Permanent magnet synchronous motor drive control system

A permanent magnet synchronous motor, drive control technology, applied in the control system, vector control system, motor generator control, etc., can solve the problem that the motor parameters are easily affected by the outside world, cannot meet the high real-time requirements of the servo system, high real-time The current loop control is difficult to meet and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

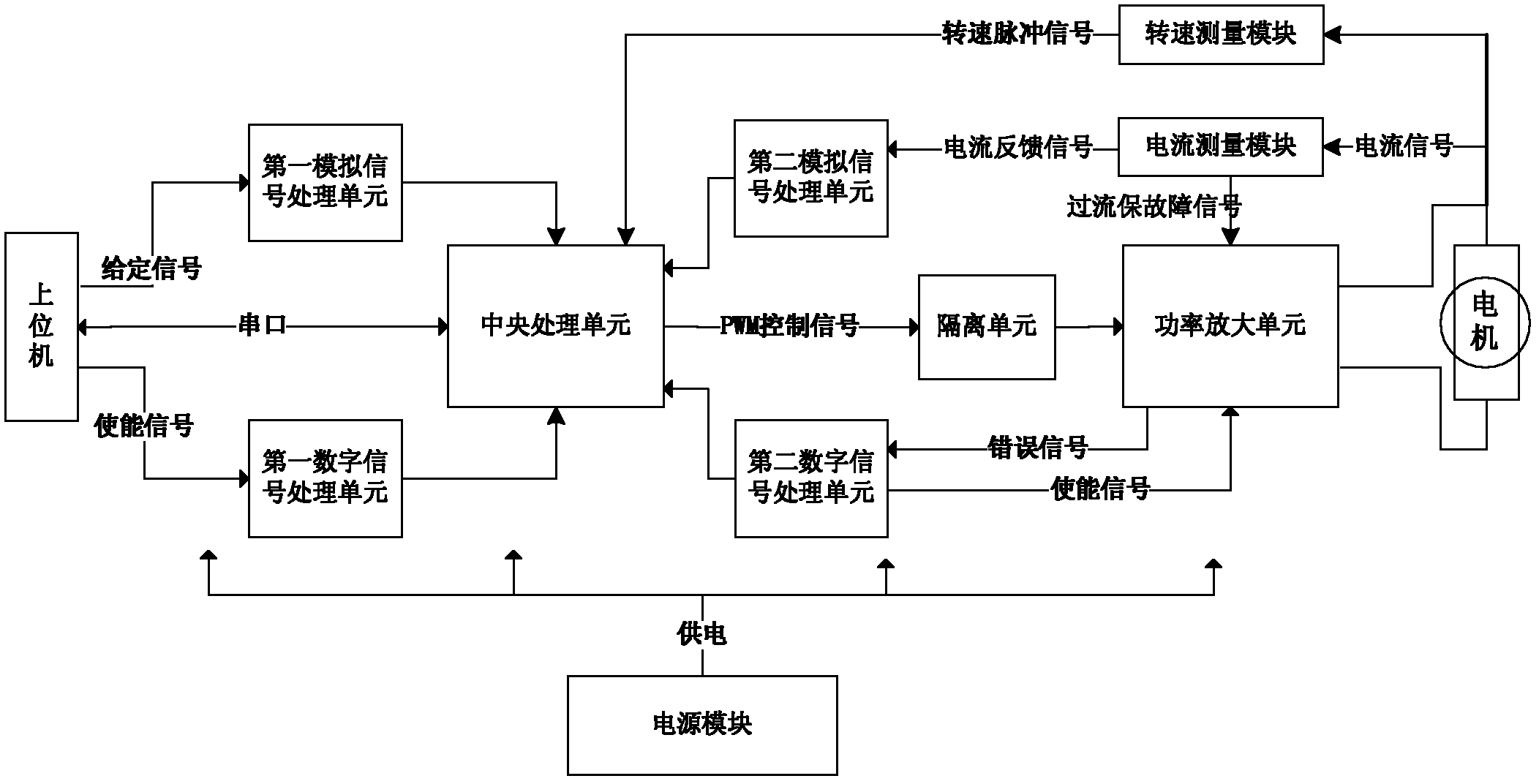

[0065] A permanent magnet synchronous motor drive control system, the peripheral equipment of which is a controlled motor and a host computer, consisting of a power supply module, a central control unit, 2 analog signal processing units, 2 digital signal processing units, a current measurement module, and a rotational speed measurement module , an isolation unit and a power amplifier unit;

[0066] The above power module adopts isolated power supply and is responsible for providing power to other departments;

[0067] The main control chip of the above-mentioned central control unit adopts the DSP chip of TI Company, the model is TMS320F2812;

[0068] The above isolation unit uses a high-speed optocoupler to achieve isolation, and the model of the high-speed optocoupler is 6N137;

[0069] The driving chip of the inverter bridge switching tube driving circuit in the above power amplification unit is IR2136;

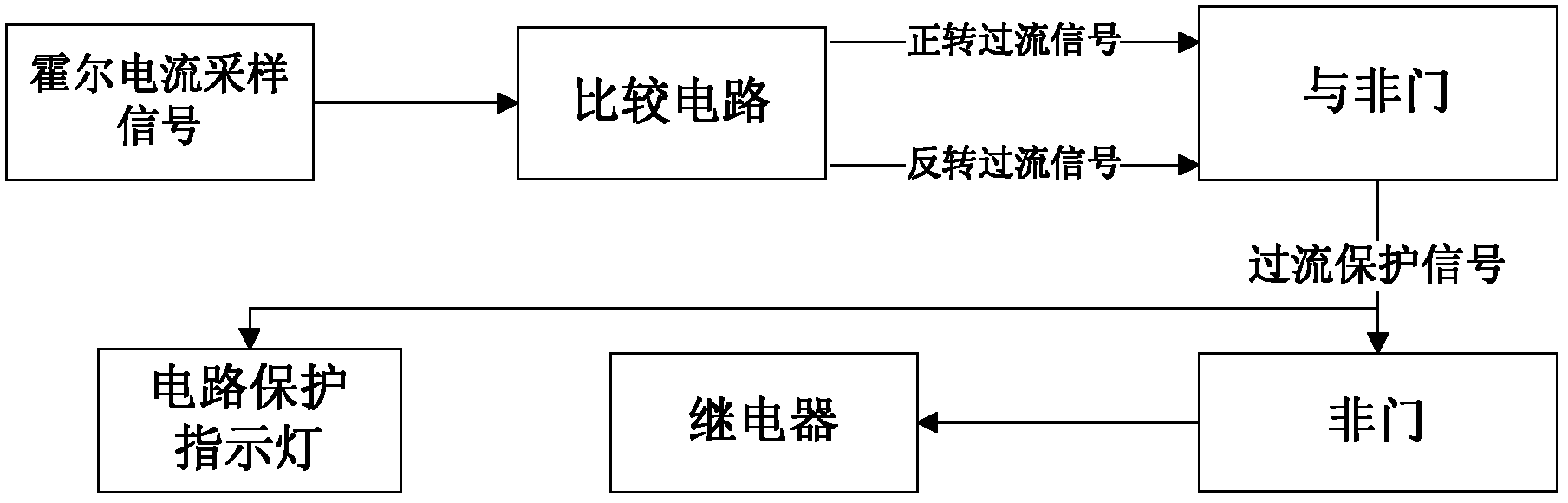

[0070] The functional block diagram of the above-mentioned overcurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com