Production process of a dimming film for intelligent dimming glass

A technology of intelligent dimming and production technology, which is applied in the direction of optics, layered products, nonlinear optics, etc., can solve the problems of rough process, localized products without mentioning production products, and formulas that cannot produce qualified products, etc., to achieve barrier Ultraviolet light, reasonable production line and production process, strong automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

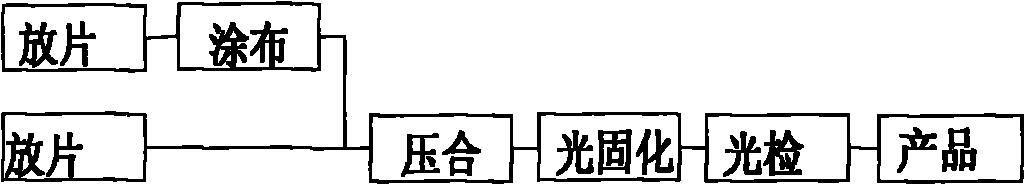

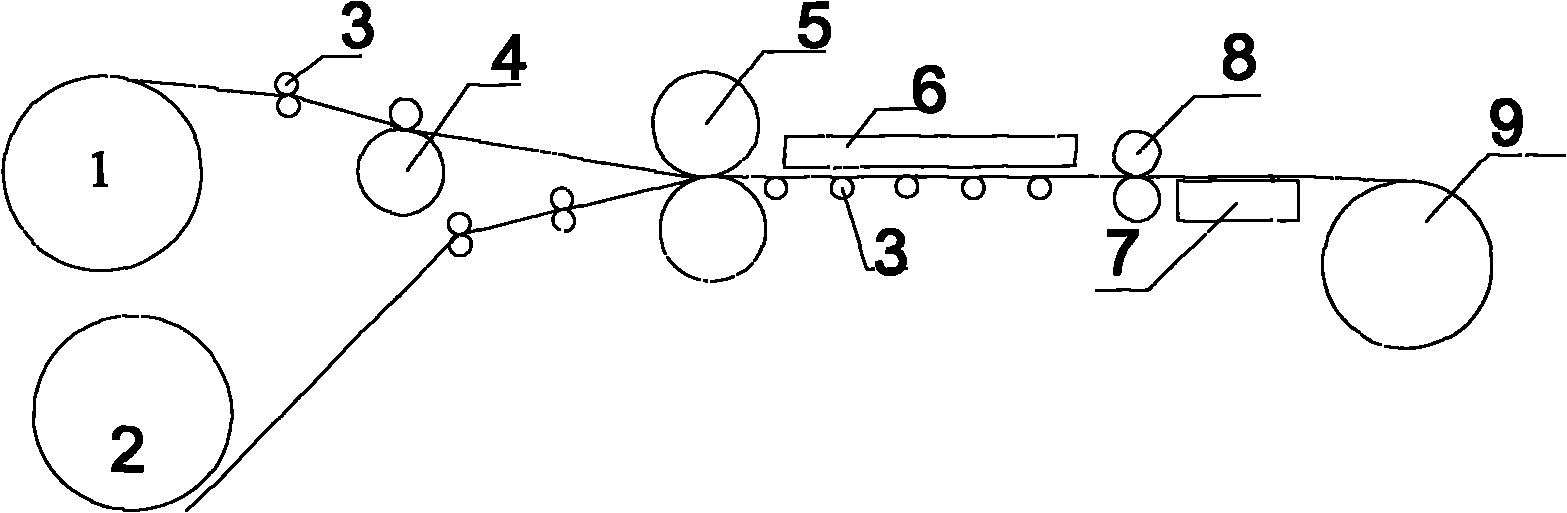

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The production process of the dimming film for this smart dimming glass includes the following steps:

[0023] 1. Using butyl methacrylate monomer as polymer intermediate, cholesteryl pelargonate as monomer liquid crystal and polyethylene as accelerator, the mass ratio is 15%: 85%: 0.5% to configure polymer - Liquid crystal mixture.

[0024] 2. The well-proportioned mixed solution should be fully stirred in the dark and ventilated at a temperature between 35°C and 60°C, with a rotation speed of not less than 4000 rpm and a duration of not less than 10 hours.

[0025] 3. The mixed liquid mixture that has been stirred is applied in a 100,000 / 1,000,000-class dust-free environment, using a chrome alloy coating roller, and the coating thickness is controlled at 15-30 nanometers, and the error accuracy is not more than 1 nanometer. The coating surface of the single-layer ITO conductive film material.

[0026] 4. The film layer in step 3 and another layer of IT...

Embodiment 2

[0028] Embodiment 2: The production process of the dimming film for smart dimming glass includes the following steps:

[0029] 1. Using butyl methacrylate monomer as polymer intermediate, cholesteryl pelargonate as monomer liquid crystal and polyethylene as accelerator, the mass ratio is 15%: 75%: 10% to configure polymer - liquid crystal mixture;

[0030] 2. Mix the well-proportioned liquid mixture at a temperature between 35 °C and 60 °C, with a rotation speed of not less than 4000 rpm and a duration of not less than 10 hours, and fully stirred in the dark and ventilated;

[0031] 3. The mixed liquid mixture that has been stirred is applied in a 100,000 / 1,000,000-class dust-free environment, using a chrome alloy coating roller, and the coating thickness is controlled at 15-30 nanometers, and the error accuracy is not more than 1 nanometer. The coating surface of the single-layer ITO conductive film material.

[0032] 4. The film layer in step 3 and another layer of ITO con...

Embodiment 3

[0034] Embodiment 3: The production process of the dimming film for this smart dimming glass includes the following steps:

[0035] 1. Using butyl methacrylate monomer as polymer intermediate, cholesteryl pelargonate as monomer liquid crystal and polyethylene as accelerator, the mass ratio of 75%: 25%: 0.5% is used to configure polymer - liquid crystal mixture;

[0036] 2. Mix the well-proportioned liquid mixture at a temperature between 35 °C and 60 °C, with a rotation speed of not less than 4000 rpm and a duration of not less than 10 hours, and fully stirred in the dark and ventilated;

[0037] 3. The mixed liquid mixture that has been stirred is applied in a 100,000 / 1,000,000-class dust-free environment, using a chrome alloy coating roller, and the coating thickness is controlled at 15-30 nanometers, and the error accuracy is not more than 1 nanometer. Coated surface of single-layer ITO conductive film;

[0038] 4. The film layer in step 3 and another layer of ITO conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com