Micelle loaded with Tacrolimus or pharmaceutical salts thereof, lyophilized preparation as well as preparation methods and applications

A technology of tacrolimus and freeze-dried preparations, which is applied in the field of pharmaceutical dosage forms and nano-medicine preparations, can solve the problems of neurotoxicity, insensitivity, inability to move, mutism, seizures, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (1) 85 mg of methoxypolyethylene glycol poly(ε-caprolactone) polymer (MPEG 2000 -PCL 2000 ) and 15 mg of tacrolimus were dissolved in 2 ml of absolute ethanol, heated and stirred until completely dissolved to obtain a clear solution A;

[0085] (2) Under heating conditions, the clear solution A is rotary evaporated to remove the organic solvent to make it a transparent gel B;

[0086] (3) Add 5ml of preheated water for injection into gel B, make it clear and transparent under the condition of heating and stirring, and pass through a 0.22 μm filter membrane to obtain micelles C with a particle size of 10nm-100nm;

[0087](4) Freeze-dry the micelles C to obtain the final stable nano-medicine freeze-dried powder D; before the clinical use of the freeze-dried powder, adding water for injection will automatically form a sustained-release nano-sized glue under the condition of heating. bundle.

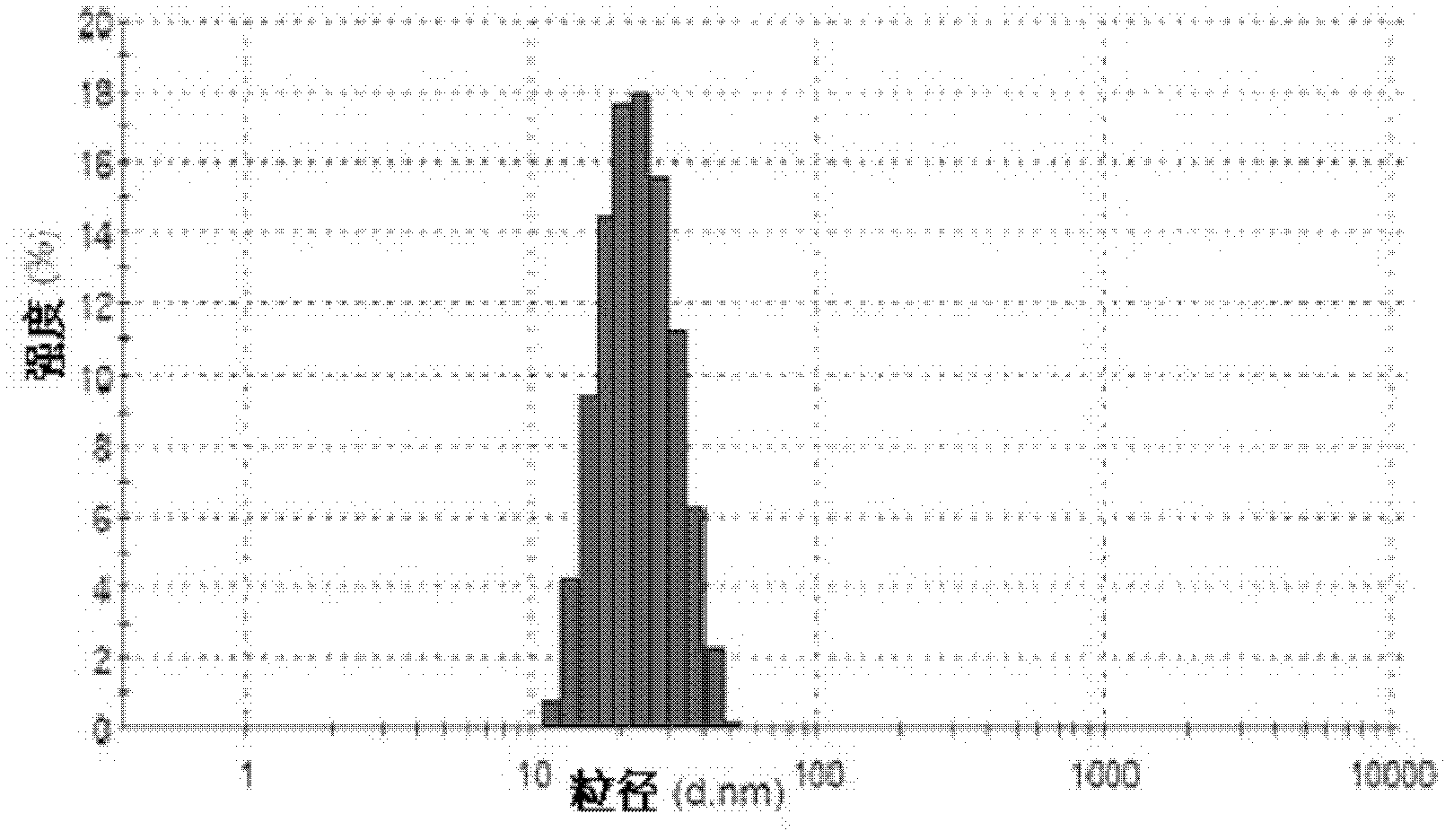

[0088] The obtained micelles C, lyophilized powder D and final reconstituted m...

Embodiment 2

[0090] (1) 92 mg of methoxypolyethylene glycol poly(ε-caprolactone) polymer (MPEG 2000 -PCL 2000 ) and 8 mg of tacrolimus were dissolved in 2 ml of absolute ethanol, heated and stirred until completely dissolved to obtain a clear solution A;

[0091] (2) Under heating conditions, the clear solution A is rotary evaporated to remove the organic solvent to make it a transparent gel B;

[0092] (3) Add 5ml of preheated water for injection into gel B, make it clear and transparent under the condition of heating and stirring, and pass through a 0.22 μm filter membrane to obtain micelles C with a particle size of 10nm-100nm;

[0093] (4) Freeze-dry the micelles C to obtain the final stable nano drug freeze-dried powder D.

[0094] Before the clinical use of the lyophilized powder, adding water for injection will automatically form sustained-release nano-sized micelles under the condition of heating.

[0095] The obtained micelles C, lyophilized powder D and the final reconstituted...

Embodiment 3

[0097] (1) 92mg poly(ε-caprolactone)-polyethylene glycol-poly(ε-caprolactone) triblock polymer (PCL 850 -PEG 2000 -PCL 850 ) and 8 mg of tacrolimus were dissolved in 2 ml of absolute ethanol, heated and stirred until completely dissolved to obtain a clear solution A;

[0098] (2) Under heating conditions, the clear solution A is rotary evaporated to remove the organic solvent to make it a transparent gel B;

[0099] (3) Add 5ml of preheated water for injection into gel B, make it clear and transparent under the condition of heating and stirring, and pass through a 0.22 μm filter membrane to obtain micelles C with a particle size of 10nm-100nm;

[0100] (4) Freeze-dry the micelles C to obtain the final stable nano-medicine freeze-dried powder D; before the clinical use of the freeze-dried powder, adding water for injection will automatically form a sustained-release nano-sized glue under the condition of heating. bundle.

[0101] The drug loading of the obtained micelles wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com