Phase-change storage material and preparation method thereof

A technology of phase-change storage and binary materials, which is applied in the field of phase-change storage materials and its preparation, can solve the problems of non-environmental protection, low crystallization temperature, and inconvenience of follow-up processes such as microfabrication, and achieve good compatibility and simple components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a phase-change memory material, which includes an aluminum-antimony binary material whose composition formula is Al x Sb 1-x , where x is the atomic percentage of aluminum element, and 0<x<1. In the component after one or more of oxygen, nitrogen, boron, silicon and germanium are doped to the aluminum-antimony binary material, the atomic percentage of the aluminum material is between 1% and 20%.

[0028] The phase-change storage material is a material that changes reversibly under the action of external energy, and the external energy action includes electric drive, laser pulse drive or electronic drive. The aluminum-antimony binary material Al x Sb 1-x In the case of applying an electric pulse signal, a reversible switch between a high-resistance state and a low-resistance state will occur, which has the characteristics of reversible conversion between a high-resistance state and a low-resistance state, and can be used to realize data storag...

Embodiment 2

[0031] This embodiment provides a method for preparing the phase-change memory material described in Embodiment 1. The preparation method is to prepare Al by double-target magnetron co-sputtering. x Sb 1-x Thin film, specifically comprises the following steps:

[0032] 1. First prepare Al targets and Sb targets with a diameter of 75mm and a thickness of 5mm, and the purity of the targets is 99.999% (atomic percentage);

[0033] 2. Then adopt the method of double-target magnetron co-sputtering, and simultaneously feed Ar gas with a purity of 99.999% during the co-sputtering process; the specific process parameters are as follows:

[0034] 1) Al target adopts radio frequency power supply;

[0035] 2) The Sb target adopts a DC power supply, and the power of the Sb target is selected as 25W;

[0036] 3) Sputtering gas pressure is 0.26Pa.

[0037] Utilize the preparation method of the phase-change memory material described in this embodiment, can obtain the Al of different sput...

