Solid basic catalyst and preparation method and application thereof

A solid base catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost, low biodiesel production efficiency, and product processing. complex problems, to achieve the effect of fast heating rate, sensitive temperature program control, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

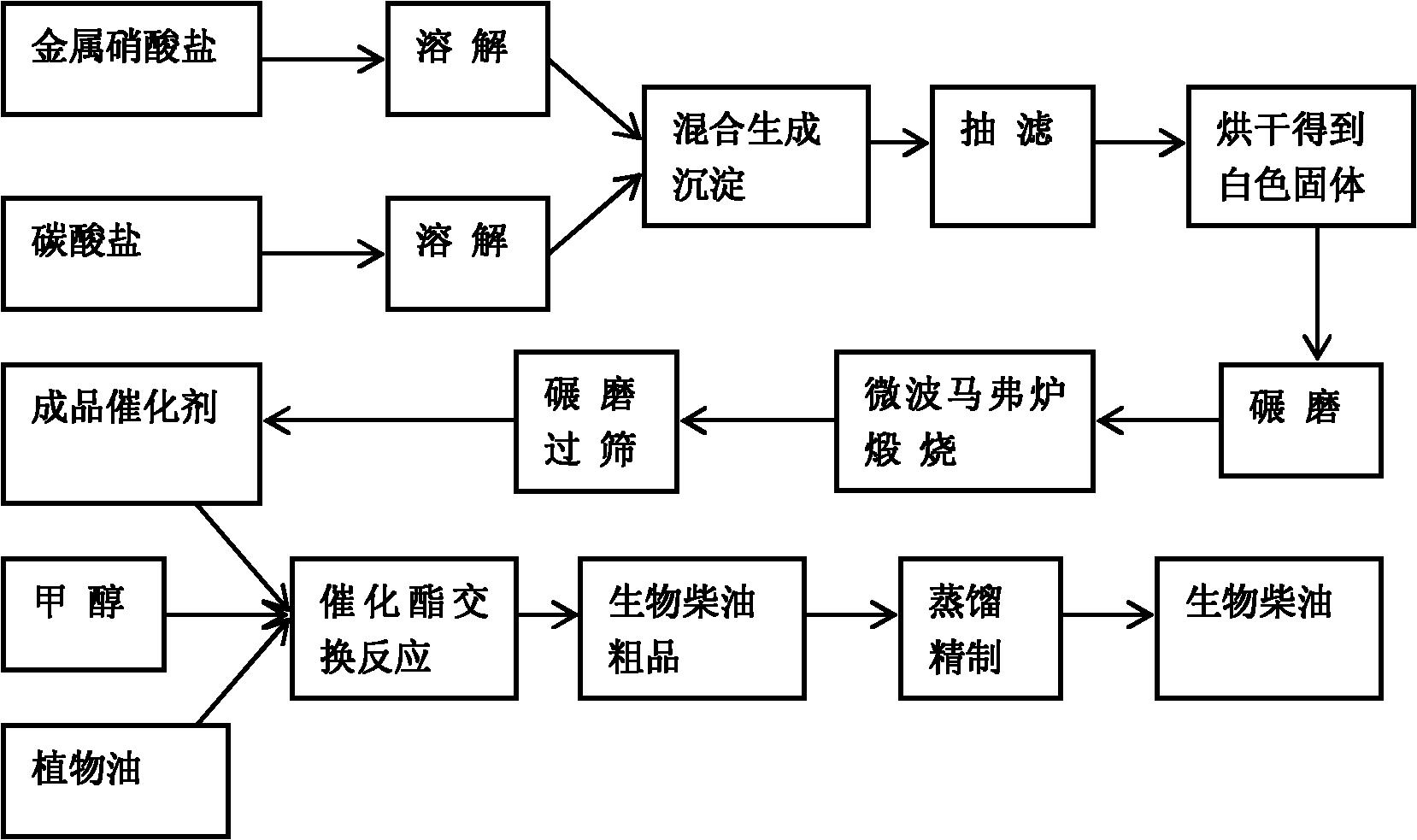

[0047] Embodiment 1: the preparation method of solid catalyst

[0048] 1. Preparation method

[0049] 1) Calcium nitrate, magnesium nitrate and zinc nitrate are mixed in a mass ratio of 1.0: 1.8: 2.3, dissolved in 500ml of distilled water to obtain a nitrate mixed solution;

[0050] 2) Dissolve ammonium carbonate in 500ml of distilled water to obtain a 1mol / l carbonate solution;

[0051] 3) while rapidly stirring the nitrate solution, slowly add the carbonate solution, control the pH value of the solution to 7, and react for 3 hours to form a precipitate;

[0052] 4) Suction filter the obtained precipitate, wash with hot water, and dry at 60° C. for 10 h. The solid base catalyst was obtained by grinding the dried product into a white powder and calcining it in a microwave muffle furnace at 1000° C. for 5 hours.

