Compound functional sandwich glass containing metal nano-structured conductive layer

A metal nanostructure and laminated glass technology, applied in the direction of metal layered products, windshields, glass/slag layered products, etc., can solve the problem of affecting the service life of the automotive glass power supply system, potential safety hazards in vehicle use, and voltage conversion Loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

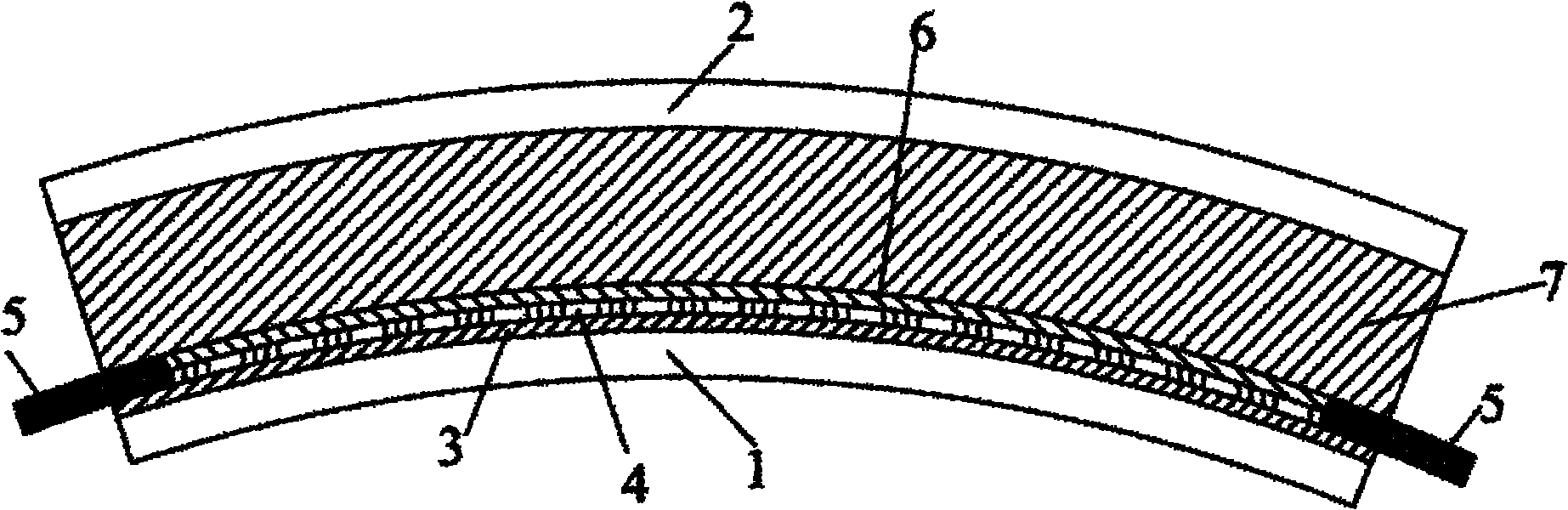

[0016] The pretreated outer glass substrate is coated, and a transparent conductive film 3 is deposited on the surface of the outer glass substrate towards the polymer PVB (polyvinyl butyral) 7. The transparent conductive film 3 can be a silver-based low-emissivity film, Or indium-doped tin oxide film, or fluorine-doped tin oxide film, or gallium-doped zinc oxide film, or aluminum-doped zinc oxide film.

[0017] The coated inner glass substrate and the outer glass substrate are stacked together for baking and bending treatment to obtain the inner glass substrate 1 and the outer glass substrate 2 in the geometrically curved shape required by the final product.

[0018] On the transparent conductive film 3 of the outer glass plate 2 that has completed the plating process of the transparent conductive film 3 and the baking and bending process, the electrode bus bar 5 of the energized heating electrode is bonded, and after the external lead wire for external power supply is reserve...

