Method for preparing submicron lamellar magnesium hydroxide by intensifying alkali

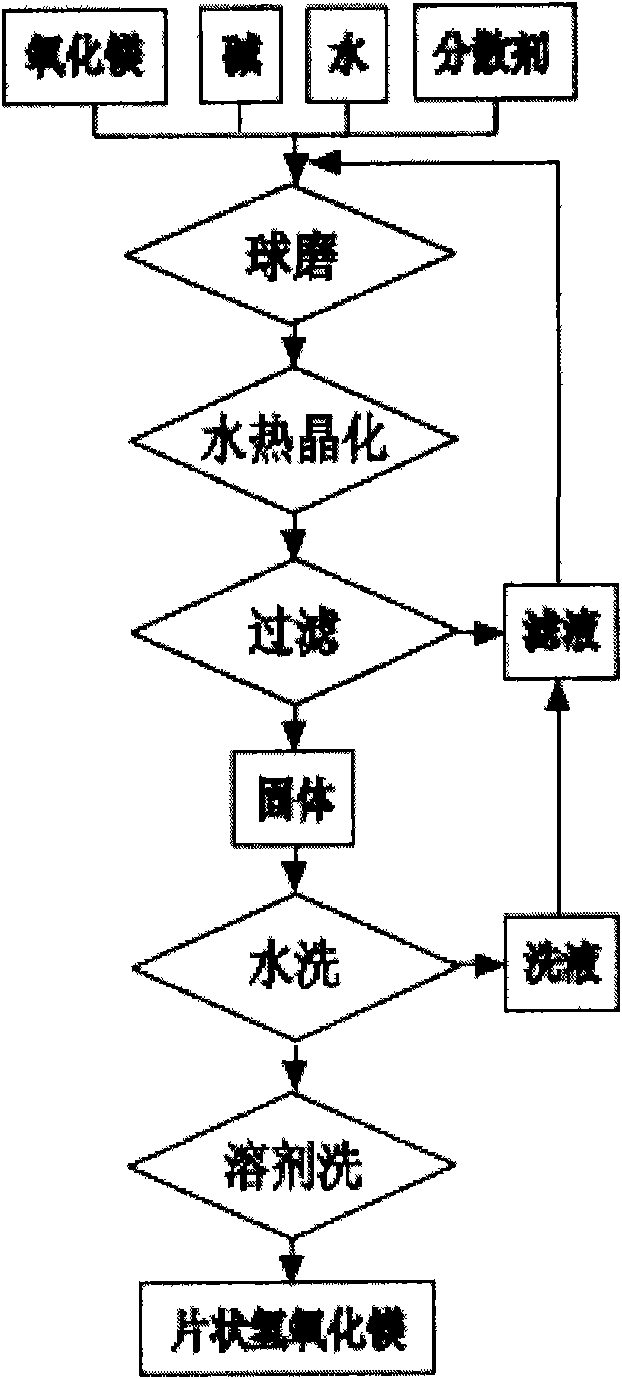

A magnesium hydroxide, sub-micron technology, applied in the direction of magnesium hydroxide, etc., can solve the problems that the crystallinity and shape of magnesium hydroxide are difficult to meet the requirements of flake magnesium hydroxide flame retardants, and the cost of magnesium hydroxide increases. Achieve the effects of saving alkali for precipitation, reducing energy consumption and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The composition of magnesium oxide is 98.5% of MgO, and the loss on ignition is less than 4.5%.

[0043] Mix 20.2 g of the above magnesium oxide powder, 10 g of sodium hydroxide, 0.5 g of polyvinylpyrrolidone and 100.0 g of water;

[0044] Transfer to a 500ml nylon ball mill jar, and use 100g of dead-burned magnesia balls with a diameter of 6mm to mill for 4 hours at a speed of 400r / min to form a slurry to be crystallized.

[0045] Pour the above slurry to be crystallized into a PTFE-lined 200ml pressure bomb, and crystallize at 200°C for 4 hours (h);

[0046] Suction filter the above reaction slurry at room temperature, wash it three times with deionized water, wash it once with industrial ethanol, and dry it in an oven at 120°C for 3 hours to obtain flake magnesium hydroxide.

