Phase-change storage material and preparation method thereof

A technology of phase change storage and radio frequency power, which is applied in the field of phase change storage materials and its preparation, can solve the problems of low crystallization temperature, non-environmental protection, restrictions, etc., and achieve the effect of simple components and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a phase-change memory material, which includes an aluminum-antimony binary material whose composition formula is Al x Sb 1-x , where x is the atomic percentage of aluminum element, and 0<x<1. In the component after one or more of oxygen, nitrogen, boron, silicon and germanium are doped to the aluminum-antimony binary material, the atomic percentage of the aluminum material is between 1% and 20%.

[0028] The phase-change storage material is a material that changes reversibly under the action of external energy, and the external energy action includes electric drive, laser pulse drive or electronic drive. The aluminum-antimony binary material Al x Sb 1-x In the case of applying an electric pulse signal, a reversible switch between a high-resistance state and a low-resistance state will occur, which has the characteristics of reversible conversion between a high-resistance state and a low-resistance state, and can be used to realize data storag...

Embodiment 2

[0031] This embodiment provides a method for preparing the phase-change memory material described in Embodiment 1. The preparation method is to prepare Al by double-target magnetron co-sputtering. x Sb 1-x Thin film, specifically comprises the following steps:

[0032] 1. First prepare Al targets and Sb targets with a diameter of 75mm and a thickness of 5mm, and the purity of the targets is 99.999% (atomic percentage);

[0033] 2. Then adopt the method of double-target magnetron co-sputtering, and simultaneously feed Ar gas with a purity of 99.999% during the co-sputtering process; the specific process parameters are as follows:

[0034] 1) Al target adopts radio frequency power supply;

[0035] 2) The Sb target adopts a DC power supply, and the power of the Sb target is selected as 25W;

[0036] 3) Sputtering gas pressure is 0.26Pa.

[0037] Utilize the preparation method of the phase-change memory material described in this embodiment, can obtain the Al of different sput...

