Method for culturing marine oil-producing microalgae

A technology of oil-producing microalgae and cultivation method, which is applied to the high-density cultivation of marine oil-producing microalgae and the production of oil-rich marine microalgae biomass, can solve the problem of increasing the production cost of oil-rich microalgae and the cultivation density of marine microalgae. problems such as low energy consumption, increased energy input, etc., to achieve the effect of simplifying the accumulation process, low cost, and promoting accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

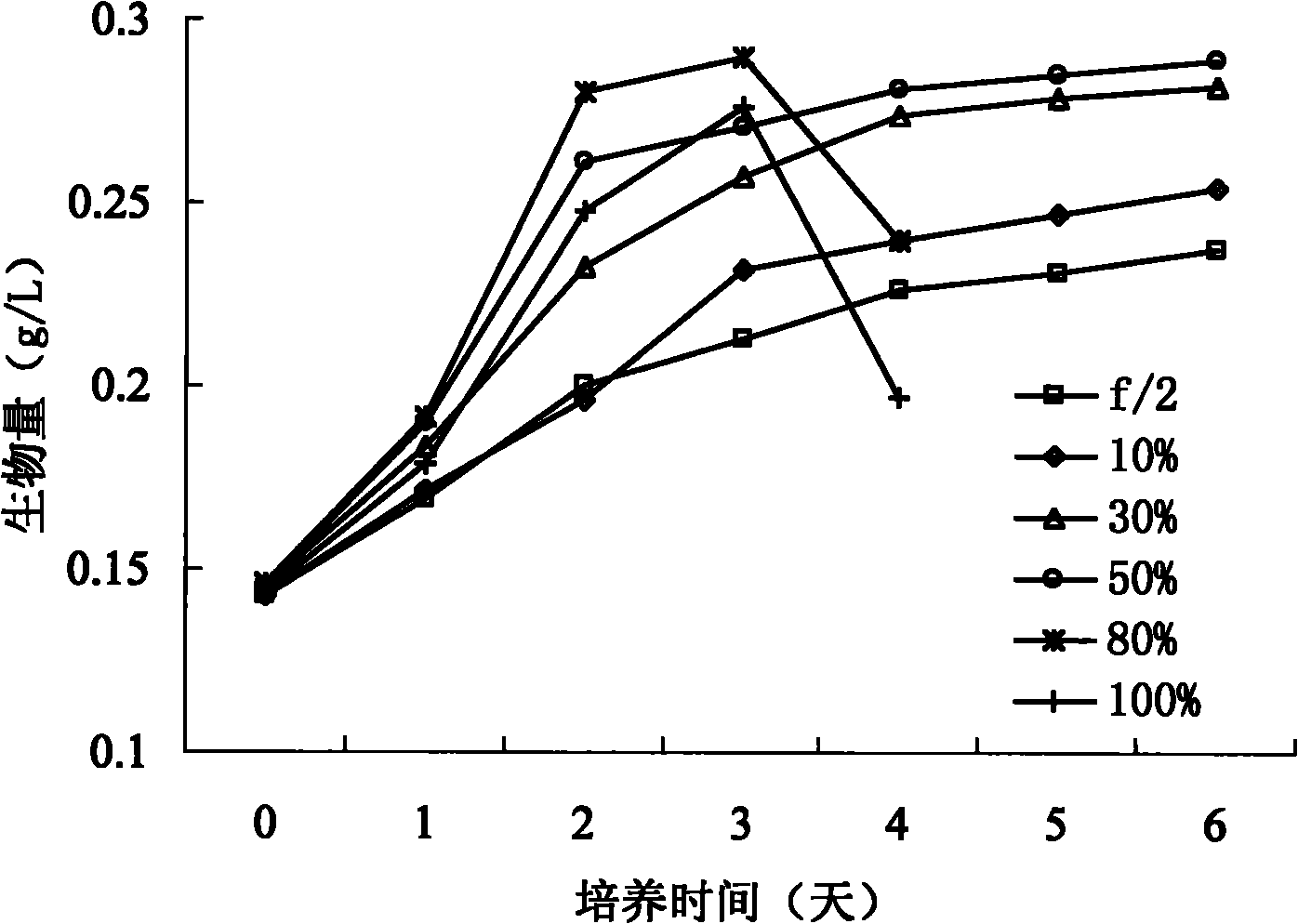

[0026] Step 1: Optimization of the proportion of domestic sewage. Based on natural seawater, add 10%, 30%, 50%, 80% and 100% of domestic sewage after secondary treatment and filtration, inoculate with fresh Nannochloropsis, and use conventional f / 2 culture medium as a control. At a temperature of 25°C and a light intensity of 70 μmolm -2 the s -1 Under the conditions of static culture for 6 days. refer to figure 1 , the results of many tests show that the more suitable proportion of domestic sewage is 30% to 50%, and the biomass accumulated by Nannochloropsis within this range is 1.2 to 1.6 times that of the control medium.