[0053] 2. The yield of the solid base catalyst is 26.2%.

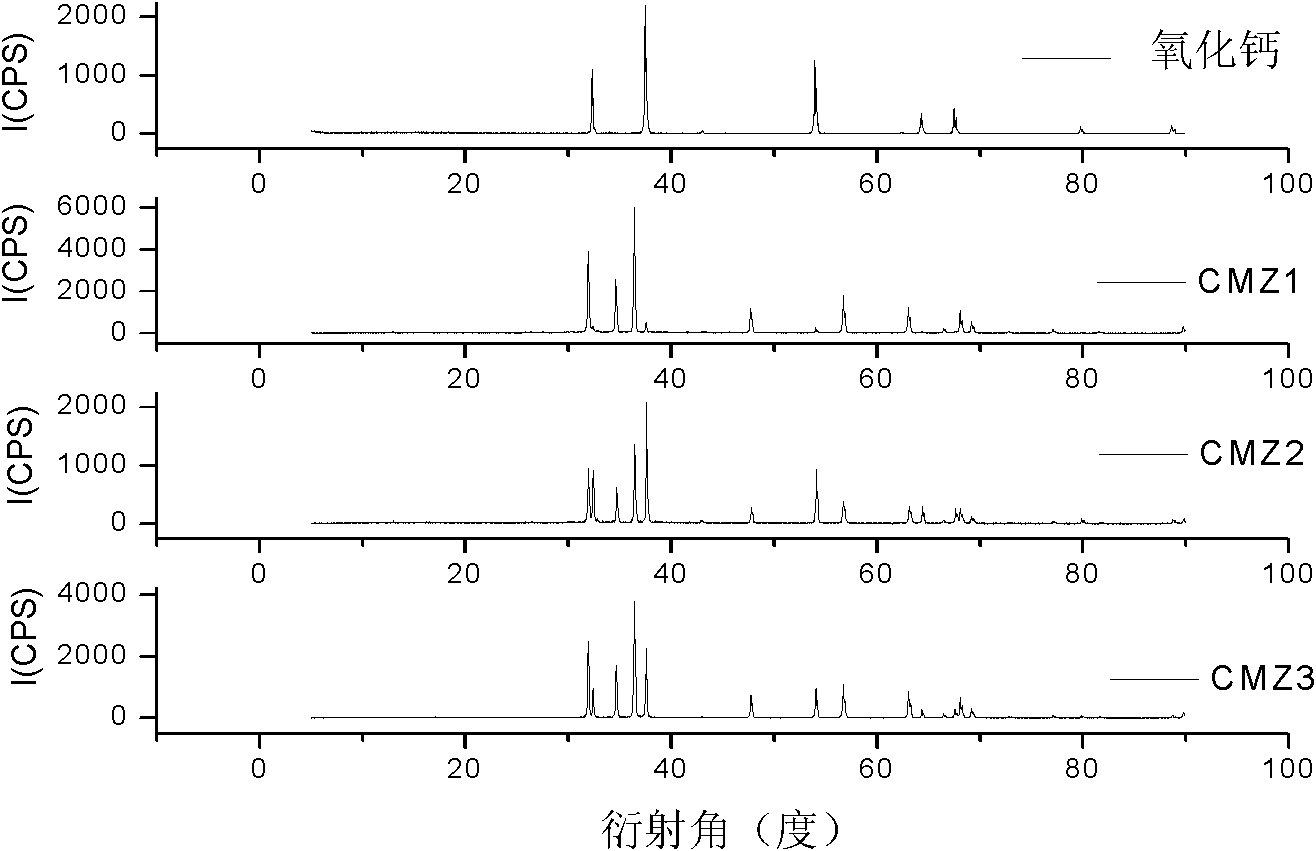

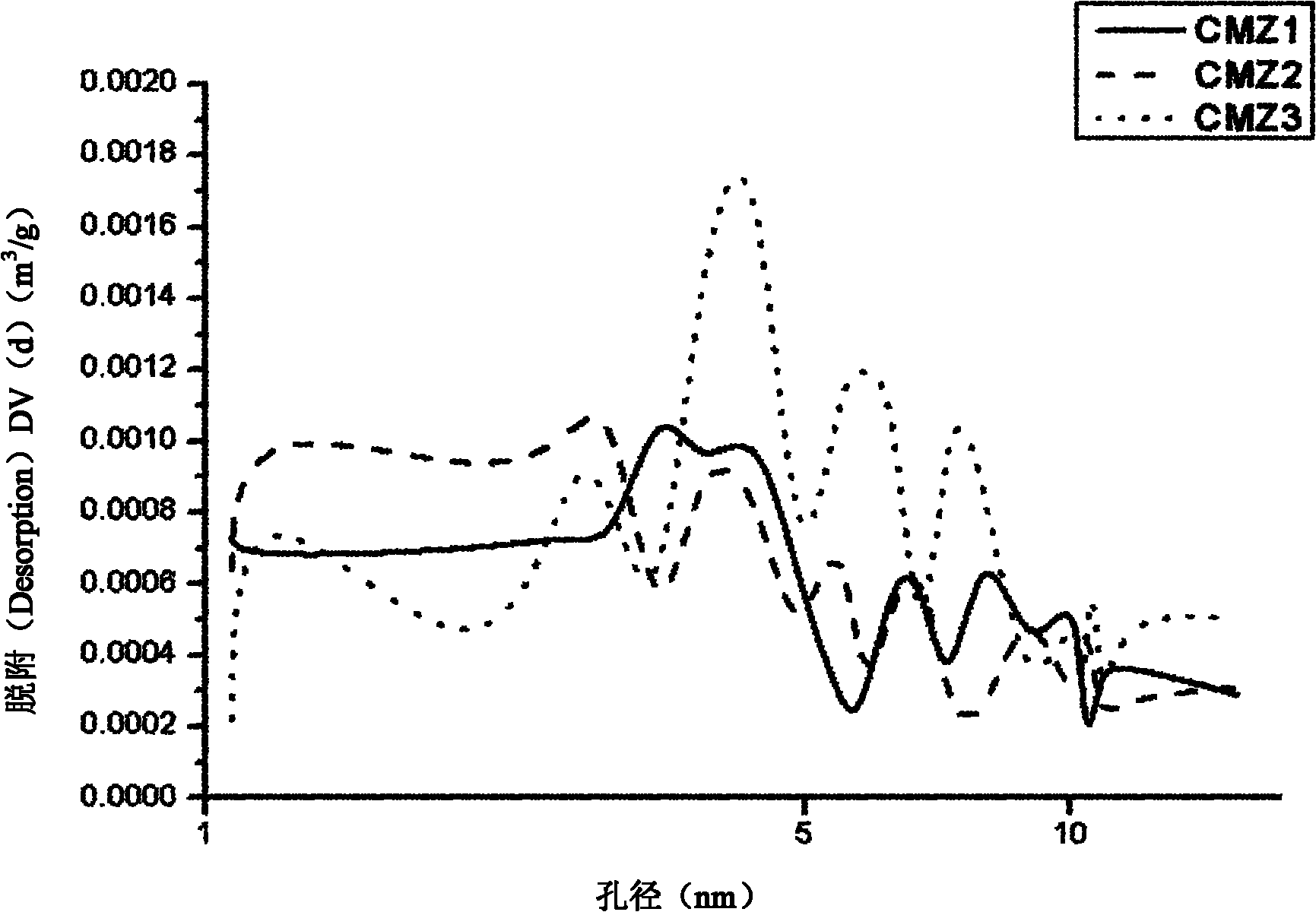

[0054] 3. The mass ratio of calcium oxide, magnesium oxide and zinc oxide in the solid base catalyst is 1...

Embodiment 2

[0055] Embodiment 2: the preparation method of solid base catalyst

[0056] 1. Preparation method

[0057] 1) Calcium nitrate, magnesium nitrate and zinc nitrate are mixed in a mass ratio of 2.2: 1.0: 8.9 and dissolved in 500ml of distilled water to obtain a nitrate mixed solution;

[0058] 2) Dissolve sodium carbonate in 500ml of distilled water to obtain a 1mol / l carbonate solution;

[0059] 3) while rapidly stirring the nitrate solution, slowly add the carbonate solution, control the pH value of the solution to 6.5, and react for 4 hours to form a precipitate;

[0060] 4) Suction filter the obtained precipitate, wash with hot water, and dry at 110°C for 1 hour;

[0061] 5) Grinding the dried material to obtain a white powder, and calcining the white powder in a microwave muffle furnace at 800° C. for 2 hours to obtain the solid base catalyst.

[0062] 2. The yield of the solid base catalyst is 36.1%.

[0063] 3. The mass ratio of calcium oxide, magnesium oxide and zinc ...

Embodiment 3

[0064] Embodiment 3: the preparation method of solid base catalyst

[0065] 1. Preparation method:

[0066] 1) Calcium nitrate, magnesium nitrate and zinc nitrate are mixed in a mass ratio of 2.2:7.2:1.3 and dissolved in 500ml of distilled water to obtain a nitrate mixed solution;

[0067] 2) Potassium carbonate was dissolved in 500ml of distilled water to obtain a 1mol / l carbonate solution;

[0068] 3) while rapidly stirring the nitrate solution, slowly add the carbonate solution, control the pH value of the solution to 7.5, and react for 4 hours to form a precipitate;

[0069] 4) Suction filter the obtained precipitate, wash with hot water, and dry at 110°C for 4 hours;

[0070] 5) Grinding the dried material into a white powder, and putting the white powder into a microwave muffle furnace for calcination at 700° C. for 3 hours to obtain the solid base catalyst.

[0071] 2. The yield of the solid base catalyst is 27.5%.

[0072] 3. The mass ratio of calcium oxide, magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com