036] Example 3 Application of composite bacterial agent in treating pig farm sewage and rural village sewage The liquid active bacterial agent is mixed with activated sludge to prepare mud-like bacterial agent, and the activated sludge method is used to treat pig farm sewage and rural village sewage. Table 2 and Table 3 show that the mud-like active bacterial agent has a good treatment effect on pig farm sewage and rural village sewage, in which the organic components are almost completely degraded, the removal rate of BOD is over 99%, and the removal of nitrogen and phosphorus is also good. Effect.

[0037] project

[0038] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com