Quizalofop-p-ethyl emulsion in water and preparation method thereof

A technology of quizalofop-p-ethyl and water-emulsion, which is applied in the field of quizalofop-p-p-p-p water emulsion and its preparation, can solve the problems of harming health, environmental pollution, high manufacturing cost, etc., achieve less environmental pollution, reduce production cost, and reduce pollution and residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

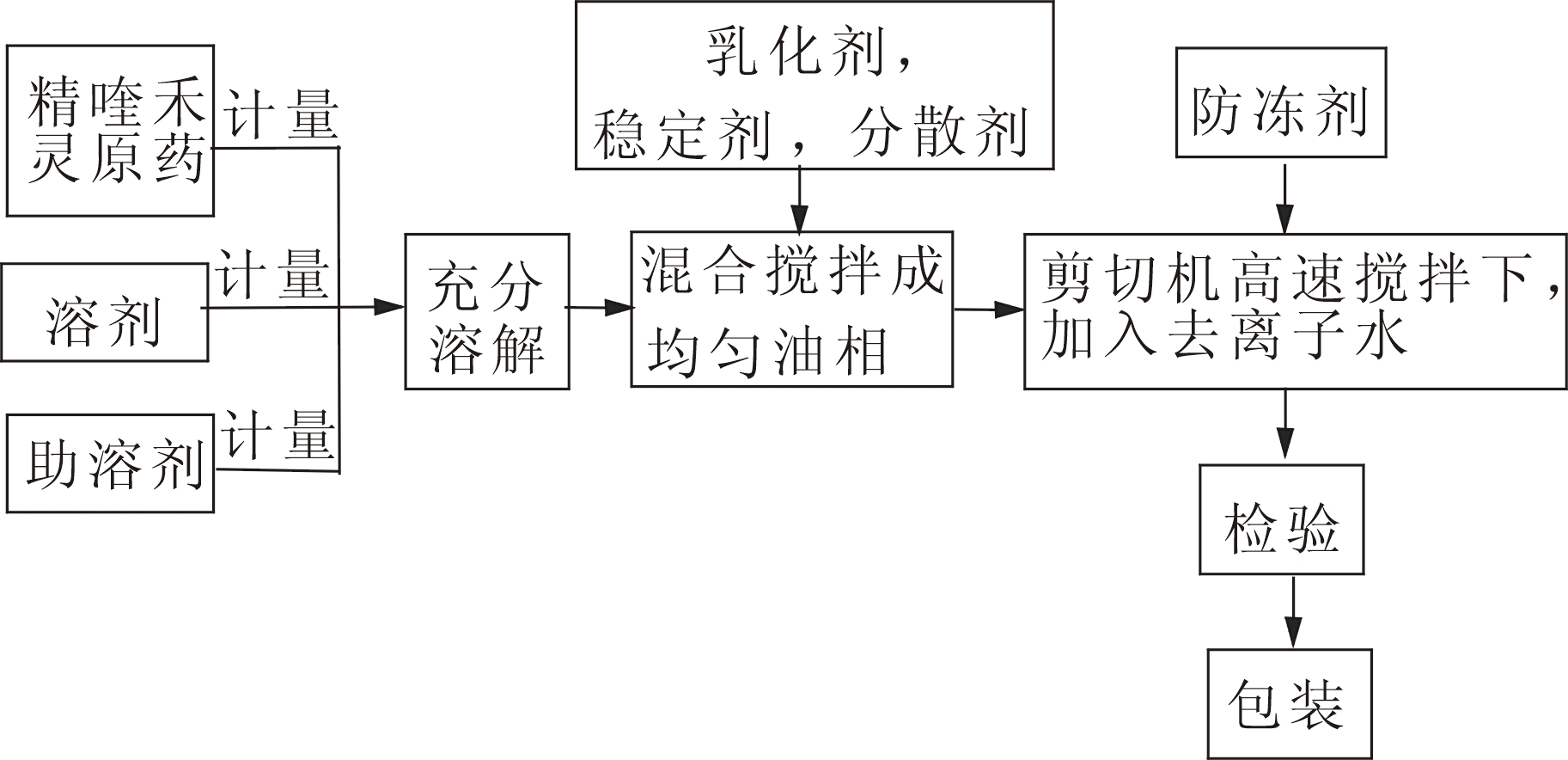

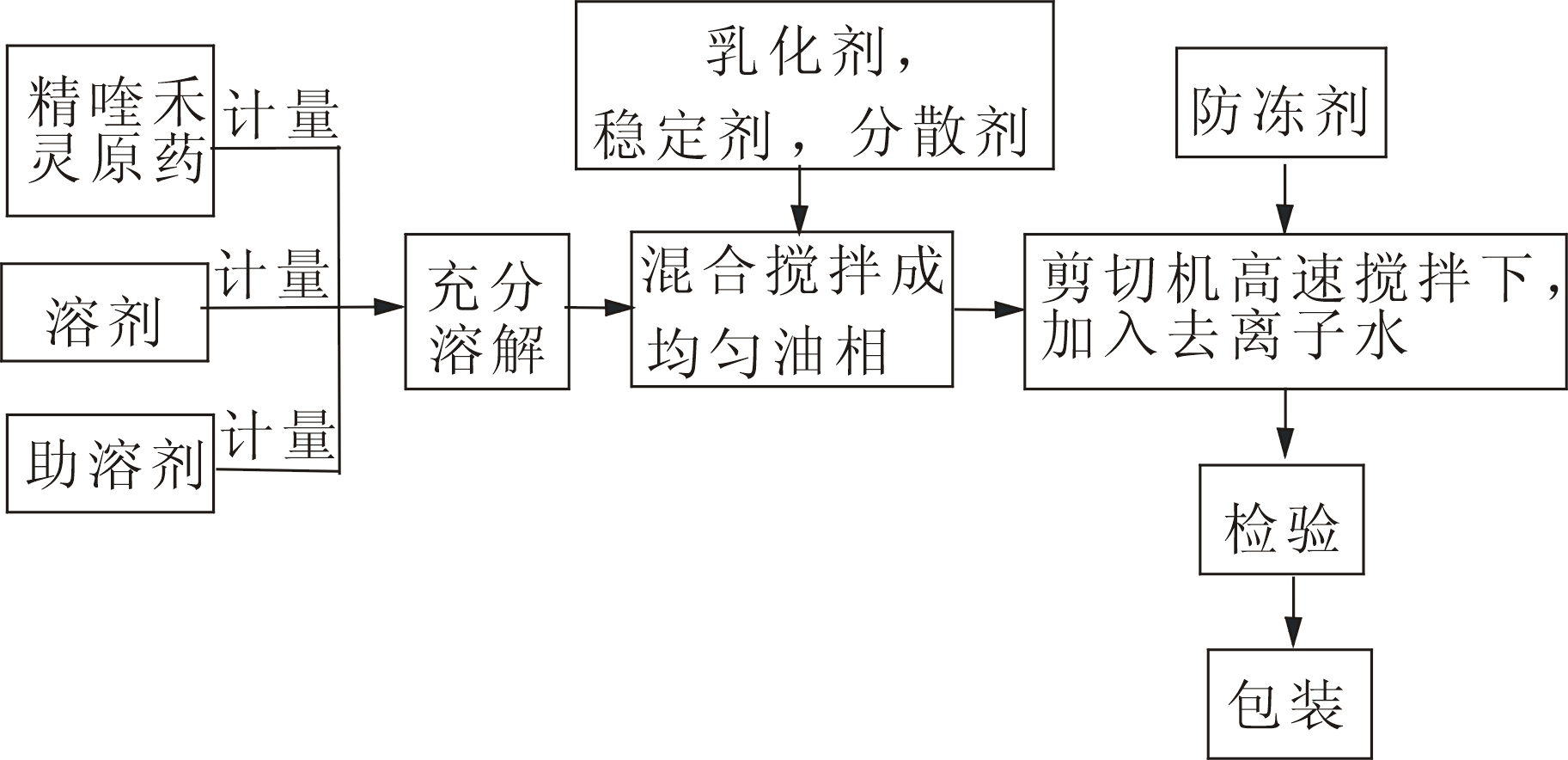

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: 5% quizalofop-p-ethyl, 12% xylene, the two are mixed and fully dissolved, then add 3% castor oil polyoxyethylene ether, 2% fatty alcohol polyoxyethylene ether, alkylphenol formaldehyde resin polyoxyethylene 1% ether sulfate, 2% pyrogallic acid, and 2% peanut oil to obtain the oil phase; 4% ethylene glycol was thrown into the remaining deionized water, and the water phase was made after fully stirring in the preparation kettle. phase was slowly added to the water phase, and sheared at 6000 rpm for 30 minutes to obtain a 5% quizalofop-p-ethyl emulsion in water.

Embodiment 2

