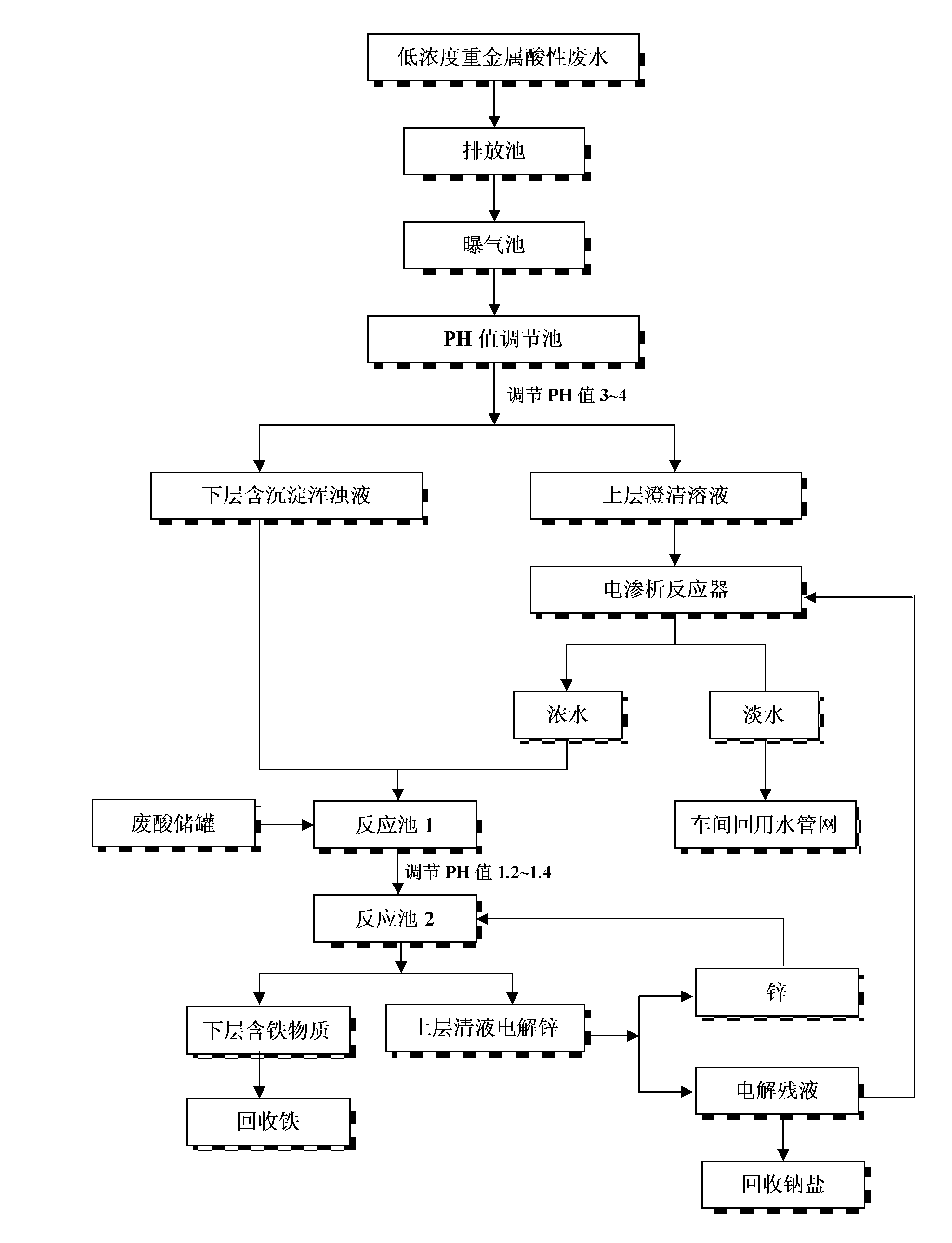

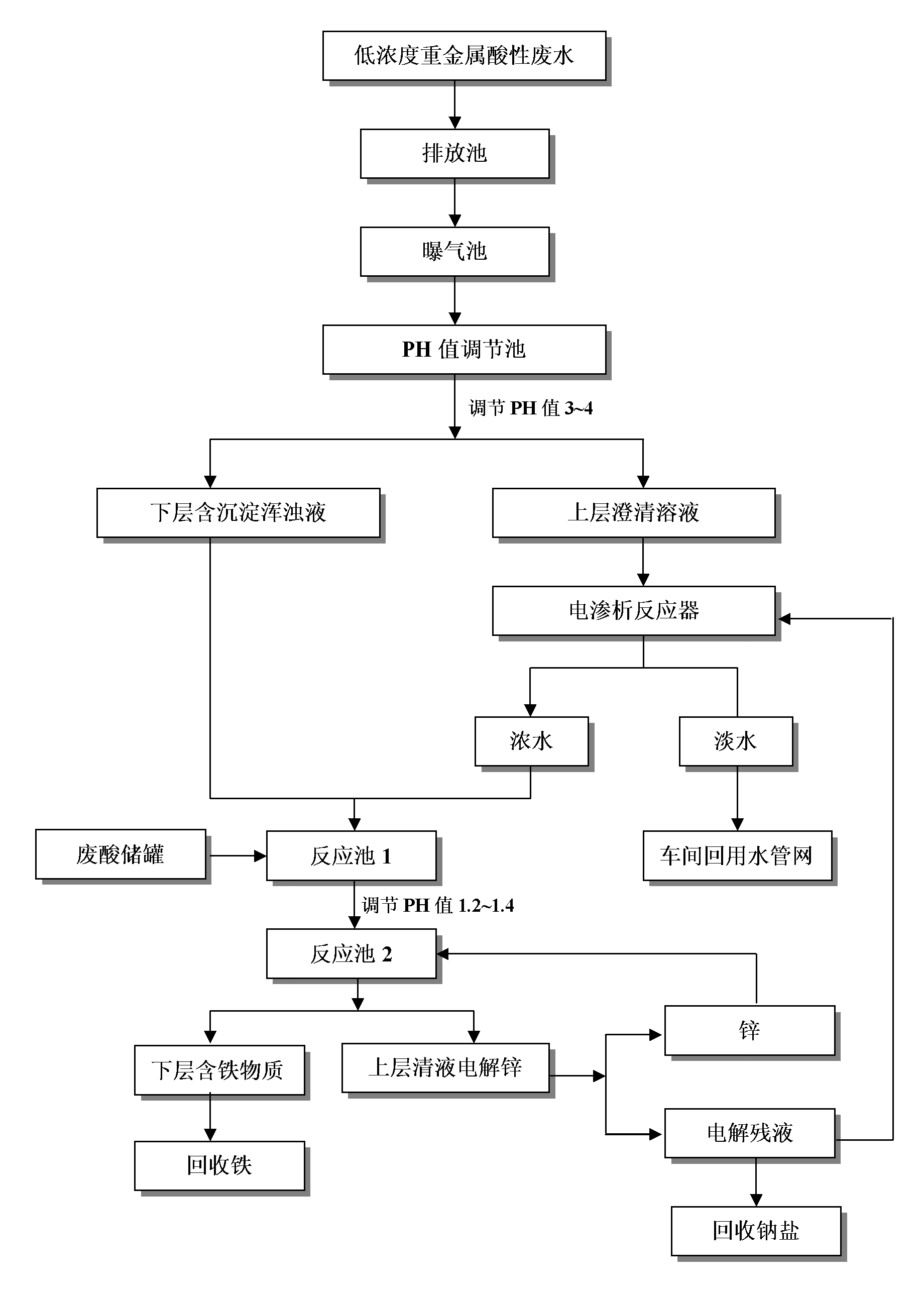

Closed cyclic processing method for low-concentration acid wastewater during industrial production

A technology of acidic wastewater and closed cycle, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, process efficiency improvement, etc. It can solve the problems of high iron ion concentration and inability to dispose of sludge, and achieve an increase The effect of mass transfer speed, elimination of poor quality of discharge water from the connection pipe, and improvement of current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Take 60kg of low-concentration heavy metal acidic wastewater discharged during the production of metal products, flow into the discharge tank, and drive it with a water pump, and the low-concentration heavy metal acidic wastewater flows into the aeration tank. Among them, the iron ion concentration is 363mg / L, the zinc ion concentration is 13mg / L, and the pH=1.77.

[0029] 2) Aeration is performed in the aeration tank to aerate the low-concentration heavy metal acidic wastewater. After oxidizing for 3 to 5 hours through aeration, the low-concentration heavy metal acidic wastewater is pumped into the PH value adjustment tank by driving the water pump.

[0030] 3) Add 60g of industrial solid sodium hydroxide or a saturated solution of sodium hydroxide containing the same amount of solute to the pH adjustment pool, and adjust the pH of the solution to 3~4 under stirring. At this pH value, iron ions in the solution will precipitate , Zinc ions do not produce precipitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com