Method for bleaching fibers

A fiber and derivative technology, applied in the field of fiber bleaching, can solve problems such as poor nip rate, uneven general degree, etc., and achieve the effects of reducing costs, reducing losses, and reducing burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Pad-dye (three dips and three pads) the following solution on the raw fabric of 100% cotton cloth (for bleaching before dyeing), use a liquid manipulator to squeeze the liquid to reach a 100% excess rate, and wrap it with plastic cloth after rolling , placed at room temperature for 24 hours, then washed with hot water at 90-95°C for 10-20 minutes at a bath ratio of 1:10, and then washed in a 60°C bath of 1 g / L acetic acid at a bath ratio of 1:10 Neutralize by treating for 5 minutes, and then wash with hot water and normal temperature water to complete the bleaching process.

[0071]

[0072] Lactic acid 5g / L

[0073] Hydrogen peroxide solution (35%) 45g / L

[0074] Catalyst for peracid generation (Note 1) 5g / L

[0075] Sodium hydroxide (solid) 20g / L

[0076] Alkaline bath stabilizer (note 2) 40g / L

[0077] Soaking and scouring agent (Note 3) 20g / L

[0078] Oxidation Desizing Agent 25g / L

[0079] Chelating agent 2g / L

[0080] pH 12.5

Embodiment 2

[0082] Pad-dye (three dips and three pads) the following solution on the raw fabric of 100% cotton towel (for whitening treatment), use a liquid manipulator to squeeze the liquid to reach a 100% excess rate, and stack it on the transport vehicle Wrap it with plastic cloth and place it at room temperature for 48 hours, then wash it with hot water at 90-95°C for 10-20 minutes at a bath ratio of 1:10, and then wash it with 1 g / L acetic acid at a bath ratio of 1:10. Treatment in a 60° C. bath for 5 minutes was performed to neutralize, and then hot water washing and normal temperature water washing were performed to complete the bleaching treatment.

[0083]

[0084] Lactic acid 15g / L

[0085] Hydrogen peroxide solution (35%) 135g / L

[0086] Catalyst for peracid generation (Note 1) 15g / L

[0087] Sodium hydroxide (solid) 20g / L

[0088] Alkaline bath stabilizer (note 2) 40g / L

[0089] Soaking and scouring agent (Note 3) 30g / L

[0090] Oxidation Desizing Agent 25g / L

[0091] ...

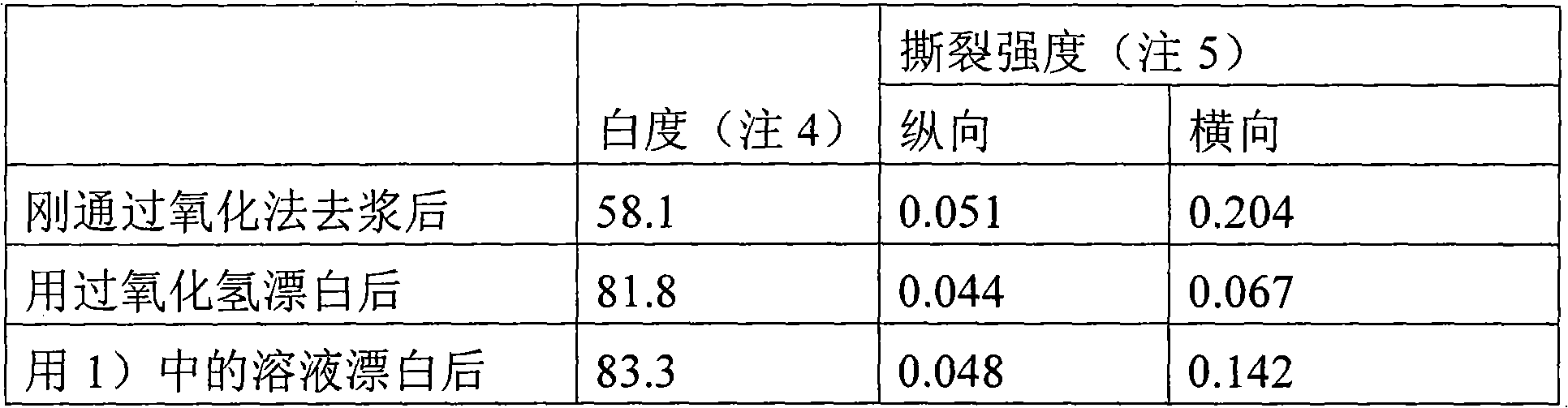

Embodiment 3

[0094] Pad-dye the following solution (two dipping and two padding) on the raw fabric of 100% cotton fabric (for bleaching before dyeing), use a liquid manipulator to squeeze the liquid to reach a 100% puffing rate, and stack it on the transport vehicle Wrap it with plastic cloth and place it at room temperature for 24 hours, then wash it with hot water at 90-95°C for 10-20 minutes (twice) with a bath ratio of 1:10, and then wash it at 1 g / The solution was neutralized by being treated in a 60° C. bath with L of acetic acid for 5 minutes, and then washed with hot water and washed with normal temperature water to complete the bleaching treatment.

[0095]

[0096] Lactic acid 5g / L

[0097] Hydrogen peroxide solution (35%) 45g / L

[0098] Catalyst for peracid generation (Note 1) 5g / L

[0099] Sodium hydroxide (solid) 20g / L

[0100] Alkaline bath stabilizer (note 2) 40g / L

[0101] Soaking and scouring agent (Note 3) 30g / L

[0102] Chelating agent 2g / L

[0103] pH 12.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com