specific Embodiment approach 3

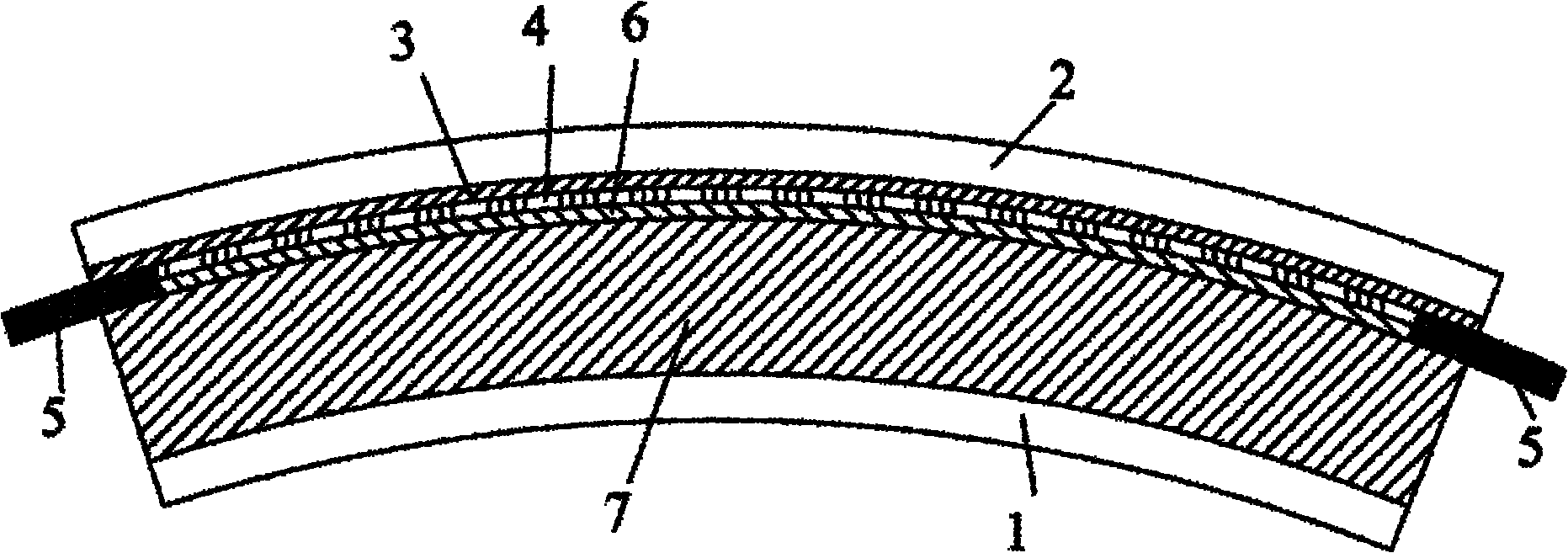

[0020] The pretreated inner glass substrate is coated, and a transparent conductive film 3 is deposited on the surface of the inner glass substrate towards the polymer PVB (polyvinyl butyral) 7. The transparent conductive film 3 can be a silver-based low-emissivity film , or indium-doped tin oxide film, or fluorine-doped tin oxide film, or gallium-doped zinc oxide film, or aluminum-doped zinc oxide film.

[0021] The coated inner glass substrate and the outer glass substrate are stacked together for baking and bending treatment to obtain the inner glass substrate 1 and the outer glass substrate 2 in the geometrically curved shape required by the final product.

[0022] On the top of the transparent conductive film 3 of the inner glass plate 1 after the deposition of the transparent conductive film and the baking and bending treatment, the electrode bus bar 5 for electric heating is bonded, and an external lead wire for external power supply is reserved.

[0023] On the surface...

specific Embodiment approach 4

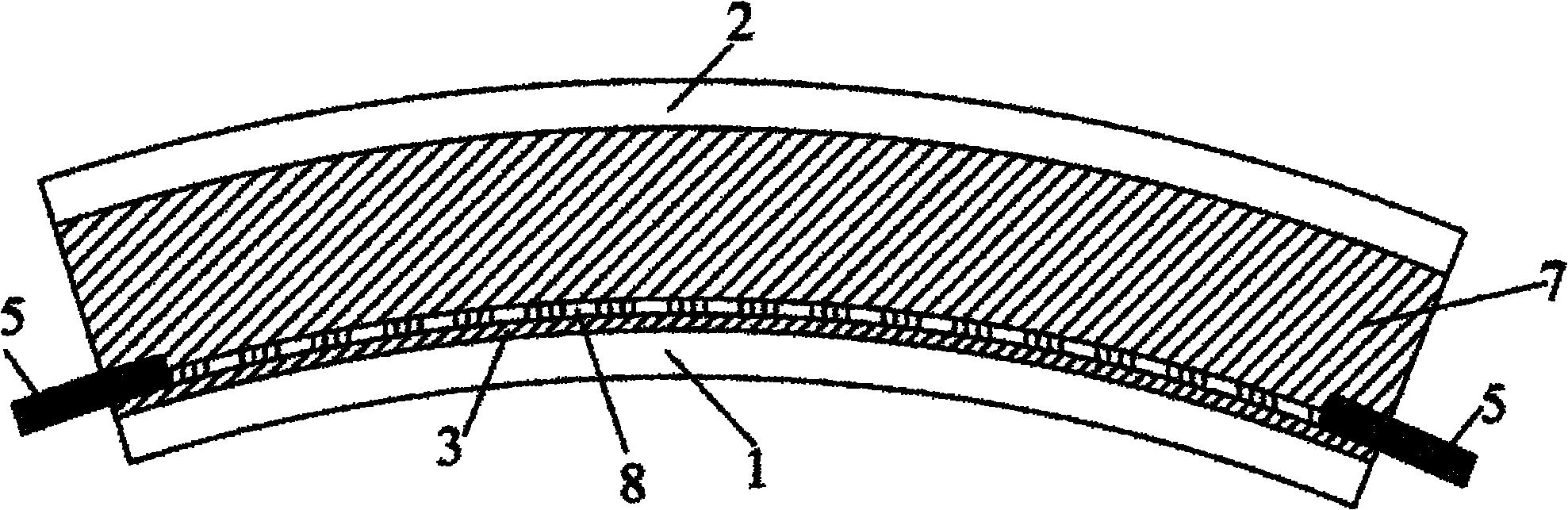

[0025] The pretreated outer glass substrate is coated, and a transparent conductive film 3 is deposited on the surface of the outer glass substrate towards the polymer PVB (polyvinyl butyral) 7. The transparent conductive film 3 can be a silver-based low-emissivity film, Or indium-doped tin oxide film, or fluorine-doped tin oxide film, or gallium-doped zinc oxide film, or aluminum-doped zinc oxide film.

[0026] The coated outer glass substrate and the inner glass substrate are stacked together and subjected to baking and bending treatment to obtain the inner glass substrate 1 and the outer glass substrate 2 in the geometrically curved shape required by the final product.

[0027] On the top of the transparent conductive film 3 of the outer glass plate 2 after the deposition of the transparent conductive film and the baking and bending treatment, the bus bar 5 of the electric heating electrode is bonded, and an external lead wire for external power supply is reserved.

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com