Heat-resisting polyethylene plastic pipe with high heat conductivity

A heat-resistant polyethylene, high thermal conductivity technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor impact toughness, low heat transfer efficiency, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

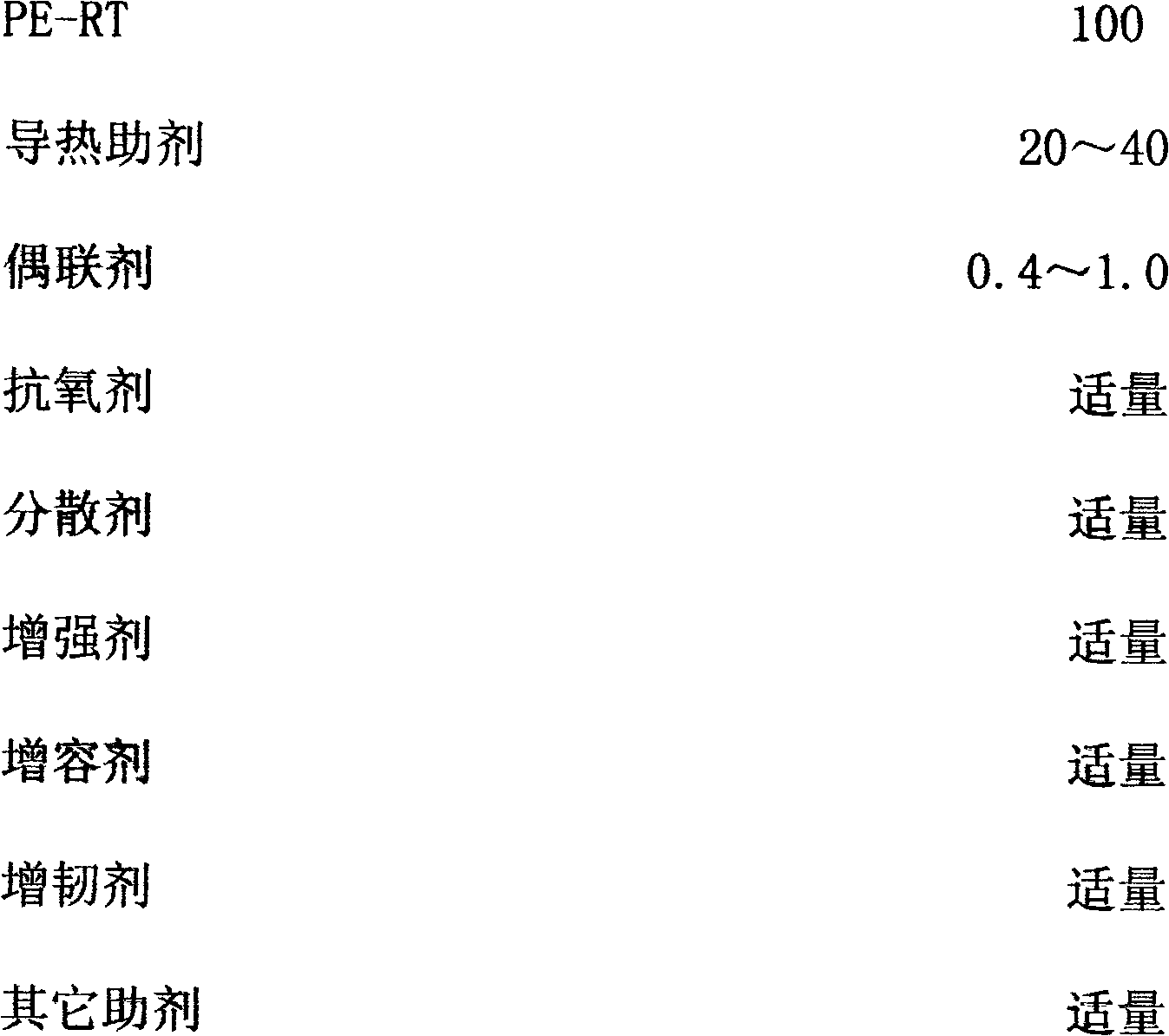

[0009] (1) Formula

[0010]

[0011] The heat conduction additive in the formula can be adjusted according to the structure and function of the pipe, such as copper fiber, aluminum fiber, stainless steel fiber, or aluminized glass fiber, silver-plated glass fiber, etc., which are prone to exposure and are not suitable for the outer surface layer of the pipe. ; Some heat-conducting materials with poor corrosion resistance are not suitable for the inner surface layer of pipes, etc.; when the material needs to be reinforced, it is advisable to add fiber-based heat-conducting materials to the formula.

[0012] (2) Use a coupling agent to activate the surface of the thermal conductivity additive

[0013] (3) After the above-mentioned components are blended, they are melted, blended, plasticized, and pelletized on a continuous internal mixer granulation unit to obtain PE-RT heat-conducting plastic pipe raw materials.

[0014] (4) According to the method of "multi-layer composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com