Shredder for mechanical disruption by gentle controlled compressive rotation

A technology of rotating elements and rotating rates, applied in the preparation of test samples, analytical materials, biochemical equipment and methods, etc., can solve the problems of incomplete splitting, unpredictability, unreliable splitting technology, etc., to achieve high productivity, high The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

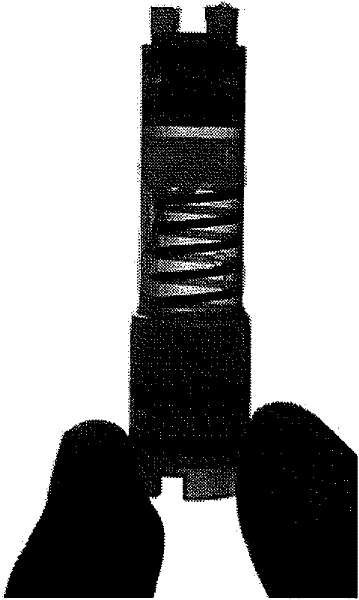

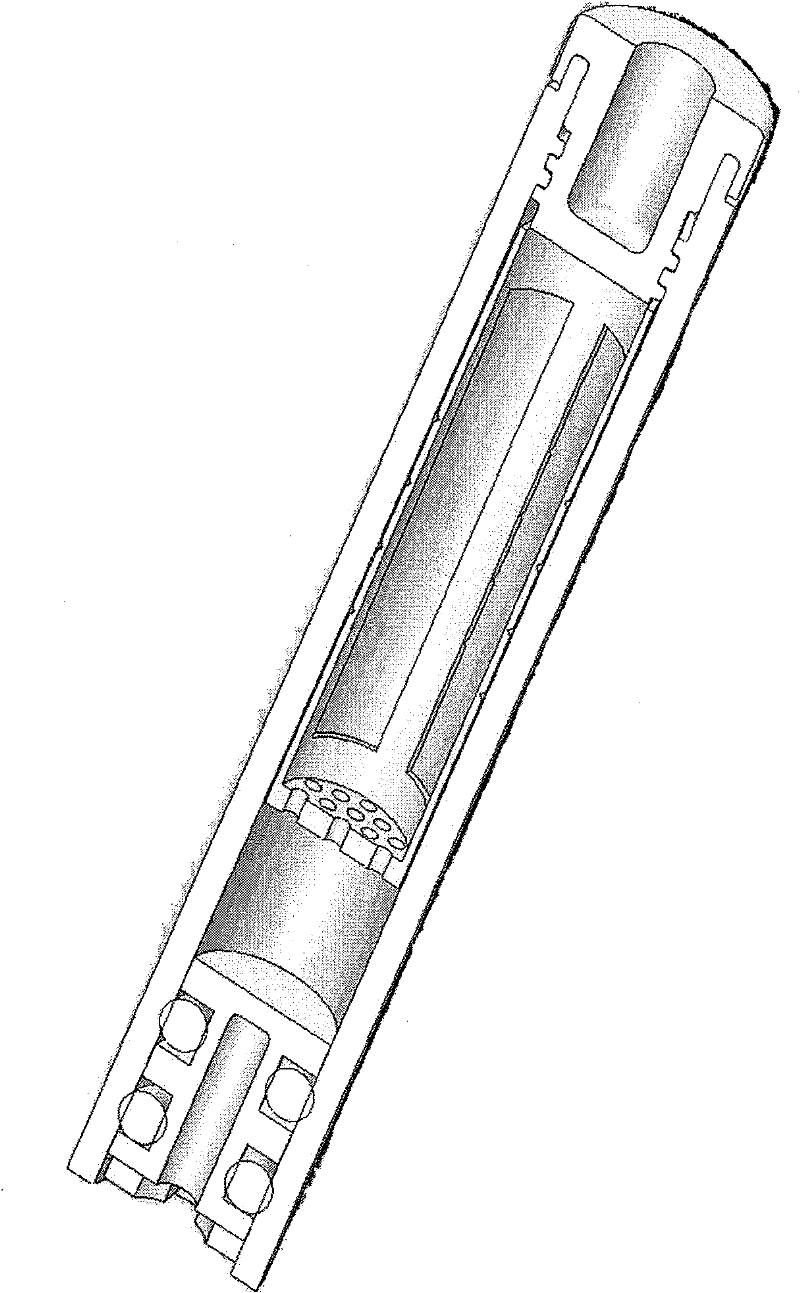

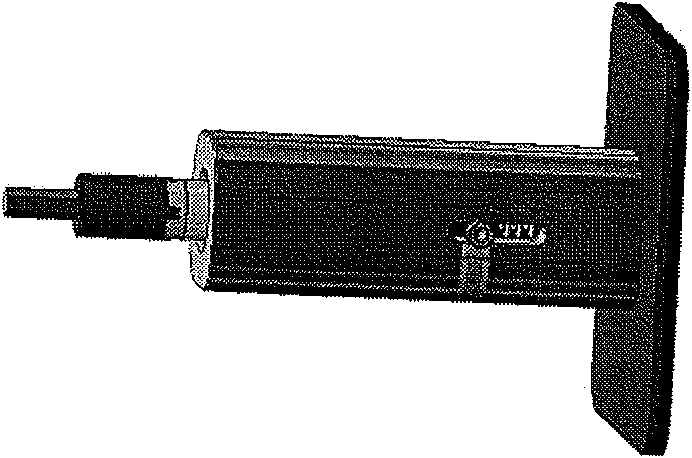

Image

Examples

example 1

[0057] Example 1. In physiological buffer or ProteoSOLVE TM In the case of IEF reagent, the pulverizer and BIOMASHER of the present invention when extracting protein from pine needles TM (From Nippi, Inc.) Comparison.

[0058] The pine needles are roughly cut to about 4-5mm length within one hour of harvest. 50 or 200mg is weighed to the tared PULSE Tubes or BioMasher TM Inset. Samples are in duplicate in KPO 4 Buffer or ProteoSOLVE IEF reagent with 100mM DTT.

[0059] As in Image 6 As shown in, for BioMasher TM In the centrifugal method, the components are centrifuged at 14,000 for 20 seconds under the condition that the homogenizer rod is positioned according to the manufacturer's instructions. BioMasher TM The insert is 80-140um micropore size. The insert was washed twice with 700 μL each time and centrifuged. Combine the initial homogenized product and washings. The final sample volume is 1400 μL. For BioMasher TM Rotating the grinding method, connect the homogenize...

example 2

[0076] Example 2. Using PCT Shredder TM And Pressure Cycle Technology (PCT) to increase protein productivity from coniferous plants

