Manufacture method of installed and welded shearing tool of heavy forging

A large-scale forging and manufacturing method technology, which is applied in the field of forging tool manufacturing, can solve the problems of not being able to enter the practical stage, large welding deformation, and easy welding cracks, etc., so as to save high-quality high-speed tool steel materials and have strong resistance to high-temperature plastic deformation. , Good effect of high temperature wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

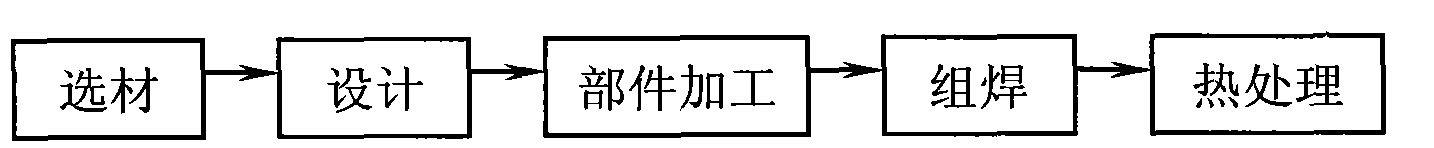

[0021] Example 1. Combine figure 1 The specific implementation of the group welding cutting tool for large forgings proposed in the present invention is that the group welding cutting tool is composed of two different materials. Among them, the cutting edge part (1) of the group welding cutting tool adopts high temperature resistance and creep resistance. High-speed tool steel material with good variable performance, the support matrix (2) of the group welding shearing tool is made of ordinary heat-resistant alloy steel material, the cutting edge part (1) and the support matrix (2) are machined by milling, and then high-energy electronics Beam welding, and then heat treatment to make the finished product. Combine Figure 5 , Now take as an example the in-line cutting edge (1-1) of a large forging with a thickness of δ30mm. The specific steps are as follows:

[0022] Step 1. Material selection. Such as Figure 5 As shown, the cutting edge part (1) of the group welding cutting to...

Embodiment 2

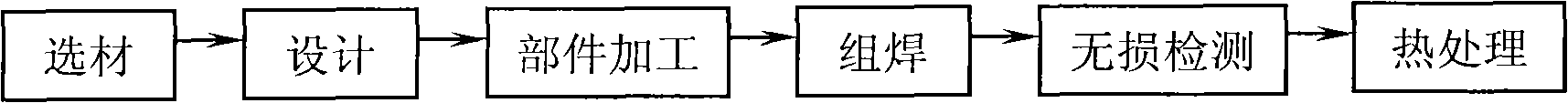

[0027] Example 2. Combine figure 1 The specific implementation of the group welding cutting tool for large forgings proposed in the present invention is that the group welding cutting tool is composed of two different materials. Among them, the cutting edge part (1) of the group welding cutting tool adopts high temperature resistance and creep resistance. High-speed tool steel material with good variable performance, the support matrix (2) of the group welding shearing tool is made of ordinary heat-resistant alloy steel material, the cutting edge part (1) and the support matrix (2) are machined by milling, and then high-energy electronics Beam welding, and then heat treatment to make the finished product. Combine Image 6 Now take the arc-shaped cutting edge (1-2) of a large forging with a thickness of δ100mm as an example. The specific steps are as follows:

[0028] Step 1. Material selection. Such as Image 6 As shown, the cutting edge part (1) of the arc-shaped cutting edge ...

Embodiment 3

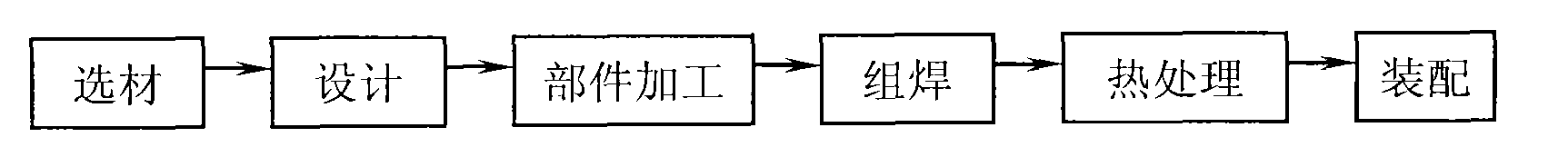

[0033] Example 3. Combine figure 1 The specific implementation of the group welding cutting tool for large forgings proposed in the present invention is that the group welding cutting tool is composed of two different materials. Among them, the cutting edge part (1) of the group welding cutting tool adopts high temperature resistance and creep resistance. High-speed tool steel material with good variable performance, the support matrix (2) of the group welding shearing tool is made of ordinary heat-resistant alloy steel material, the cutting edge part (1) and the support matrix (2) are machined by milling, and then high-energy electronics Beam welding, and then heat treatment to make the finished product. Combine Figure 7 , Now take the group welding shear cutter for the arc tapered cutting edge (1-3) of the large forging with a thickness of δ80mm as an example, the specific steps are:

[0034] Step 1. Material selection. Such as Figure 7 As shown, the cutting edge part (1) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com