Method for preparing electrode silver paste for environment-friendly semiconductor capacitor

A technology for semiconductors and capacitors, which is applied in the field of preparation of electrode silver paste for semiconductor capacitors. It can solve the problems that lead-containing silver paste cannot meet the needs of the industry, and achieve the effects of high capacitance, adhesion, solder resistance, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

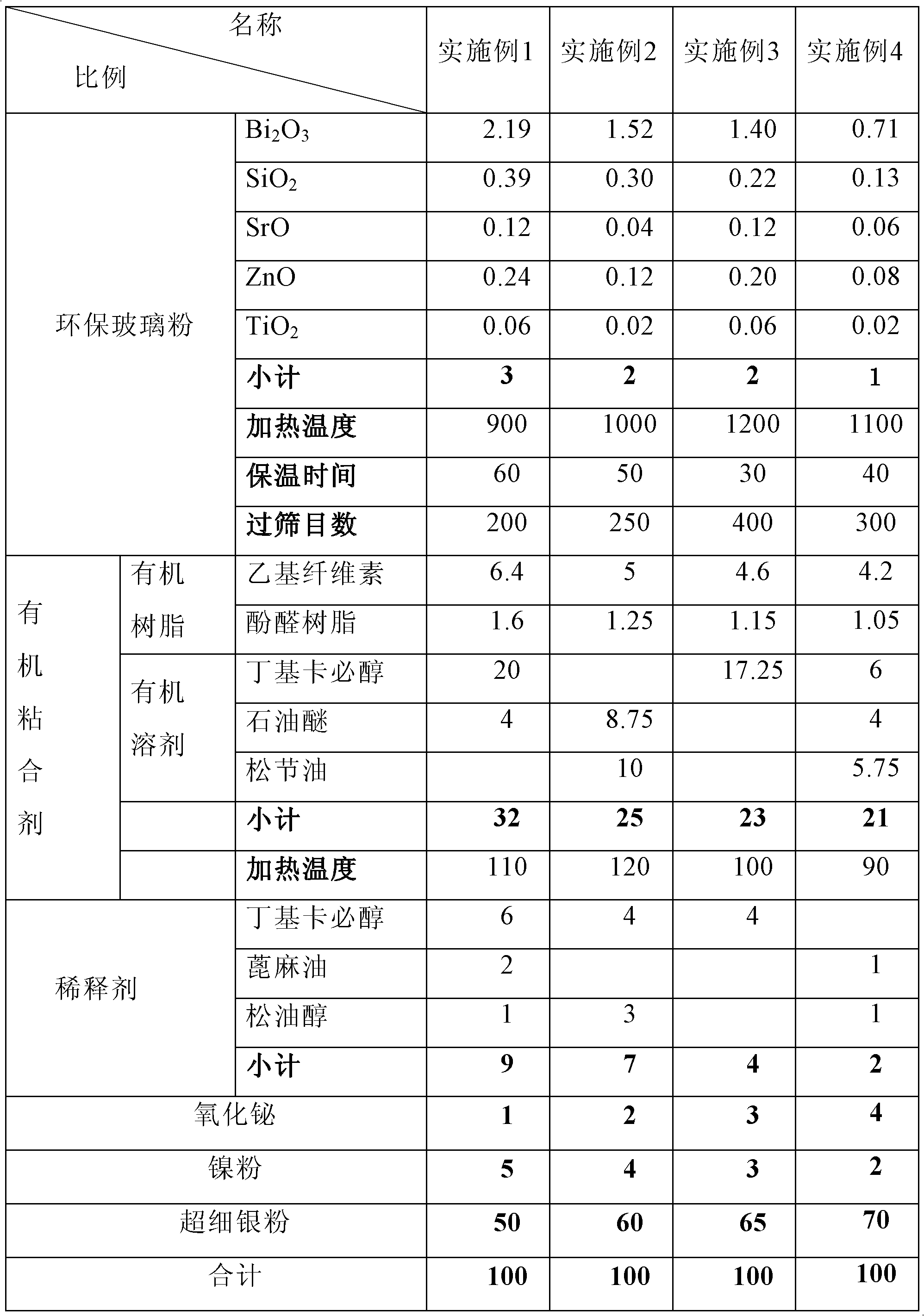

[0019] The present invention will be further described below through specific examples.

[0020] The preparation method of electrode silver paste for environment-friendly semiconductor capacitor of the present invention comprises the following basic steps:

[0021] Step A: Preparation of environmentally friendly glass powder

[0022] Weigh according to the raw material composition and mass percentage of environmentally friendly glass powder:

[0023] Bi 2 o 3 70-76%; SiO 2 11-15%; SrO 2-6%; ZnO 6-10%; TiO 2 1-3%;

[0024] Mix the above-mentioned raw materials that have been weighed evenly and heat them in a high-temperature furnace. The temperature control range is 900-1200 ° C, and the holding time is 30-60 minutes. After the melted glass powder particles are quenched with deionized water, they are ball-milled to 0.5 -2um, sieved with 200-400 mesh, dried for later use; the glass powder with SrO and TiO2 added and the substrate of the capacitor are more likely to eute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com