[0077] Plant proteins (proteome) provide an opportunity to monitor post-translational responses to environmental impacts such as pollution, pests, or plant diseases. Comprehensive protein analysis requires reliable extraction methods that can separate proteins reproducibly and without bias. The sample preparation of plant tissues is particularly complicated due to the fact that the nature of the cell wall makes it difficult to extract analytes quantitatively; the relatively low protein cell content in some plant tissues; or the abundance of lignin, tannic acid, and other polyphenols, This can interfere with protein analysis. The extraction of protein from pine needles or other coniferous tissues is particularly complicated and may be further complicated by their high content of terpene resin in these species. Here is a description of a system fo...

example 3

[0101] Example 3. Analysis of Tick Borrelia and HGE gene expression of DNA preparations separated by pulverizer and PCT: standard curve and total bacterial decomposition.

[0102] The basic method used for tick DNA extraction involves the following steps.

[0103] Before PCT, soak the tick sample in Tris buffer for 1 hour. A tick was loaded into the end of the punch and crushed by hand, followed by 60 cycles of PCT treatment in proteinase K at 56C. Place the test tube in boiling water and boil for 10 minutes, then unload. The CTAB buffer was added to a final concentration of 2% and allowed to incubate at 65C for 20 minutes. Carry out phenol-chloroform purification. Store the final volume of 100ul at -20C.

[0104] Perform real-time PCR. For the relative amounts of Borrelia and total bacterial DNA, two standard curves were designed. In doing so, the Borrelia DNA and E.coli DNA from ATCC were diluted in stages. Amplify the Borrelia 23S rRNA gene and the bacterial 16SrDBA gene.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com