Method for preparing lithium ion battery anode material

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of preparation of battery positive electrode materials, can solve the problems of complicated sintering methods and unfavorable industrialized production of spinel lithium manganate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

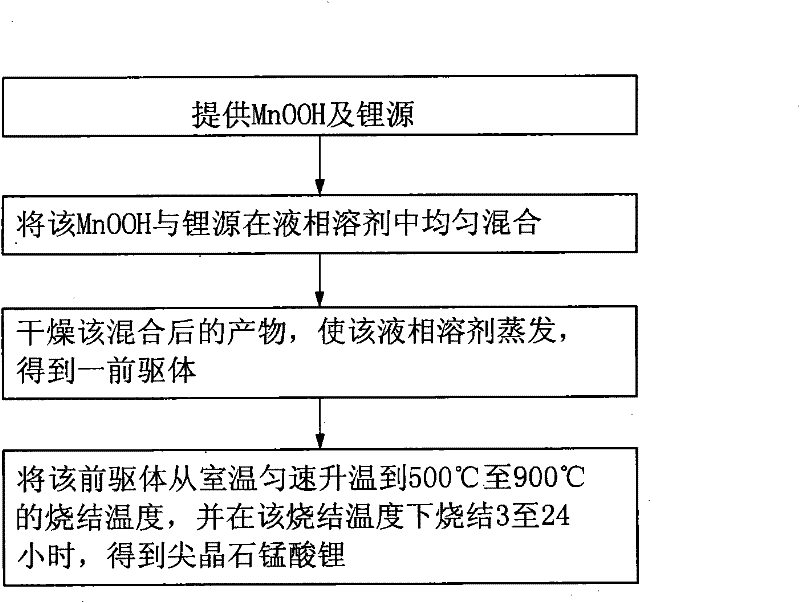

[0012] The positive electrode material and preparation method of the lithium ion battery according to the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , the embodiment of the present invention provides a kind of preparation method of lithium-ion battery cathode material, it comprises the following steps:

[0014] S1, providing MnOOH and lithium source;

[0015] S2, uniformly mixing the MnOOH and the lithium source in a liquid phase solvent;

[0016] S3, drying the mixed product, evaporating the liquid solvent to obtain a precursor; and

[0017] S4, heating the precursor from room temperature to a sintering temperature of 500° C. to 900° C. at a constant speed, and sintering at the sintering temperature for 3 to 24 hours to obtain spinel lithium manganate.

[0018] In the above step S1, the lithium source may be lithium salt, lithium hydroxide (LiOH) or a mixture of lithium salt and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com