Manufacturing method for nanowire with CuO/ZnO core/shell structure

A manufacturing method and nanowire technology, applied in the field of nanophotonics, can solve the problems of large lattice mismatch of ZnO crystals and difficult realization of nanowires, and achieve the effects of uniform diameter and length distribution, improved efficiency and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

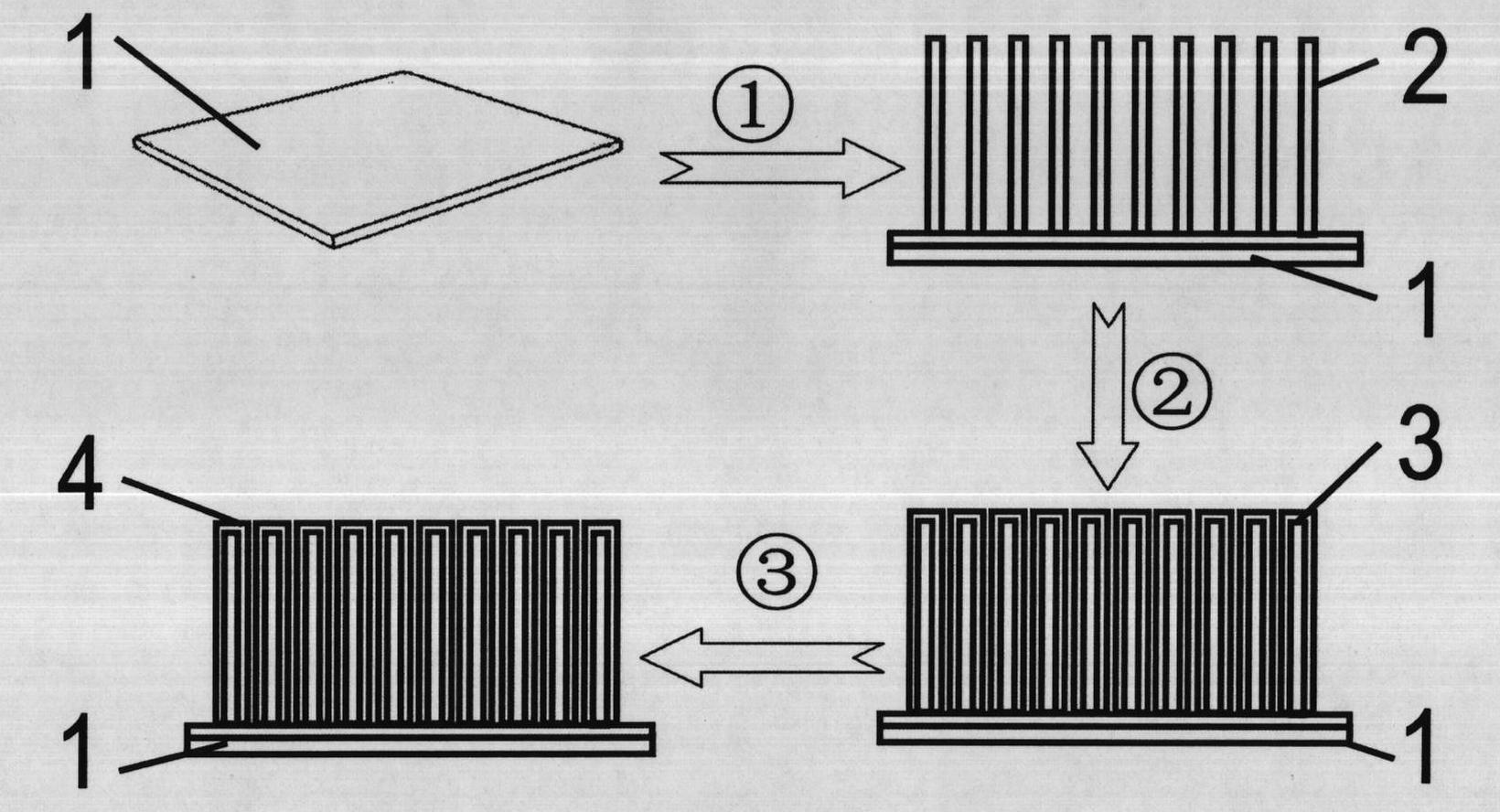

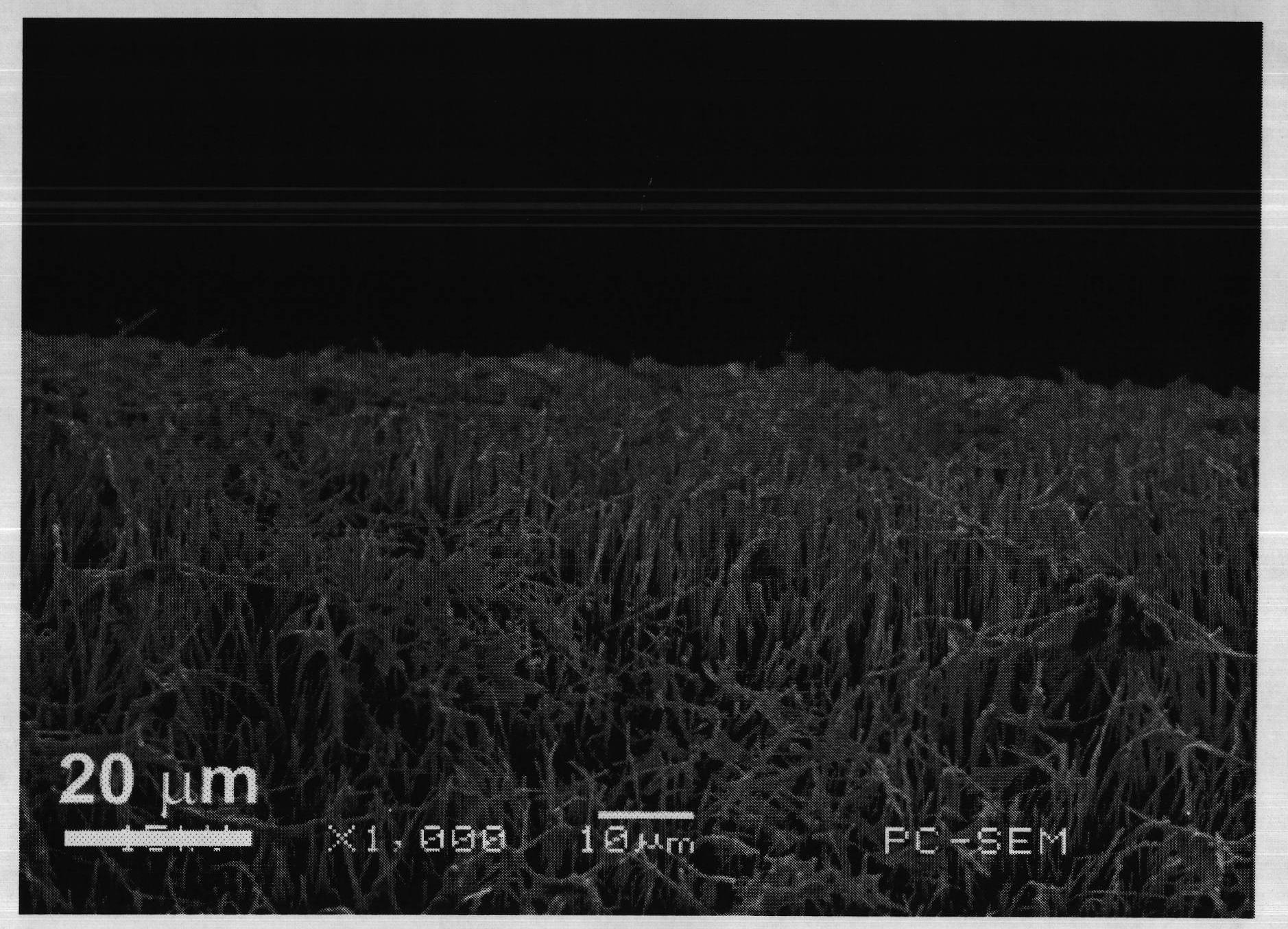

[0036] First, cut high-purity (99.9%) copper foil into small pieces of copper foil with a width of 10mm x 20mm length x 0.5mm thickness, flatten them with a glass or metal plate, and place the flat copper foil in alcohol and acetone at a volume of 1: Ultrasonic cleaning in a mixture of 1 ratio for 3 minutes to remove the dirt adhering to the surface, put the copper foil cleaned with alcohol and acetone into 1mol / L dilute hydrochloric acid solution for 3 minutes to remove the oxide on the surface, take out Afterwards, rinse with deionized water for several times, and then dry naturally in the air; secondly, attach the cleaned and dried copper foil to the quartz plate and place it on an electric furnace at 500°C for 4 hours in the air and then cool it rapidly to At room temperature, the CuO nanowire array was obtained; again, on the copper foil substrate on which the CuO nanowire array had been grown, drop 5 drops of an ethanol solution saturated with zinc acetate on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com