Room temperature self-repair thermoplastic polymer material

A thermoplastic polymer self-healing technology, applied in the field of room temperature self-healing thermoplastic polymer materials, can solve the problems of weak repair strength and limited thermoplastic self-healing technology, and achieve the goals of increasing bonding capacity, simplifying preparation, and high repairing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

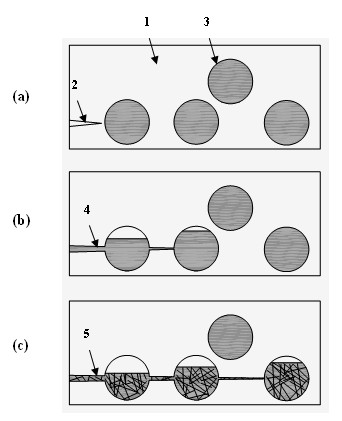

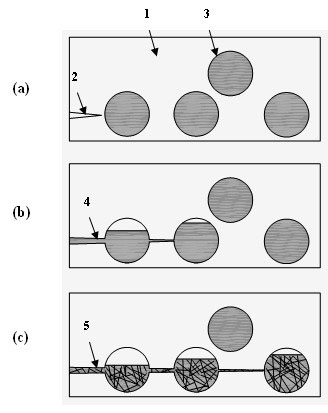

Method used

Image

Examples

Embodiment 1

[0028] Preparation of microcapsules containing liquid vinyl monomers: 11.36 g of melamine and 24.3 g of 37% (weight ratio) formaldehyde solution and 30 ml of distilled water were added to a three-necked reaction flask at 60 to 70 ° C and a pH value of 8 to 9. After 20-30 minutes of reaction, a transparent melamine-formaldehyde prepolymer solution is obtained. Add 0.4 g of sodium dodecylbenzenesulfonate, 0.12 g of polyvinyl alcohol and 41 g of glycidyl methacrylate, and emulsify for 30 minutes at a rotation speed of 400 rpm. Slowly adjust the pH value of the reaction system to about 4.1 with 5% glacial acetic acid, and slowly raise the temperature to 65 o C, maintaining the reaction temperature for 3 hours. The reaction solution was cooled to room temperature, washed with water to leave a layer of product, filtered, and dried at room temperature to obtain a white microcapsule product with good fluidity. The average particle size of the synthesized microcapsules was analyzed t...

Embodiment 2

[0030] Add 25.0 g of methyl methacrylate, 0.119 g of cumyl dithiophenylacetate, and 0.068 g of azobisisobutyronitrile into a three-necked flask to fully dissolve them, and feed argon to maintain the reaction system as an inert atmosphere. at 45 o React at 24 hours at C, weigh 0.625 g of microcapsules loaded with glycidyl methacrylate prepared in Example 1, uniformly disperse in the above-mentioned polymethyl methacrylate prepolymer at room temperature, mix and degas Pour into a silicone mold and cure at room temperature for 96 hours under an argon atmosphere.

[0031] The cantilever beam impact specimen was used to conduct the fracture test and evaluate the repair efficiency of the material: the specimen was put into the 25 o Keep the temperature in a constant temperature oven at C for 2 hours, and then completely destroy it with the help of an impact instrument. Carefully align the fractured surface of the damaged sample, clamp the sample in a repair fixture, and quickly put...

Embodiment 3

[0034] Add 25.0 g of methyl methacrylate, 0.119 g of cumyl dithiophenylacetate, and 0.068 g of azobisisobutyronitrile into a three-necked flask to fully dissolve them, and feed argon to maintain the reaction system as an inert atmosphere. at 45 o React at 24 hours at C, weigh 1.25 g of microcapsules loaded with glycidyl methacrylate prepared in Example 1, and uniformly disperse them in the above-mentioned polymethyl methacrylate prepolymer at room temperature, after mixing and degassing Pour into a silicone mold and cure at room temperature for 96 hours under an argon atmosphere.

[0035] The evaluation method is the same as in Example 2. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com