Embodiment 3

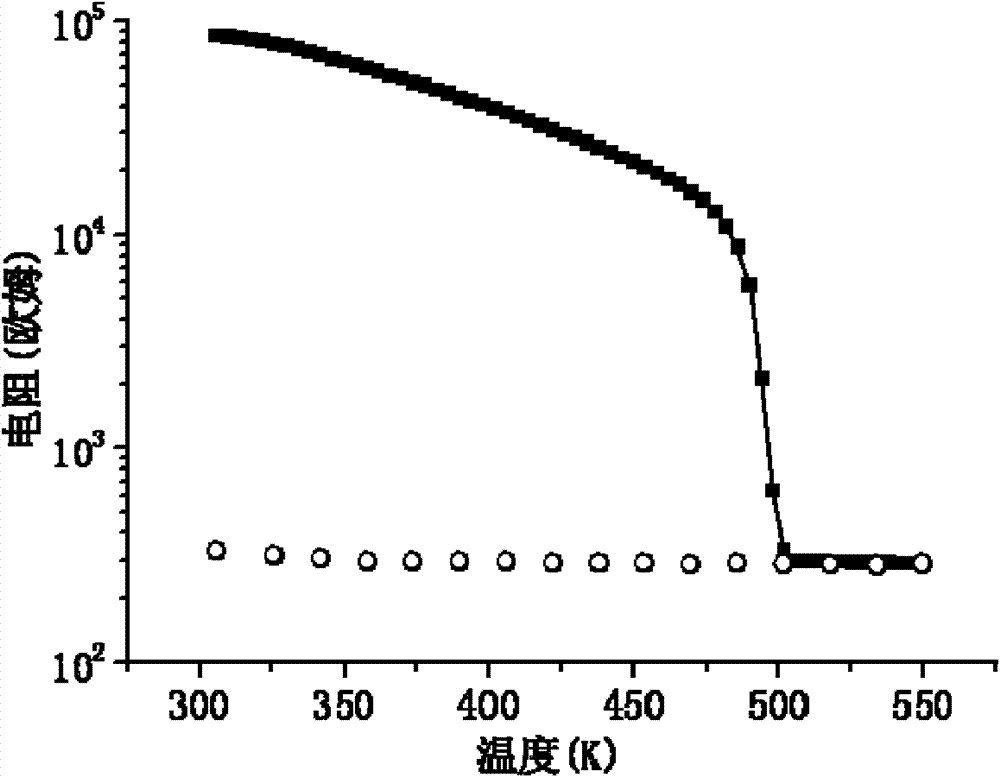

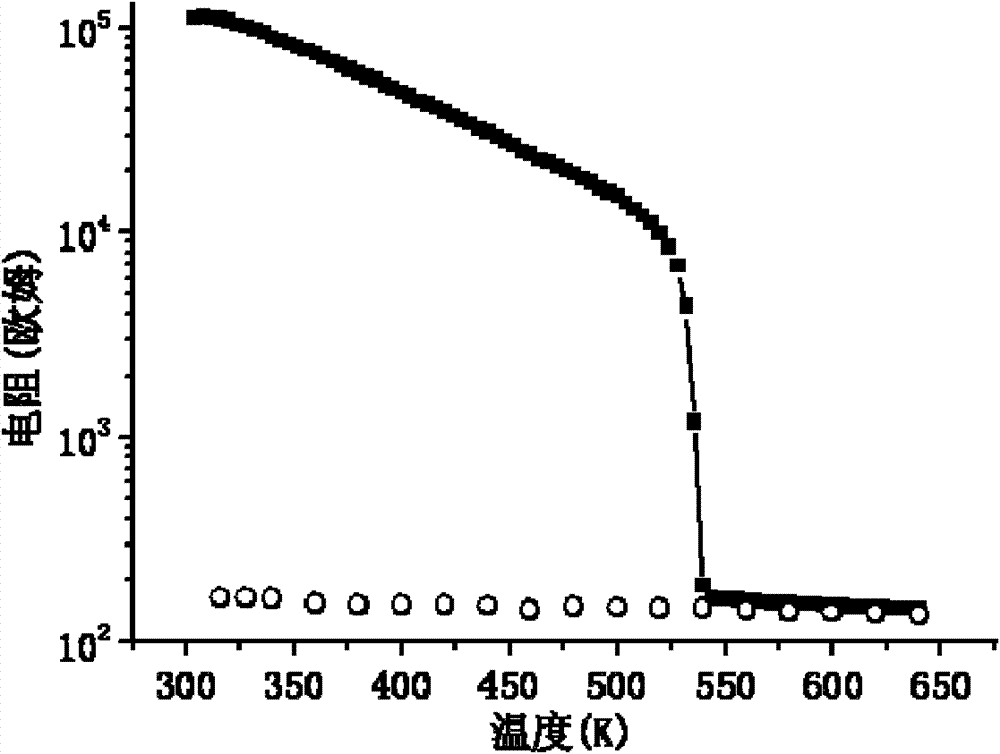

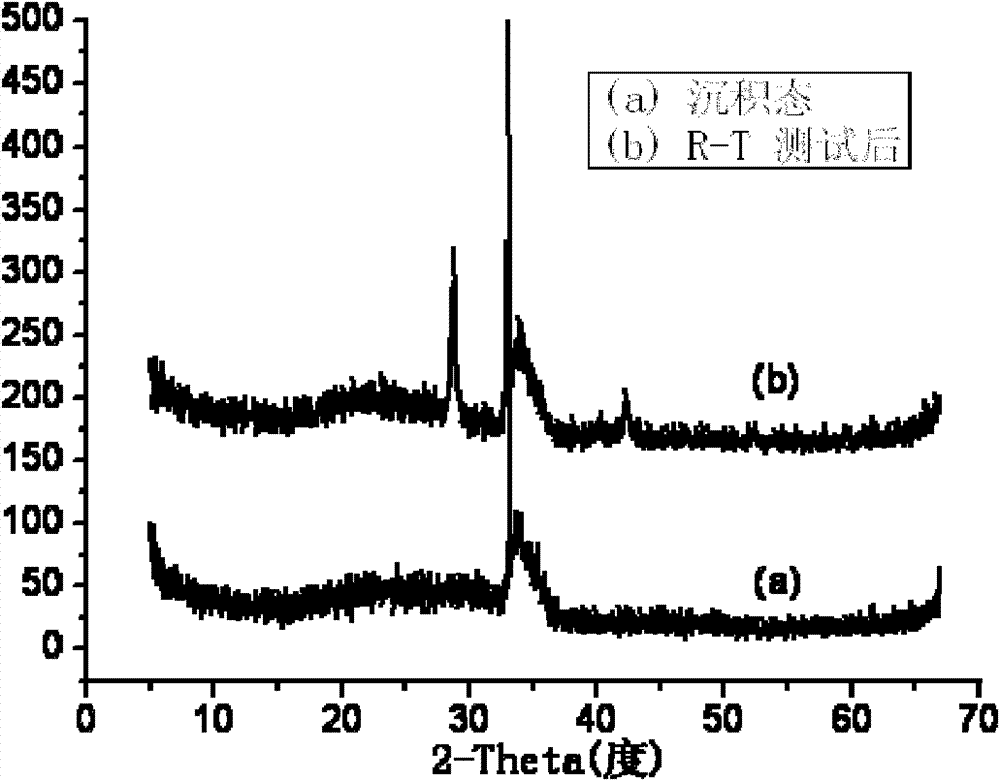

[0042] This embodiment is aimed at the two-component aluminum-antimony binary material Al0.2 Sb 0.98 and Al 0.18 Sb 0.82 Conduct temperature-resistance (R-T) test, the test results are as follows figure 1 and figure 2 shown.

[0043] figure 1 It is the curve (R-T) of the resistance of the aluminum-antimony binary material with an aluminum content of 2 atomic percent as a function of temperature (R-T), wherein the solid curve is the heating process, and the hollow curve is the cooling process. Depend on figure 1 It can be seen that when the aluminum content in the alloy material is 2 atomic percent, the resistance of the material decreases as the temperature rises, and drops sharply when the temperature is around 480K. The R-T test shows that the aluminum-antimony binary material Al 0.2 Sb 0.98 The crystallization temperature is about 480K, and the difference between high and low resistivity reaches two orders of magnitude.

[0044] figure 2 It is the curve (R-T) of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com