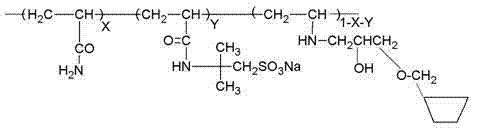

Acrylamide/2-acrylamido-2-methylpropane sulfonic acid sodium/cyclodextrin modified acrylamide (AM/AMPS-Na/MAM) copolymer and preparation method thereof

A technology of copolymer and amps-na, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as the gap in the performance maintenance of drilling fluids, etc., and achieve simple and feasible preparation methods, mild reaction conditions, and thermal stability. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation method of embodiment 1 AM / AMPS-Na / MAM copolymer fluid loss control agent

[0012] Add 200 mL of the prepared 0.1 g / L acrylamide AM aqueous solution into a 500 mL three-necked beaker, and then add 10 mL of the cyclodextrin-modified acrylamide MAM aqueous solution with a concentration of 0.4 g / L and 0.5 g / L 2- Acrylamido-2-methylpropanesulfonate sodium AMPS-Na aqueous solution 21mL; then add 1mL disodium edetate chelating agent with a concentration of 0.3g / L and potassium persulfate oxidant with a concentration of 0.5g / L in sequence 1mL

[0013] and 0.5 mL of sodium bisulfite reducing agent with a concentration of 1.0 g / L. After fully stirring and mixing uniformly on a magnetic stirrer, nitrogen protection deoxidizes, and reacts at 40-50° C. for 5-6 hours to obtain a transparent gel-like product AM / AMPS-Na / MAM copolymer.

[0014] Measure the intrinsic viscosity of AM / AMPS-Na / MAM copolymer according to the standard described in GB12005.1-89, and then meas...

Embodiment 2

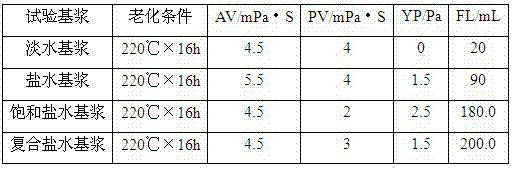

[0015] Example 2 The fluid loss control effect of AM / AMPS-Na / MAM copolymer

[0016] In order to evaluate the fluid loss reduction effect of AM / AMPS-Na / MAM copolymer at a higher temperature, the base slurry was prepared according to the national standard GB / T16783-1997. That is, add 2.5 g of anhydrous sodium carbonate and 20 g of bentonite to 500 mL of deionized water, stir at a high speed for 20 min, and then keep it sealed for 24 h to obtain a freshwater base slurry. Similarly, add 4% NaCl to 4% freshwater base slurry, stir at high speed for 20 minutes, then seal and stand for 24 hours to obtain salt water base slurry; add 38% NaCl to 4% freshwater base slurry, and then seal and stand still Set aside for 24 hours to obtain a saturated brine base slurry; in 500mL deionized water, add 22.5g NaCl, 2.5g anhydrous calcium chloride, 6.5g magnesium chloride hexahydrate, 75g calcium bentonite and 4.5g anhydrous sodium carbonate, stir at high speed for 20min, then seal and statically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com