Method for preparing gamma-aluminium oxide (Al2O3) framework material by using erythromycin fungus dreg produced by fermentation method as core-shell material

A technology of erythromycin residues and skeleton materials, which is applied in the field of recycling of waste pharmaceutical residues, can solve problems such as inactivation, environmental protection, and waste of resources, and achieve low production costs, resource conservation, and no secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

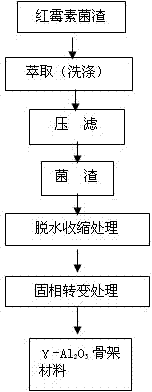

[0015] Example 1 see figure 1 , a production of erythromycin residue by fermentation as core-shell material to prepare γ-Al 2 o 3 The method of skeleton material, is characterized in that: use deionized water to extract erythromycin and amino acid from erythromycin slag produced by fermentation method, then press filter, and carry out syneresis on the slag after pressure filtration at 150°C Treatment (distillation) for 2 hours, followed by solid phase transformation treatment (thermal decomposition) at 680°C for 4 hours, to obtain γ-Al 2 o 3 Skeleton material.

[0016] γ-Al prepared by this example 2 o 3 Skeleton material with a pore size of 0.9nm and a specific surface area of 198m 2 / g.

Embodiment 2

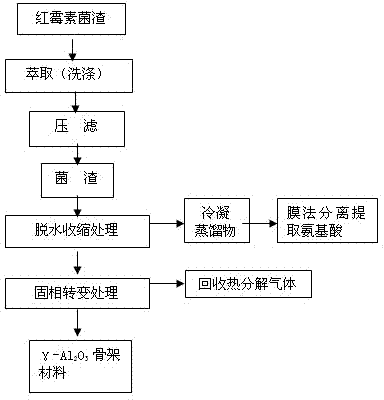

[0017] Example 2 see figure 2 , a production of erythromycin residue by fermentation as core-shell material to prepare γ-Al 2 o 3 The method of skeleton material, is characterized in that: use distilled water to extract erythromycin and amino acid from the erythromycin slag produced by fermentation method, then carry out pressure filtration under 5MP pressure, carry out pressure filtration at 190 ℃ to the slag after pressure filtration Syneresis treatment (distillation) for 3 hours, followed by solid phase transformation treatment (thermal decomposition) at 780°C for 5 hours to obtain γ-Al 2 o 3 Skeleton material.

[0018] γ-Al prepared by this example 2 o 3 Skeleton material with a pore size of 1.3nm and a specific surface area of 200m 2 / g.

[0019] In order to comprehensively utilize the erythromycin residue produced by the fermentation method of this example, the erythromycin and amino acids can also be extracted and separated from the filtrate after the above-...

Embodiment 3

[0020] Example 3 see figure 2 , a production of erythromycin residue by fermentation as core-shell material to prepare γ-Al 2 o 3 The method of skeleton material, is characterized in that: use deionized water to extract erythromycin and amino acid from the erythromycin residue produced by fermentation method, then carry out press filtration under 50MP pressure, and filter the press-filtered bacteria at 200°C The slag was subjected to syneresis treatment (distillation) for 4 hours, and then solid phase transformation treatment (thermal decomposition) at 800°C for 6 hours to obtain γ-Al 2 o 3 Skeleton material.

[0021] γ-Al prepared by this example 2 o 3 Framework material with a pore size of 1.4nm and a specific surface area of 205m 2 / g.

[0022] In order to comprehensively utilize the erythromycin residue produced by the fermentation method of this example, the erythromycin and amino acids can be extracted and separated from the filtrate after the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com