Preparation method of platinum nanoparticle loaded graphene

A technology of platinum nanoparticles and graphene, applied in the field of preparation of platinum nanoparticles supported on graphene, to achieve high density and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

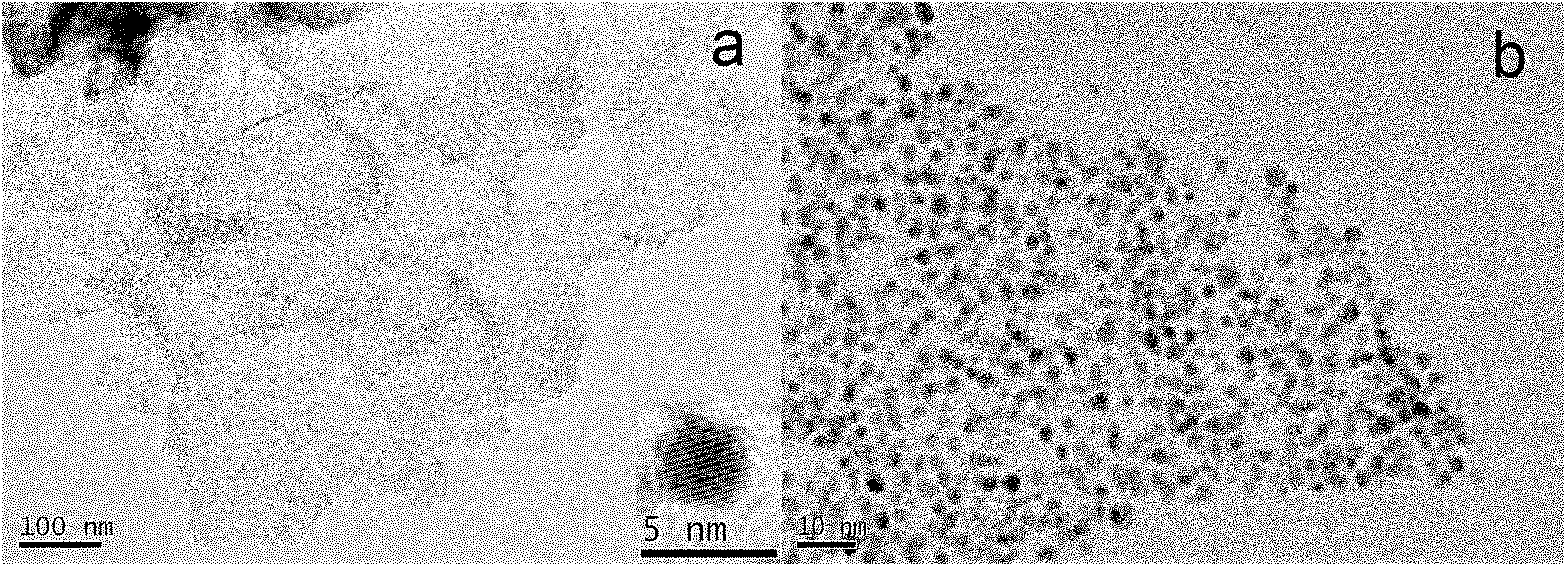

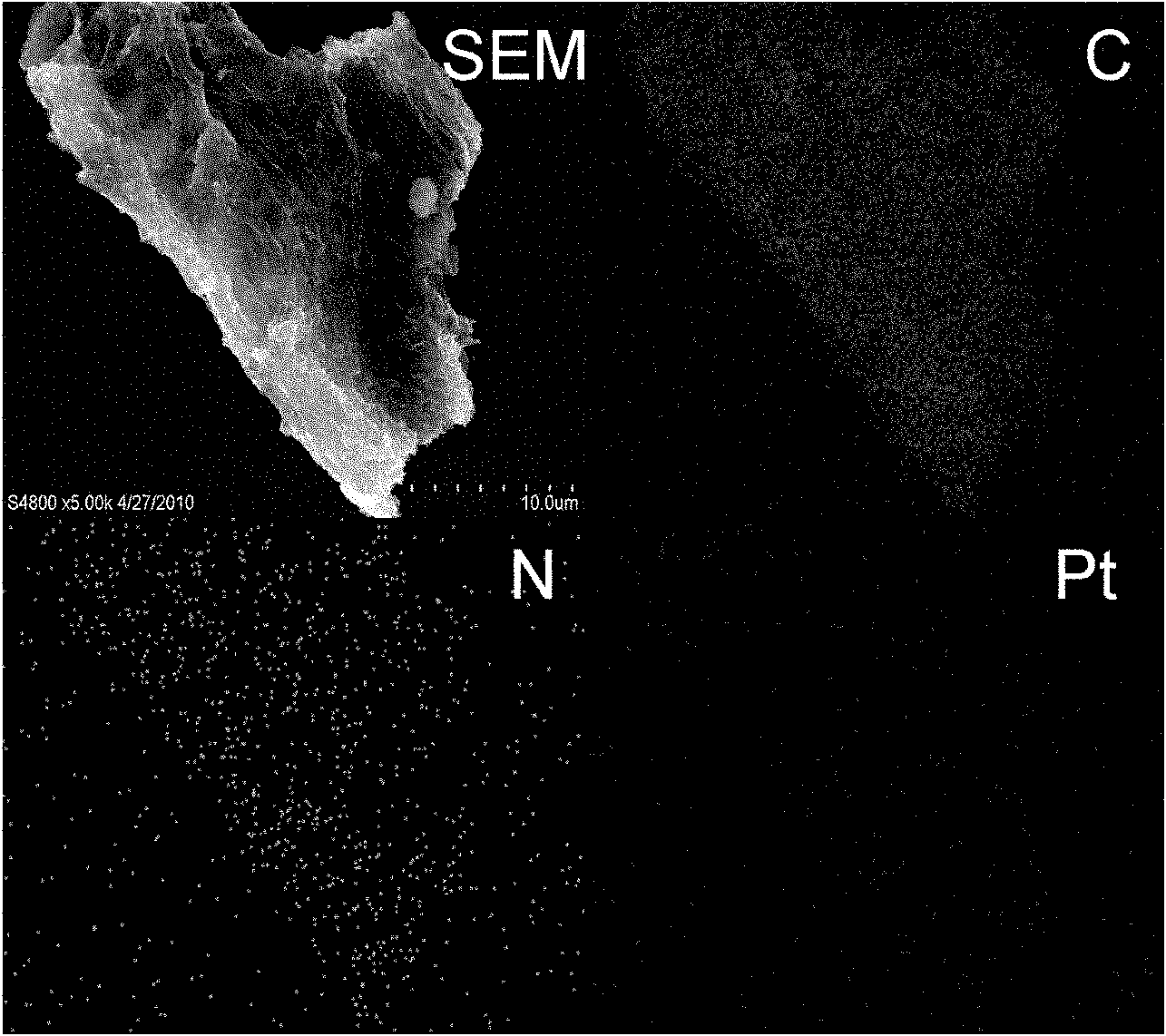

[0023] A typical procedure for preparing a composite of high-density supported platinum nanoparticles on chemically reduced graphene is as follows:

[0024] (1) Hydrazine chemical reduction of graphite oxide: hydrazine was used to reduce graphite oxide prepared by the Hummers method at 95° C., reacted for one hour, washed and freeze-dried to obtain reduced graphene.

