Antiseptic processing method for capping part of brick lining chimney

A technology of anti-corrosion treatment and chimney, which is applied in the field of anti-corrosion treatment of brick-lined chimneys, and can solve the problems of chimney anti-corrosion failure, anti-corrosion failure, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

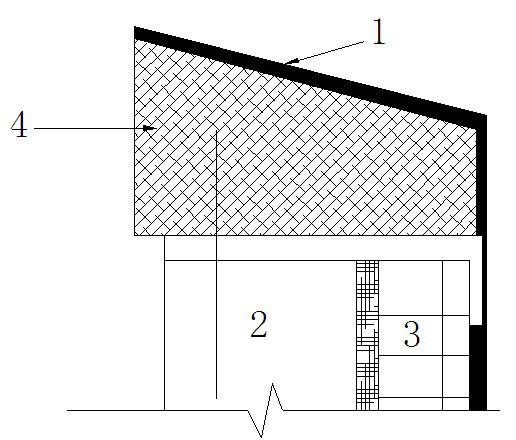

[0022] Embodiment 1, brick chimney concrete pressure top anti-corrosion treatment, as figure 2 As shown in the figure, 1 is the VP3-2 layer of polyfluorine organic lining anticorrosion material, 2 is the concrete outer wall of the chimney, 3 is the inner lining of the chimney, and 4 is the concrete topping.

[0023] (1) While washing the inner wall of the overall chimney with high-pressure water, also wash the area of the top concrete top 4 with high-pressure water to remove impurities such as loose layers and floating ash at the top of the chimney;

[0024] (2) Use the repairing material potassium silicate cement to repair or partially level the gaps in the top concrete bricks, and the drying time is not less than 48 hours;

[0025] (3) Spray, scrape, brush or roll coat VP3-2 layer 1 of polyfluorinated organic lining anti-corrosion material on the concrete top surface, with a thickness of 1±0.2mm;

[0026] (4) Curing: Room temperature: 1-3 days, or heating: after curing a...

Embodiment 2

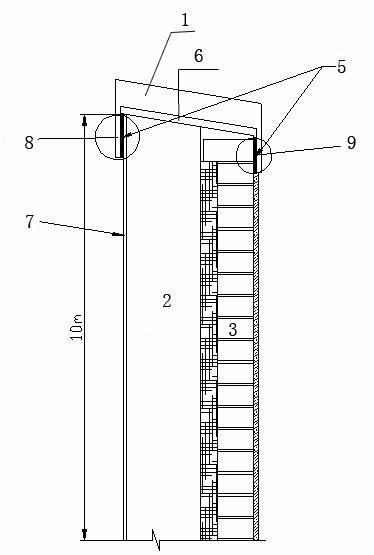

[0027] Embodiment 2, brick chimney cast iron pressure top anticorrosion treatment, as image 3 As shown in the figure, 1-polyfluorine organic lining anti-corrosion material VP3-2 layer, 2 is the chimney concrete outer wall, 3 is the chimney inner lining, 5-silicone rubber high temperature elastic bonding sealing material, 6-cast iron pressure top, 7 -Chlorinated rubber paint layer, 8-joint joint between cast iron roof and outer wall, 9-joint joint between cast iron roof and inner wall.

[0028] (1) Rinse the entire cast iron roof 23 with high-pressure water, and manually remove the mortar and acid-resistant mortar in the joint 8 of the cast iron roof and the outer wall and the joint 9 of the cast iron roof and the inner wall to remove impurities in the joint;

[0029] (2) Fill the joint 8 of the cast iron top and the outer wall and the joint 9 of the cast iron top and the inner wall into the silicone rubber high temperature elastic bonding sealing material 5; and brush the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com