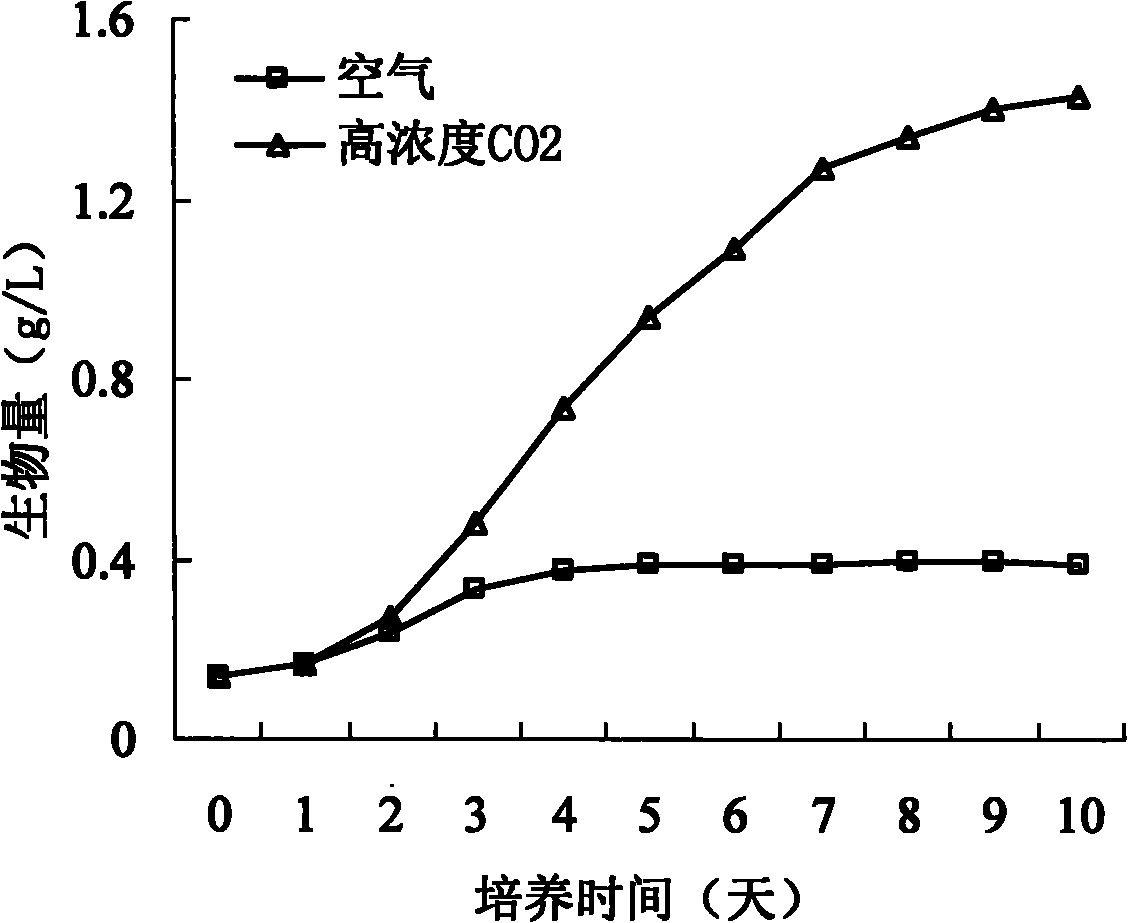

[0027] Step 2: using domestic sewage and high-concentration carbon dioxide to cultivate Nannochloropsis. Add 50% domestic sewage in natural seawater as a medium, add fresh Nannochloropsis algae, and feed 15% CO2 after 24 hours 2 Culture was carried out until the growth of Nannochloropsis cells entered the middle and late stages of logarithmic growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com