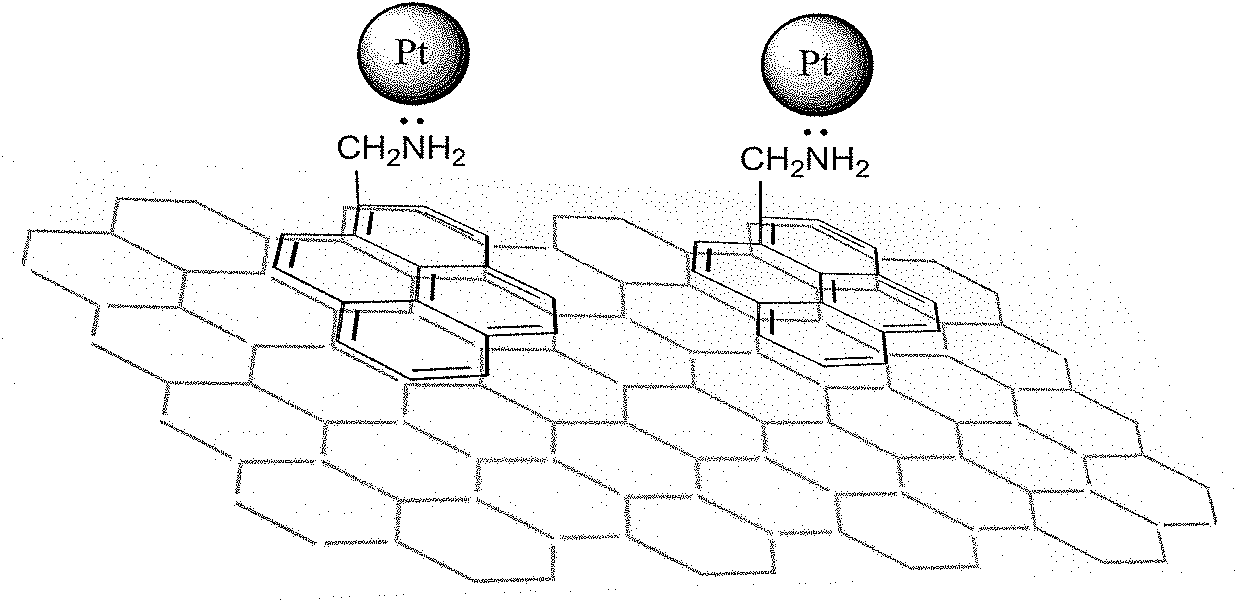

[0025] (2) A layer of 1-pyrenemethylamine is self-assembled on the surface of graphene, and 1-pyrenemethylamine utilizes the interaction of π-π to form a self-assembled film on the surface of graphene: 8 mg of reduced graphene is ultrasonically dispersed in 80 ml of ethyl alcohol Diol solution, add 12ml concentration of 10 -3 The ethylene glycol solution of 1-pyrenemethylamine of M was stirred for 30 minutes (just enough at room temperature). Self-assembly of 1-pyrenemethylamine onto graphene surfaces

[0026] (3) Ethylene glycol reduces chloroplatinic acid at a pH of 8-9 at 160° C. to prepare platinum nanopart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com