[0020] Embodiment 2: Quizalofop-p-ethyl 10%, xylene 10%, diethyl phthalate 10%, the three are mixed and fully dissolved; then add polyoxyethylene sorbitan fatty acid ketone 2%, maleic diethyl ether Di-sec-octyl sodium sulfonate 1%, alkylphenol formaldehyde resin polyoxyethylene ether sulfate 1.5% (instructions, dispersant is added here), antioxidant 264 2%, peanut oil 4%, to obtain the oil phase; glycerin Put 4% alcohol into deionized water, stir fully in the preparation kettle to make the water phase, turn on the stirring, slowly add the oil phase to the water phase, cut at 6000 rpm for 15 minutes, and obtain 10% quinagra Spiritual water emulsion.

Embodiment 3

[0021] Example 3: Quizalofop-p-ethyl 20%, N-octylpyrrolidone 10%, aromatic hydrocarbon solvent Solvesso150 25% (aromatic hydrocarbon solvent Solvesso150 is a product of ExxonMobil, USA), the three are mixed and fully dissolved, and then castor oil is added Polyoxyethylene ether 4%, polyoxyethylene sorbitan fatty acid ketone 2%, fatty alcohol polyoxyethylene ether 1%, alkylphenol formaldehyde resin polyoxyethylene ether sulfate 1%, epoxy soybean oil 5% to obtain oil Phase; Glycerol 4% is fully stirred in the preparation kettle to make a water phase. After the stirring is turned on, the oil phase is slowly added to the water phase, and the 6000 rpm shears for 20 minutes to obtain 20% quizalofop-ethyl water emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com