Embodiment 3

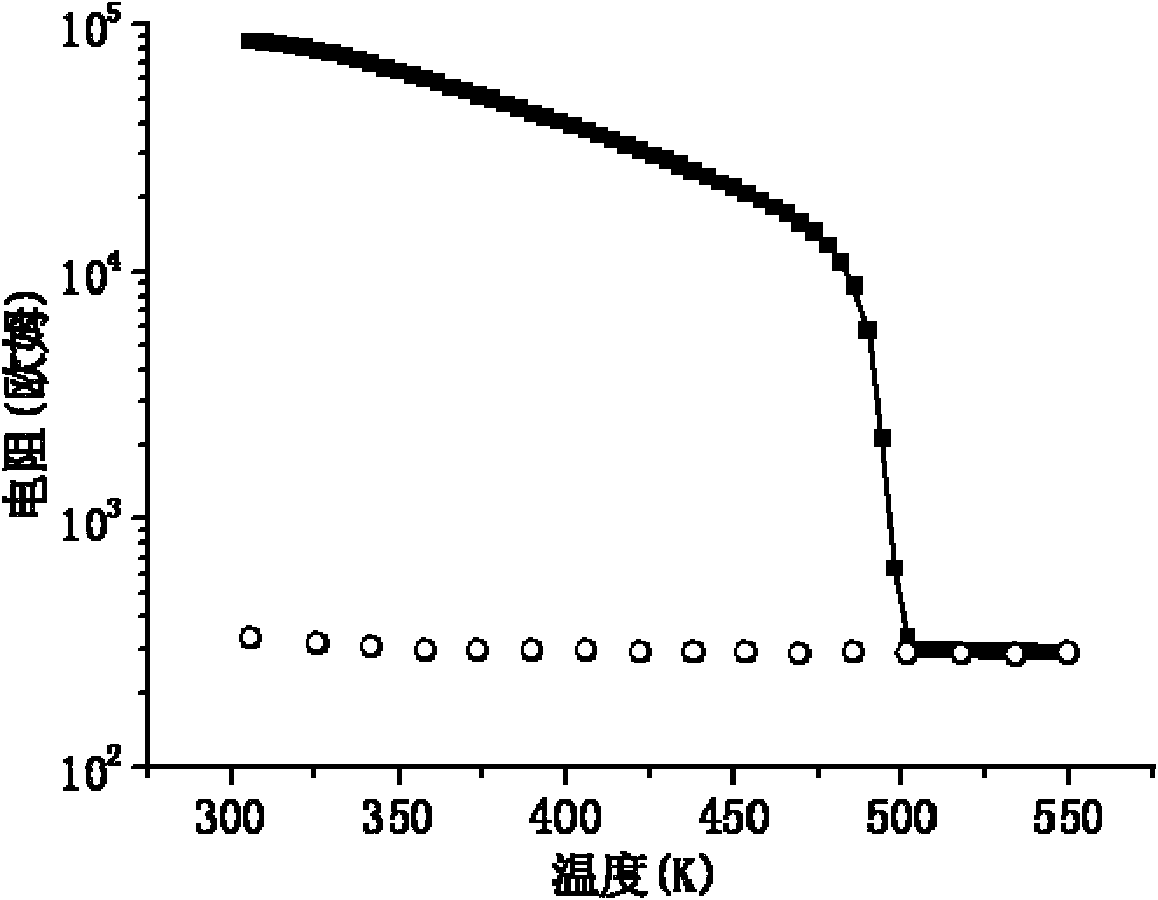

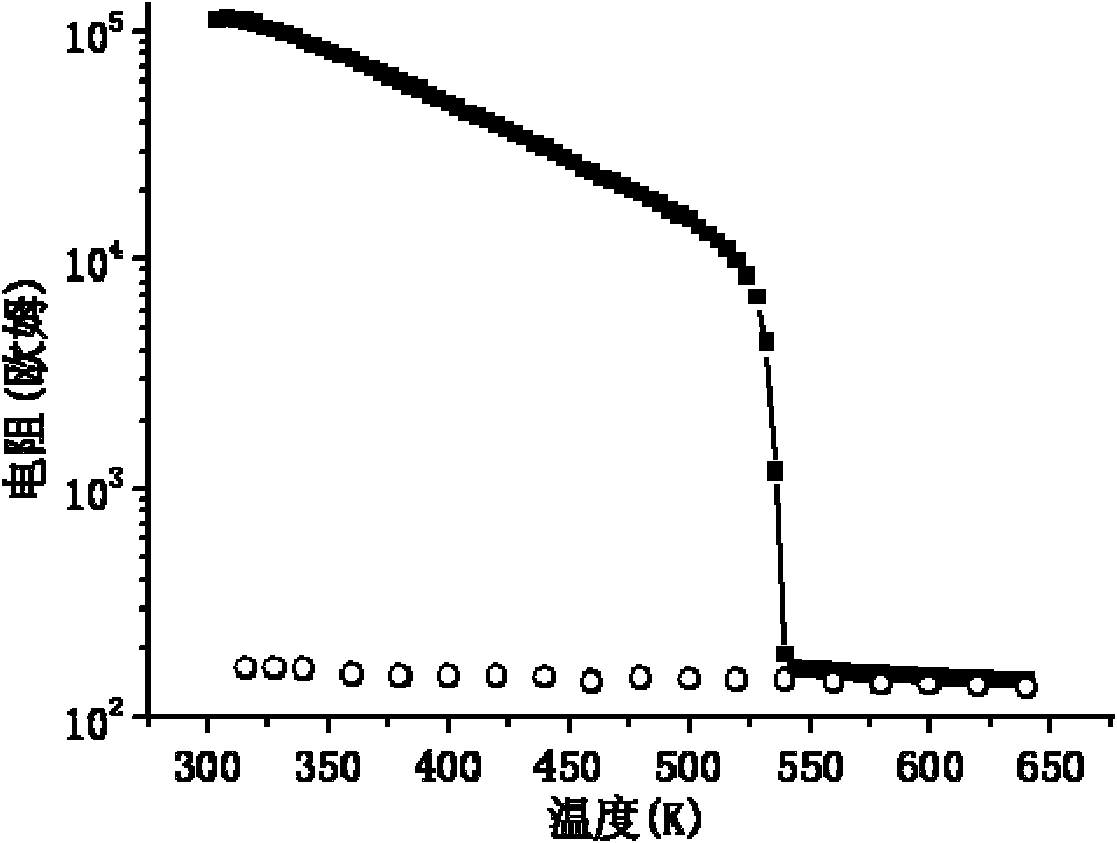

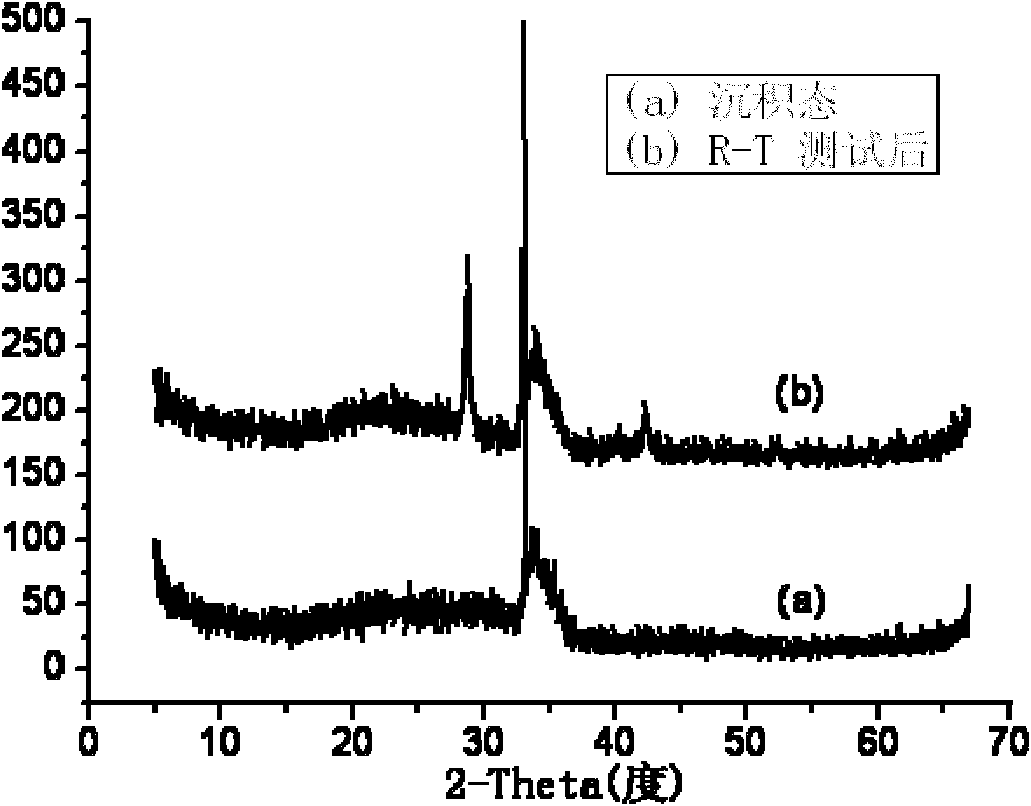

[0042] This embodiment is aimed at the two-component aluminum-antimony binary material Al0.2 Sb 0.98 and Al 0.18 Sb 0.82 Conduct temperature-resistance (R-T) test, the test results are as follows figure 1 and figure 2 shown.

[0043] figure 1 It is the curve (R-T) of the resistance of the aluminum-antimony binary material with an aluminum content of 2 atomic percent as a function of temperature (R-T), wherein the solid curve is the heating process, and the hollow curve is the cooling process. Depend on figure 1 It can be seen that when the aluminum content in the alloy material is 2 atomic percent, the resistance of the material decreases as the temperature rises, and drops sharply when the temperature is around 480K. The R-T test shows that the aluminum-antimony binary material Al 0.2 Sb 0.98 The crystallization temperature is about 480K, and the difference between high and low resistivity reaches two orders of magnitude.

[0044] figure 2 It is the curve (R-T) of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com