Method for removing impurities from cassava raw material

A cassava and raw material technology, applied in biofuels, fermentation, etc., can solve problems such as poor quality and low yield, achieve the effects of reducing losses, improving the speed of impurity removal, and preventing wear and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

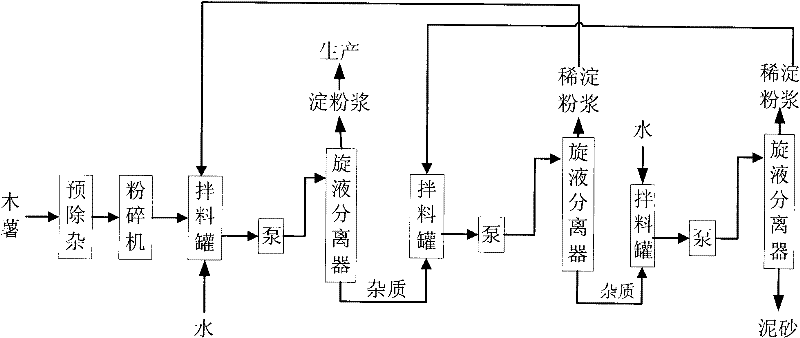

Image

Examples

Embodiment 1

[0022] According to the technical scheme provided by the invention, a method for removing impurities from cassava raw materials adopts the following process steps:

[0023] 1. Pre-removal of impurities: take 1t of cassava raw materials, first pass through a grid sieve to remove impurities such as packaging bags and hemp ropes, and then remove iron through an electromagnetic iron remover;

[0024] 2. Crushing: After iron removal, the cassava enters the phase crusher for coarse crushing, and the coarsely crushed cassava material passes through the 8mm sieve plate; then enters the fine crusher, and the finely crushed cassava particles pass through the 1.5mm sieve;

[0025] 3. Mixing material: the crushed cassava raw material enters the mixing tank, then adds the thin starch slurry in step 5 for slurry mixing, and adds 0.5t of fresh water to ensure that the liquid-solid mass ratio of the slurry is 2.5:1;

[0026] 4. Primary impurity removal: the slurry obtained in step 3 is pumped...

Embodiment 2

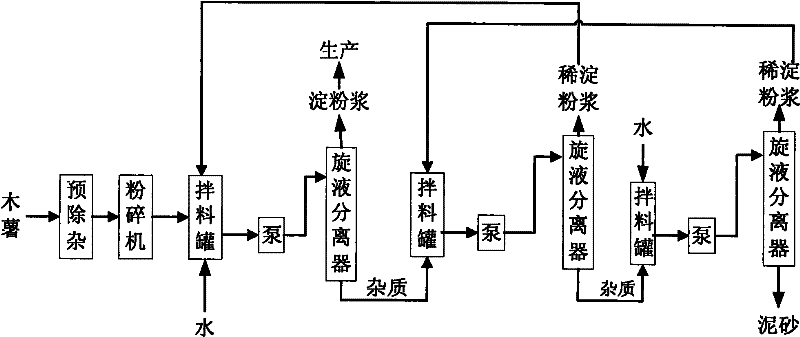

[0029] The difference from the first embodiment above is that in this embodiment, a three-stage hydrocyclone separation and impurity removal method is adopted. According to the technical solution provided by the present invention, a method for removing impurities from cassava raw materials adopts the following process steps:

[0030] 1. Pre-removal of impurities: Take 1t of cassava raw materials, first pass through a grid sieve to remove impurities such as packaging bags and hemp ropes, and then remove iron through an electromagnetic iron remover;

[0031] 2. Crushing: After iron removal, the cassava enters the coarse crusher for coarse crushing, and the coarsely crushed cassava material passes through a 10mm sieve plate; then enters the fine crusher, and the finely crushed cassava particles pass through a 1.5mm sieve;

[0032] 3. Mixing material: enter the mixing tank through the pulverized cassava raw material, then add the thin starch slurry in step 5 to adjust the slurry, a...

Embodiment 3

[0037] The difference from the first and / or second examples above is that in this example, a four-stage hydrocyclone separation method is adopted, and according to the technical solution provided by the present invention, a method for removing impurities from cassava raw materials adopts the following process steps :

[0038] 1. Pre-removal of impurities: Take 1t of cassava raw materials, first pass through a grid sieve to remove impurities such as packaging bags and hemp ropes, and then remove iron through an electromagnetic iron remover;

[0039] 2. Crushing: After iron removal, the cassava enters the coarse crusher for coarse crushing, and the coarsely crushed cassava material passes through a 10mm sieve plate; then enters the fine crusher, and the finely crushed cassava particles pass through a 2mm sieve;

[0040] 3. Mixing material: enter the mixing tank through the pulverized cassava raw material, then add the dilute starch slurry in step 5 to adjust the slurry, and add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com