Catalyst for selective catalytic reduction of nitrogen oxide in moderate/low temperature environment

A low-temperature environment, nitrogen oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problem of high catalyst cost, narrow catalyst temperature activity window, Poor thermal stability and other problems, to achieve the effect of easy to obtain raw materials, simple use conditions and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

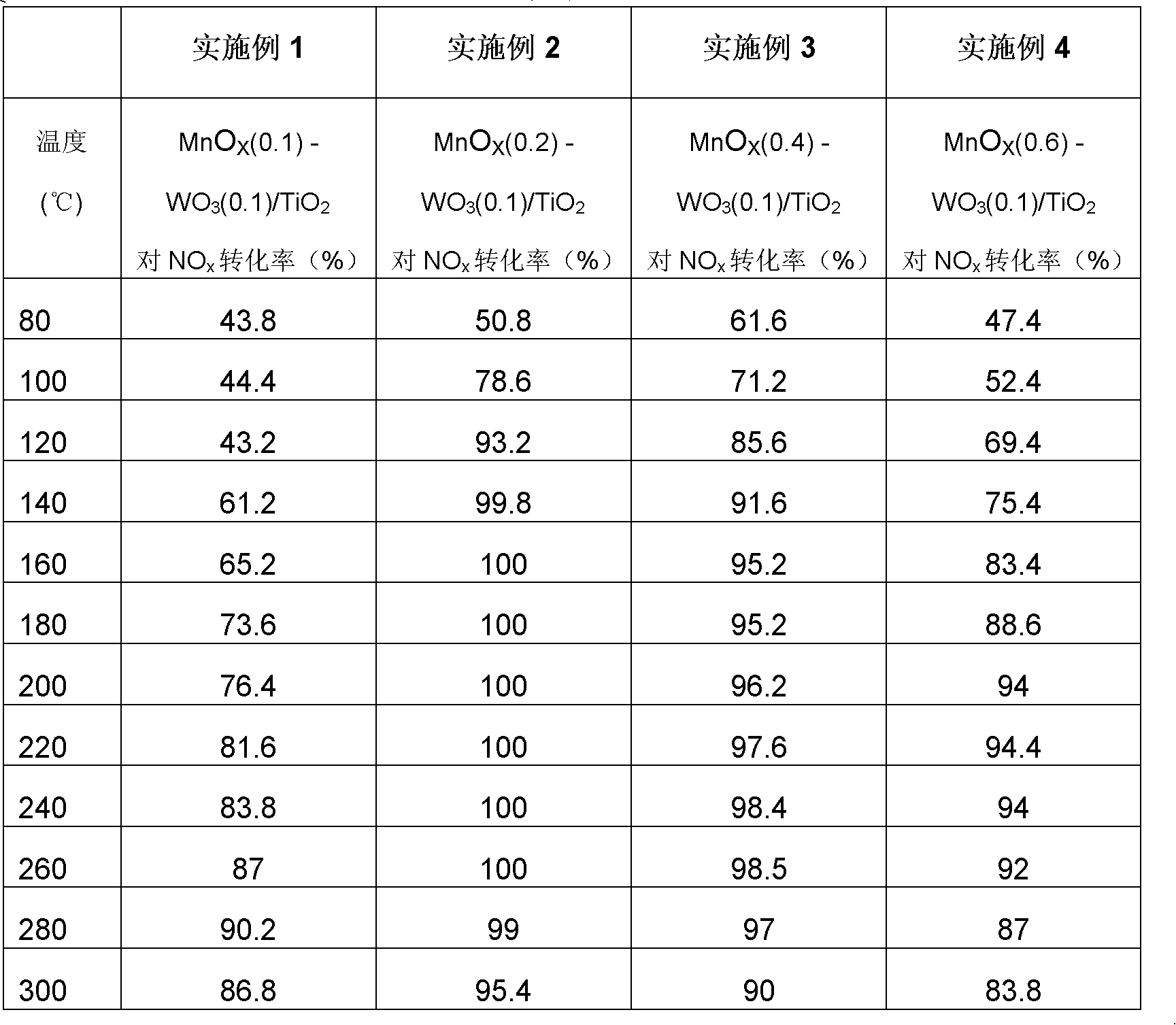

Embodiment 1~4

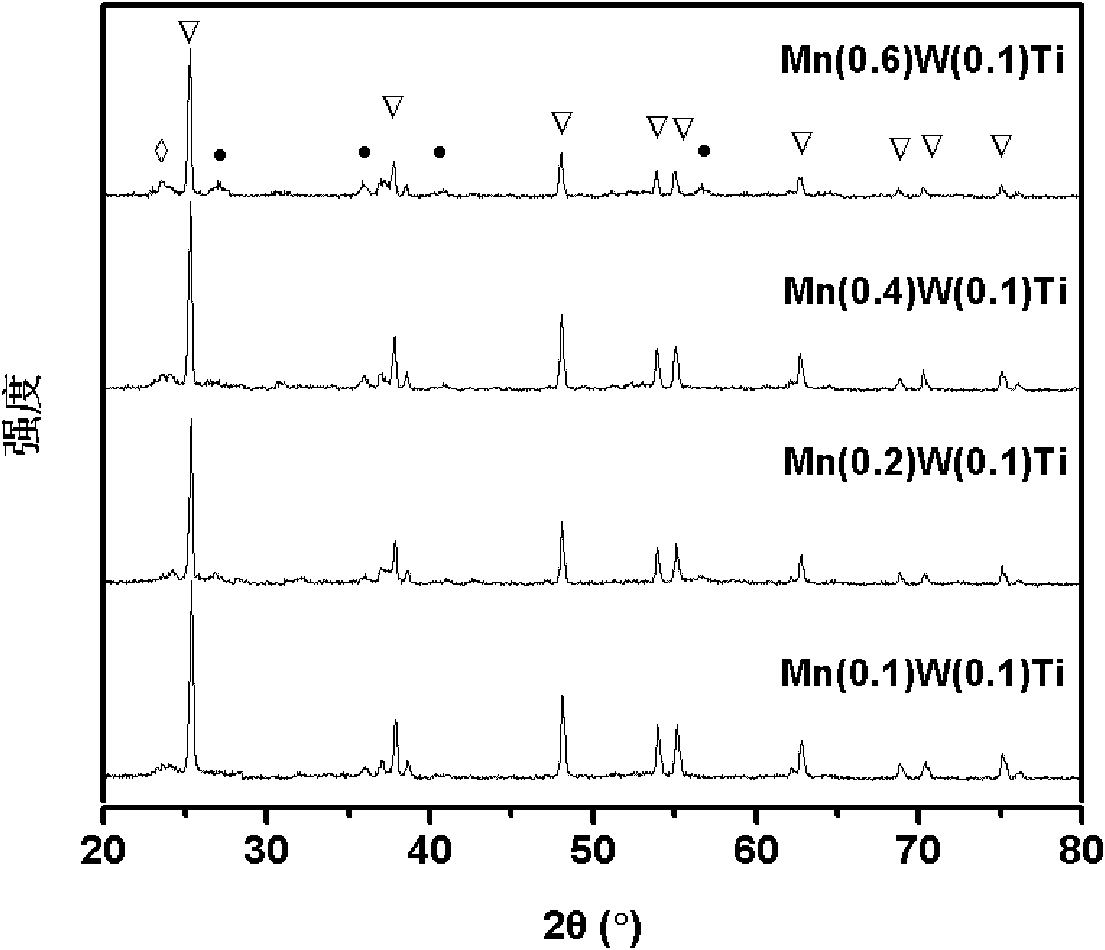

[0021] Weigh 8g of TiO with a single anatase phase in the particle size range of 30-40nm 2 Powder, mix and stir with 40ml deionized water to make TiO 2 Mix well with water to get TiO 2 slurry. Weigh 2.54g of hydrated ammonium tungstate and dissolve it in 30ml of a solution containing 5g of oxalic acid, heat until the hydrated ammonium tungstate is completely dissolved, then add to TiO 2 In the slurry, continue to stir for 2 hours, then continue to stir and evaporate to dryness in a water bath at 90°C until the mixture becomes viscous, then take it out and dry it in an oven at 120°C, grind it to 80 mesh to 100 mesh, and then dry it in the air Calcined at 500°C for 5 hours under the same conditions, after the muffle furnace was naturally cooled to room temperature, it was taken out and ground to 80 mesh to 100 mesh to obtain 10.34g WO 3 / TiO 2 carrier, where WO 3 with TiO 2 The molar ratio is 0.1:1, expressed as WO 3 (0.1) / TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com