Production method for desalination and comprehensive utilization of seawater

A production method, concentrated seawater technology, applied in chemical instruments and methods, seawater treatment, magnesium hydroxide, etc., can solve the problems of large climate impact, passive production, and many impurities and salts, and achieve the effect of solving discharge pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

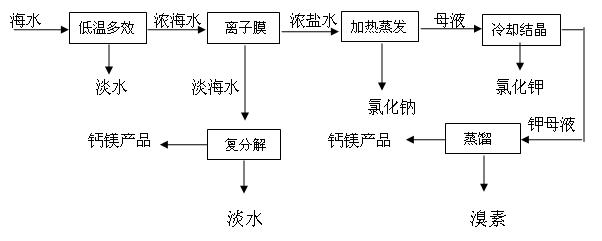

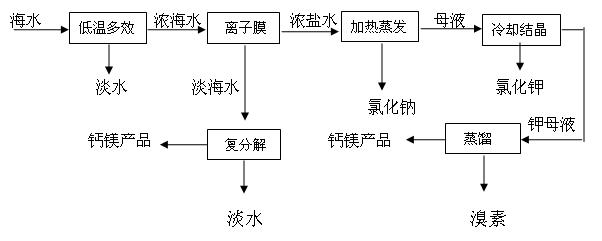

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] a. Concentrate the concentrated seawater with a concentration of 4-6 〇 Be', when the temperature is above 20 ℃, permeates through the ionic membrane, separates the 1-valent ions from the 2-valent ions, and obtains concentrated seawater containing sodium chloride, potassium chloride and a small amount of calcium and magnesium salts and magnesium sulfate, calcium sulfate 2-valent Salt fresh sea water, stored separately;

[0017] b. Mix the concentrated seawater obtained in the above steps with a concentration of 20 〇 Above Be', heating to 100°C-120°C, sodium chloride is precipitated, solid-liquid separation, solid phase is washed and dehydrated to become sodium chloride product, liquid phase is cooled and crystallized by cooling equipment, and potassium chloride product is produced;

[0018] c. the mother liquor obtained after making potassium in the step b is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com