Manufacturing method for silicon carbide monocrystals

一种制造方法、单晶的技术,应用在化学仪器和方法、单晶生长、单晶生长等方向,能够解决难输出光、无法基板使用、降低载流子密度SiC单晶着色等问题,达到载流子密度低、着色少、高效载流子密度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

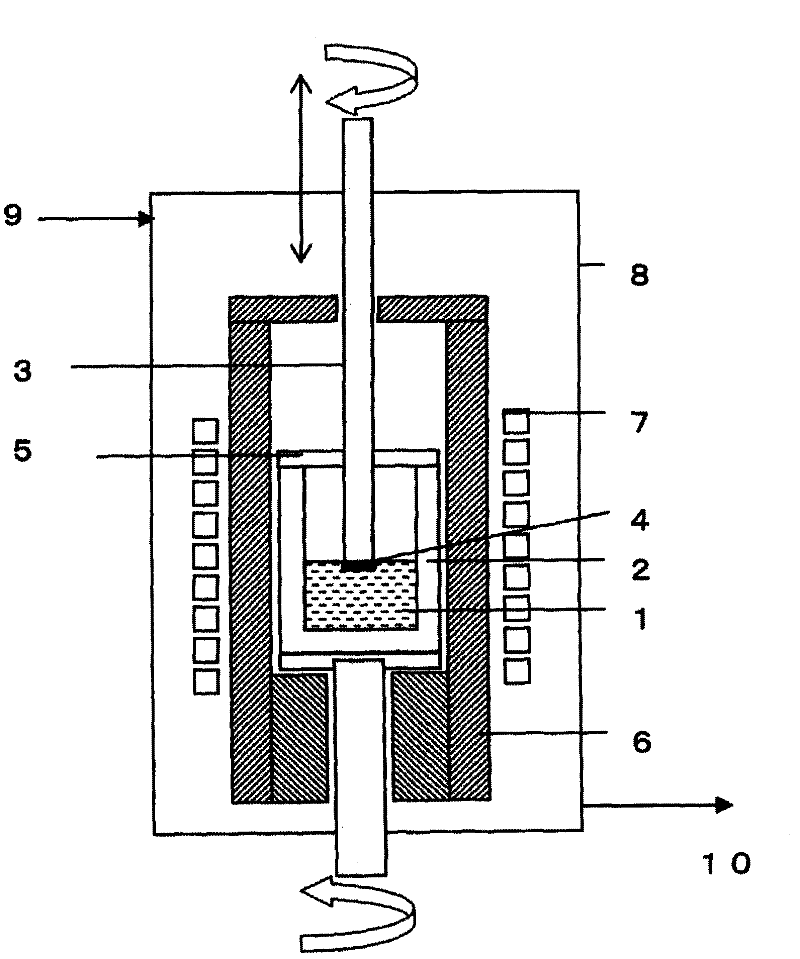

[0067] This example uses figure 1 In the shown single crystal manufacturing apparatus, a growth experiment of a SiC single crystal thin film was performed by the LPE method (temperature gradient method).

[0068] This single crystal manufacturing apparatus includes a high-purity graphite crucible 2 with an inner diameter of 80 mm and a height of 150 mm containing a SiC solution 1 in a molten state, and the crucible 2 is arranged in a water cooling chamber (stainless steel) 8 . The outer periphery of the graphite crucible is kept warm by a heat insulating material 6 , and a high frequency coil 7 for induction heating is provided on the outer periphery of the heat insulating material. The temperature distribution of the solution in the height direction can be controlled by adjusting the number of turns of the high-frequency coil, the pitch of the turns, and the relative positional relationship between the graphite crucible and the high-frequency coil. The atmosphere in the sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier concentration | aaaaa | aaaaa |

| carrier concentration | aaaaa | aaaaa |

| carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com