Method for comprehensively testing stability of deep ultraviolet optical element

A deep-ultraviolet light, comprehensive testing technology, used in testing optical performance and other directions to save costs and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

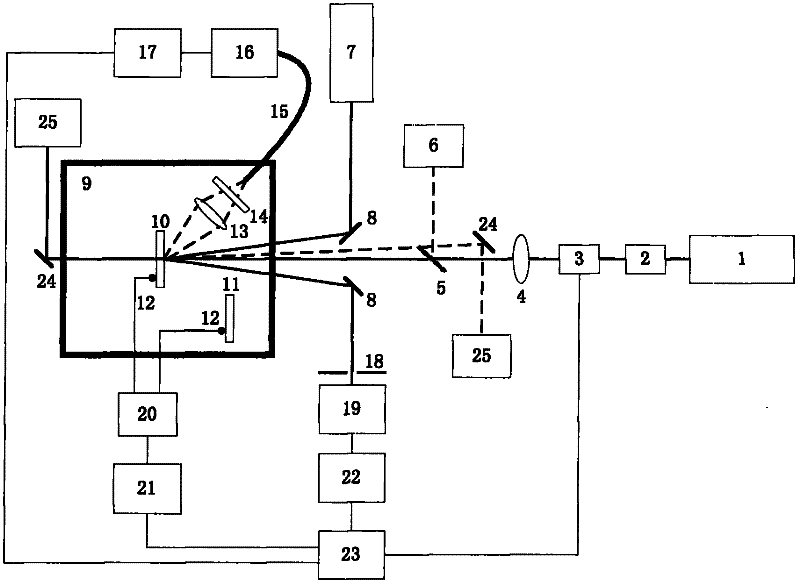

[0033] Such as figure 1 As shown, the present invention adopts the comprehensive test device of surface thermal lens technology by deep ultraviolet excimer laser light source 1, beam shaping system 2, electronically controlled variable optical attenuator 3, focusing lens 4, electric optical shutter 5, laser power meter 6 , detection laser light source 7, reflector 8, adiabatic sample chamber 9, tested sample fixture and measured deep ultraviolet optical element sample 10, reference sample fixture and reference sample 11, sensitive temperature detection unit 12, fluorescence collection optical system 13, narrowband Optical filter 14, coupling optical fiber 15, monochromator 16, fluorescence photodetection device 17, aperture diaphragm 18, photodetector 19, bridge amplifier circuit 20, A / D converter 21 and 22, computer 23, Reflector 24 and light absorber 25 are composed. When the output wavelength of the deep ultraviolet excimer laser light source is lower than 200nm, the entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com