Stripping liquid as well as preparation method and application

A technology of stripping liquid and organic solvent, which is applied in the field of stripping liquid and its preparation, can solve the problems of weak stripping performance, surface metal ion pollution, complex production process, etc., and achieve the effect of low corrosion and less corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

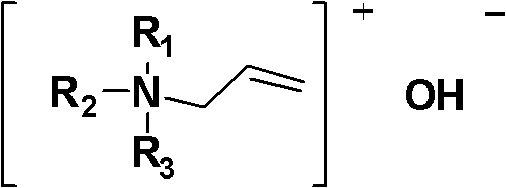

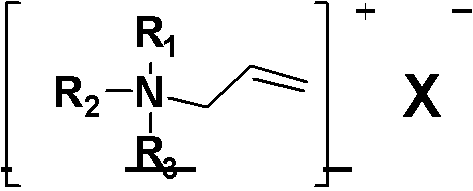

Method used

Image

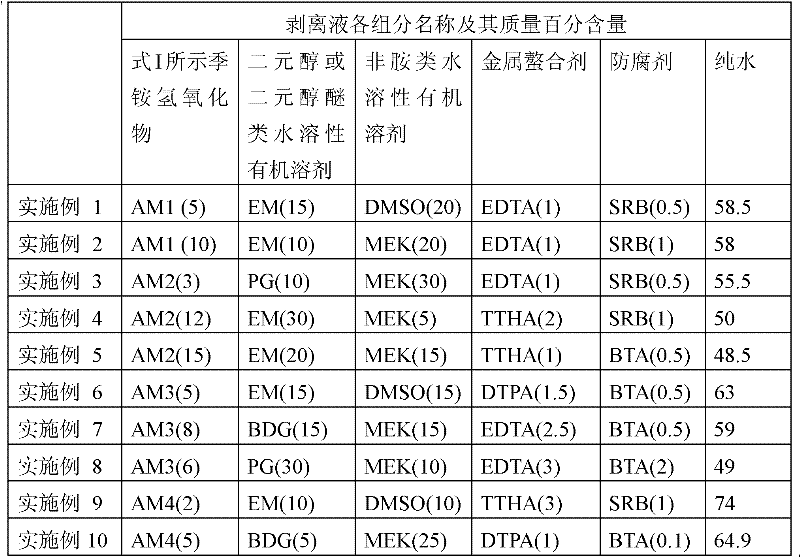

Examples

Embodiment 1

[0054] Trimethyl allyl ammonium hydroxide (AM1) 5 grams, glycol ethers water-soluble organic solvent ethylene glycol monomethyl ether (EM) 15 grams, non-amine water-soluble organic solvent dimethyl sulfoxide ( DMSO) 20 grams, metal chelating agent ethylenediaminetetraacetic acid (EDTA) 1 gram, preservative sorbitol (SRB) 0.5 grams and resistivity 20 megohms, total metal ion concentration is 58.5 grams of water of 50ug / L in Mix at room temperature to obtain the stripping solution provided by the present invention.

[0055] Among them, the water quality standards of the water used are shown in Table 3:

[0056] Table 3. Water Quality Standards

[0057] project

[0058] sodium

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com