Method for preparing lysosomal collagen

A collagen and soluble technology, which is applied in the field of preparation of enzyme-soluble collagen, can solve the problems of high cost, poor thermal stability of enzyme-soluble collagen, complex preparation process, etc., and achieve low production cost, simple and reasonable method, and high yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

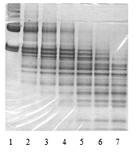

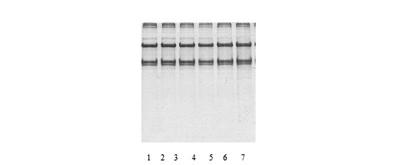

Image

Examples

Embodiment 1

[0020] Example 1. A preparation method of enzyme-soluble collagen, the steps are as follows:

[0021] (1) Raw material treatment: use fish skin or other animal tissues as raw materials, wash with water, soak in 0.05mol / L NaOH solution at 0°C for 1 hour, during the soaking process, change the soaking solution every 1 hour, Raw materials for removing miscellaneous proteins; then soaking in detergent or organic solvent for 1 hour, and then washing with water at 0°C to obtain raw materials for removing fat;

[0022] (2) Collagen extraction: add 0.05mol / L acetic acid, citric acid or hydrochloric acid solution to the processed raw materials as extractant for extraction for 2 hours, the extraction temperature is 0°C, and add 0.05% of the weight of raw materials at the same time Protease, the weight ratio of raw material and extractant is 1:5, after leaching and filtering, the obtained filtrate is enzyme-soluble collagen crude extract;

[0023] (3) Collagen purification and inactiva...

Embodiment 2

[0024] Example 2. A preparation method of enzyme-soluble collagen, the steps are as follows:

[0025] (1) Raw material treatment: use fish skin or other animal tissues as raw materials, wash with water, soak in 5.0mol / L NaOH solution at 40°C for 50 hours, during the soaking process, change the soaking solution every 5 hours, Raw materials for removing miscellaneous proteins; then soaked in detergent or organic solvent for 50 hours, and then washed with water at 30°C to remove raw materials for fat;

[0026] (2) Collagen extraction: add 10mol / L acetic acid, citric acid or hydrochloric acid solution to the treated raw materials as extractant for extraction for 72 hours, the extraction temperature is 40°C, and add 10% pepsin by weight of raw materials at the same time , the weight ratio of the raw material to the extractant is 1: 100, filtered after leaching, and the obtained filtrate is the crude enzyme-soluble collagen extract;

[0027] (3) Collagen purification and inactivat...

Embodiment 3

[0028] Example 3. A preparation method of enzyme-soluble collagen, the steps are as follows:

[0029] (1) Raw material treatment: use fish skin or other animal tissues as raw materials, wash with water, soak in 0.5mol / L NaOH solution at 4°C for 20 hours, during the soaking process, change the soaking solution every 3 hours, The raw material for removing miscellaneous protein; then soak in detergent or organic solvent for 20 hours, and then wash with water at 2°C to get the raw material for removing fat;

[0030] (2) Collagen extraction: add 0.1mol / L acetic acid, citric acid or hydrochloric acid solution to the processed raw materials as extractant for extraction for 48 hours, the extraction temperature is 3°C, and add 0.5% of raw material weight stomach Protease, the weight ratio of raw material and extractant is 1:20, after leaching and filtering, the filtrate obtained is the crude enzyme-soluble collagen extract;

[0031] (3) Collagen purification and inactivation of enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com