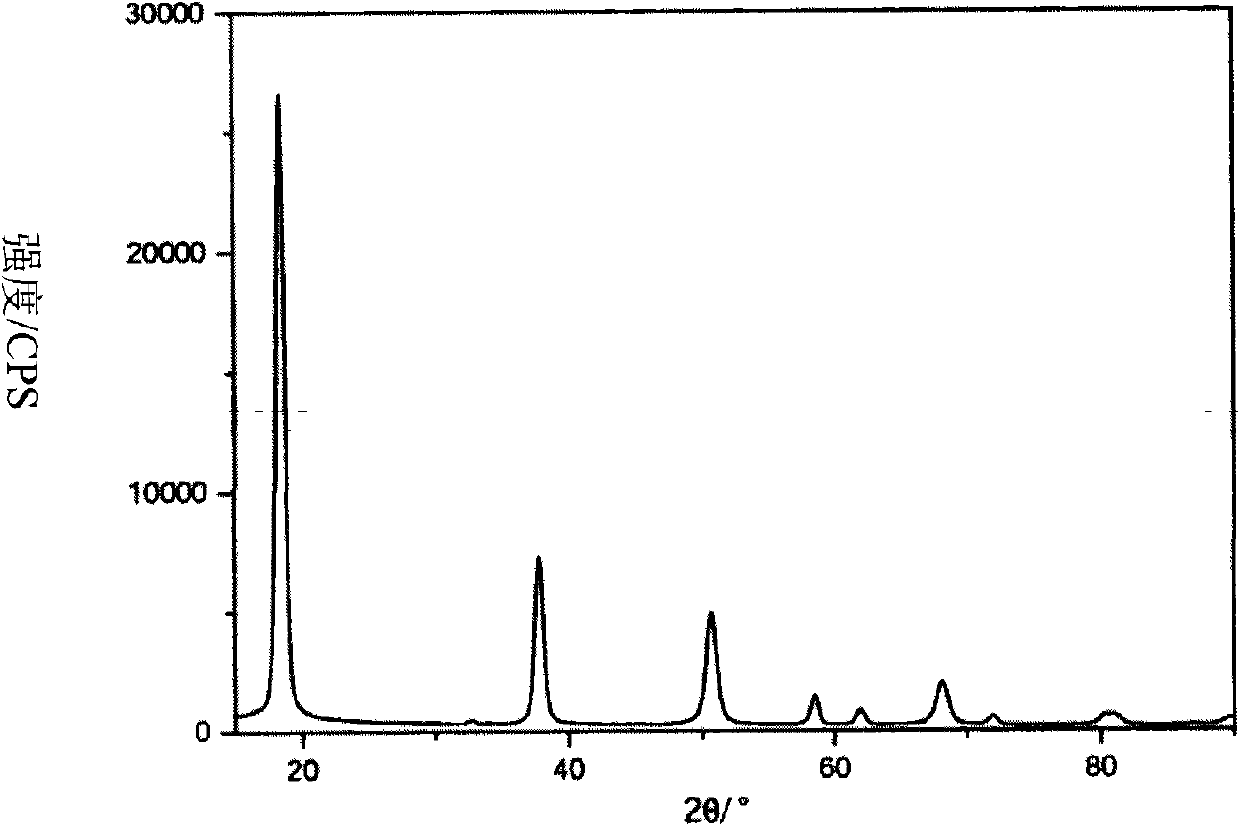

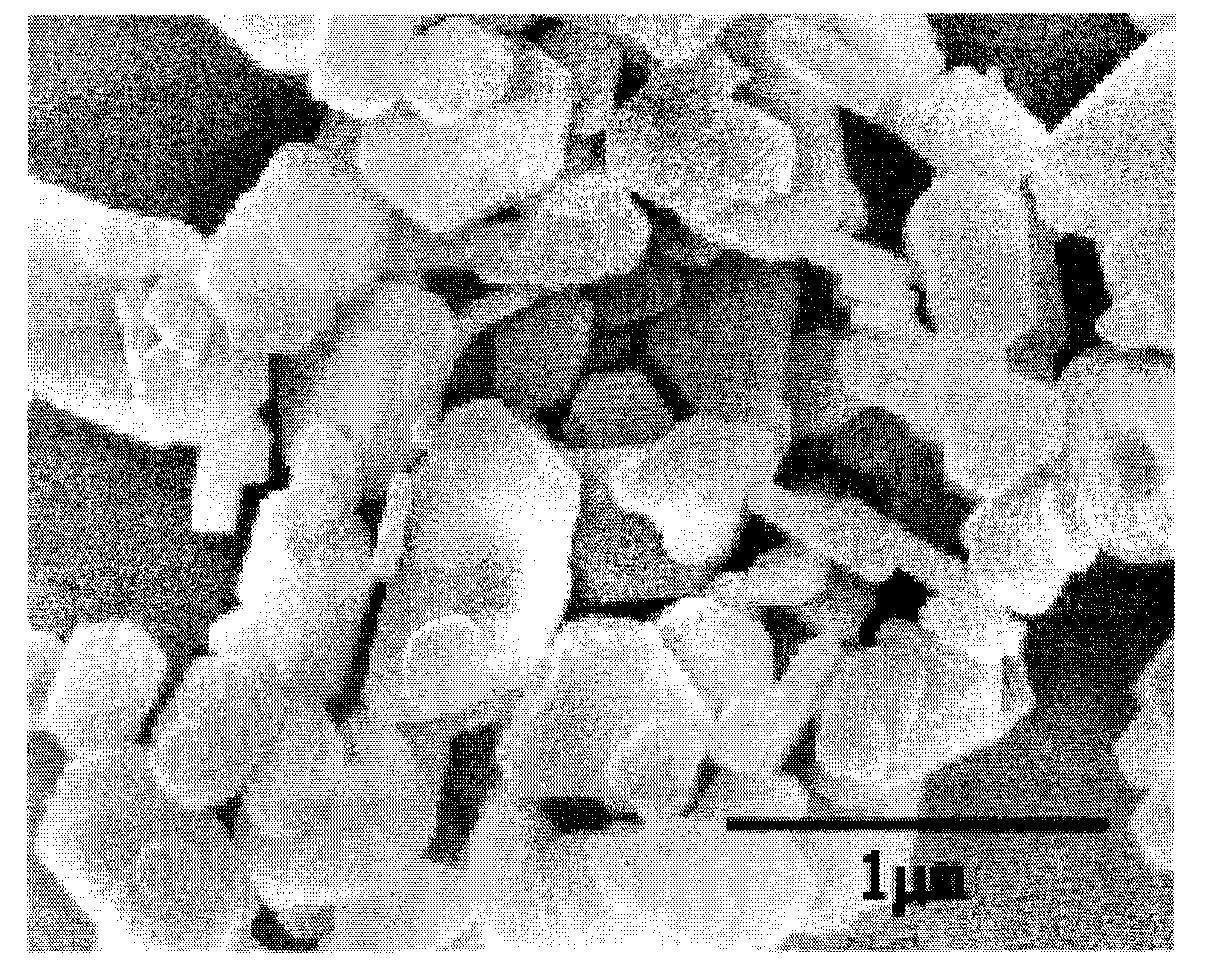

[0047] The XRD diffraction pattern of gained magnesium hydroxide structure is as figure 2 As shown, the shape is as image 3 shown.

Embodiment 2

[0049]Mix 1kg of the above magnesium oxide powder, 200ml of ammonia water, 5g of polyvinyl alcohol and 5kg of water;

[0050] Transfer to the SX-30 stirring ball mill, and use 5 kg of dead-burned magnesia balls with a diameter of 6 mm to grind for 8 hours with a power of 2 kw to form a slurry to be crystallized.

[0051] Transfer the above-mentioned slurry to be crystallized into a 10L stirred reactor, and crystallize at 160°C for 10h,

[0052] Suction filter the above reaction slurry at room temperature, wash it three times with deionized water, wash it once with industrial ethanol, and dry it in an oven at 120°C for 3 hours to obtain flake magnesium hydroxide.

Embodiment 3

[0054] Mix 20.2 g of the above magnesium oxide powder, 10 g of diethylamine, 0.5 g of polyvinylpyrrolidone and 100.0 g of water;

[0055] Transfer to a 500ml nylon ball mill jar, and use 100g of dead-burned magnesia balls with a diameter of 6mm to mill for 4 hours at a speed of 400r / min to form a slurry to be crystallized.

[0056] Pour the above-mentioned slurry to be crystallized into a PTFE-lined 200ml pressure bomb, and crystallize at 200°C for 4 hours;

[0057] Suction filter the above reaction slurry at room temperature, wash it three times with deionized water, wash it once with industrial ethanol, and dry it in an oven at 120°C for 3 hours to obtain flake magnesium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com