Normal-pressure leaching method for simultaneously processing laterites with high iron content and high magnesium content

A simultaneous processing and laterite ore technology, applied in the field of nickel ore smelting, can solve problems such as long leaching time, difficulty, and environmental pollution, and achieve the effects of simplifying the smelting process, reducing equipment investment costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

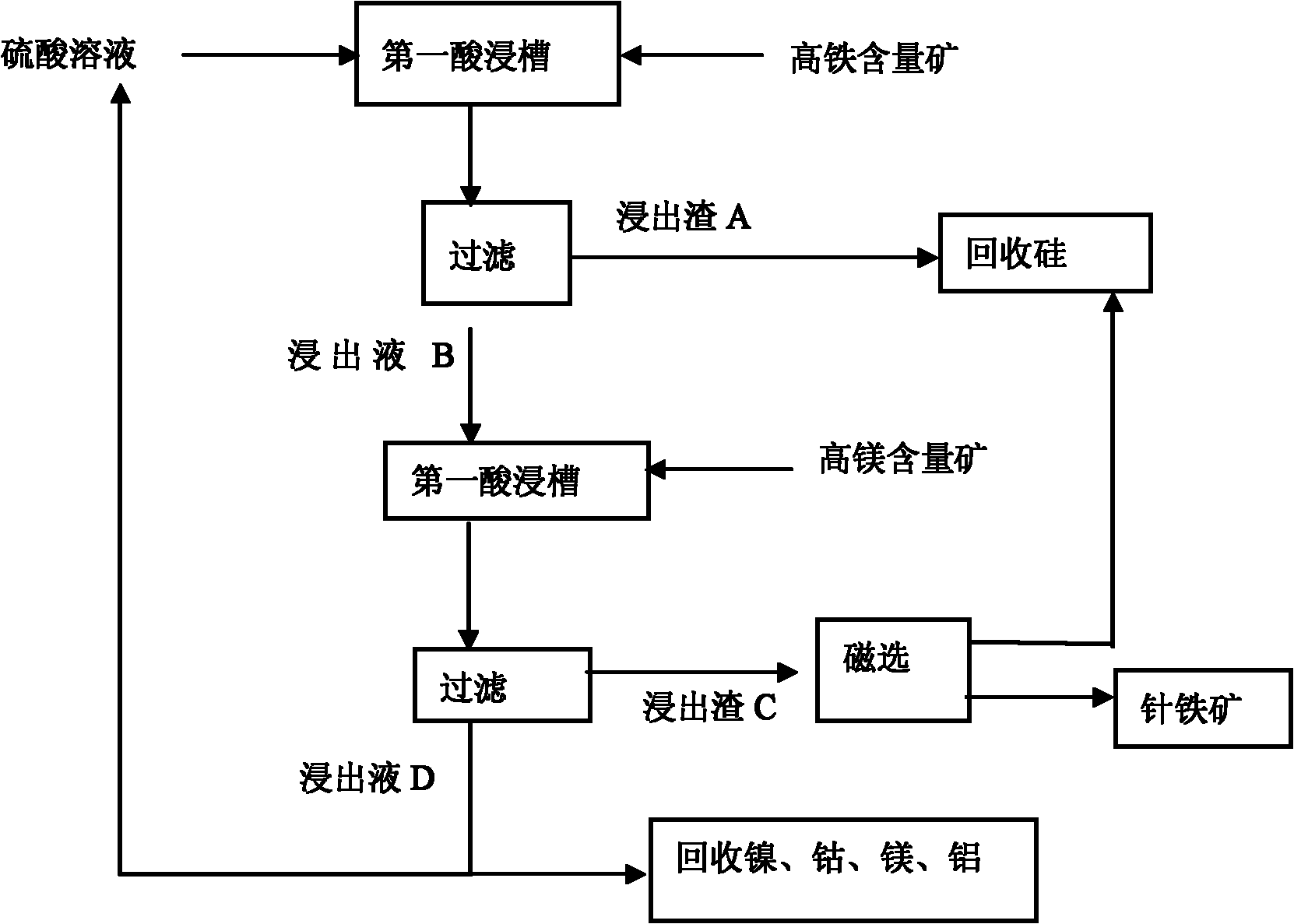

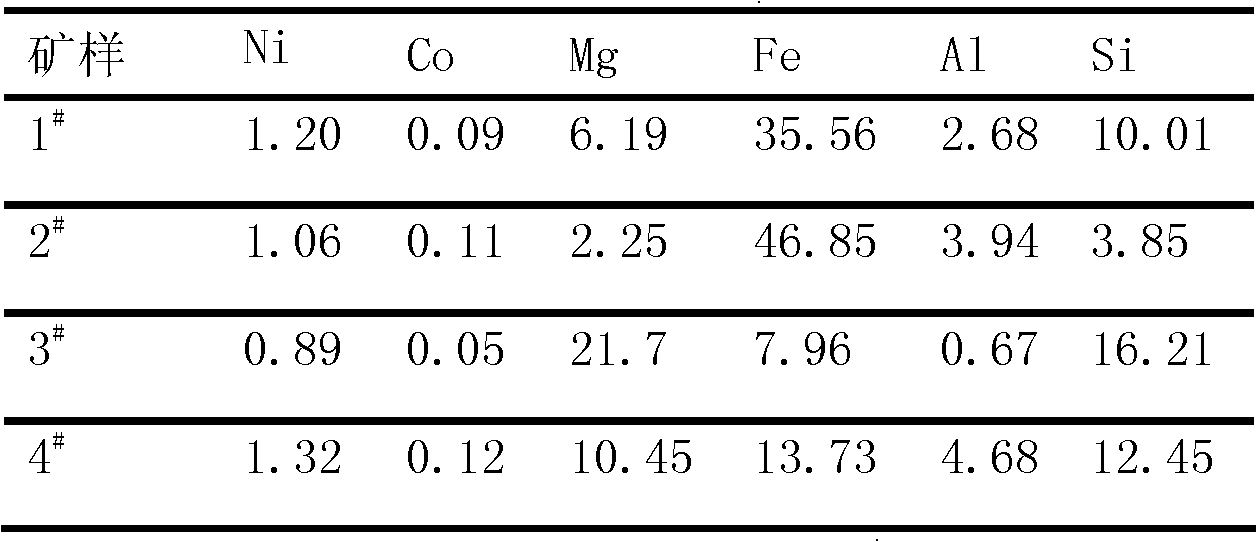

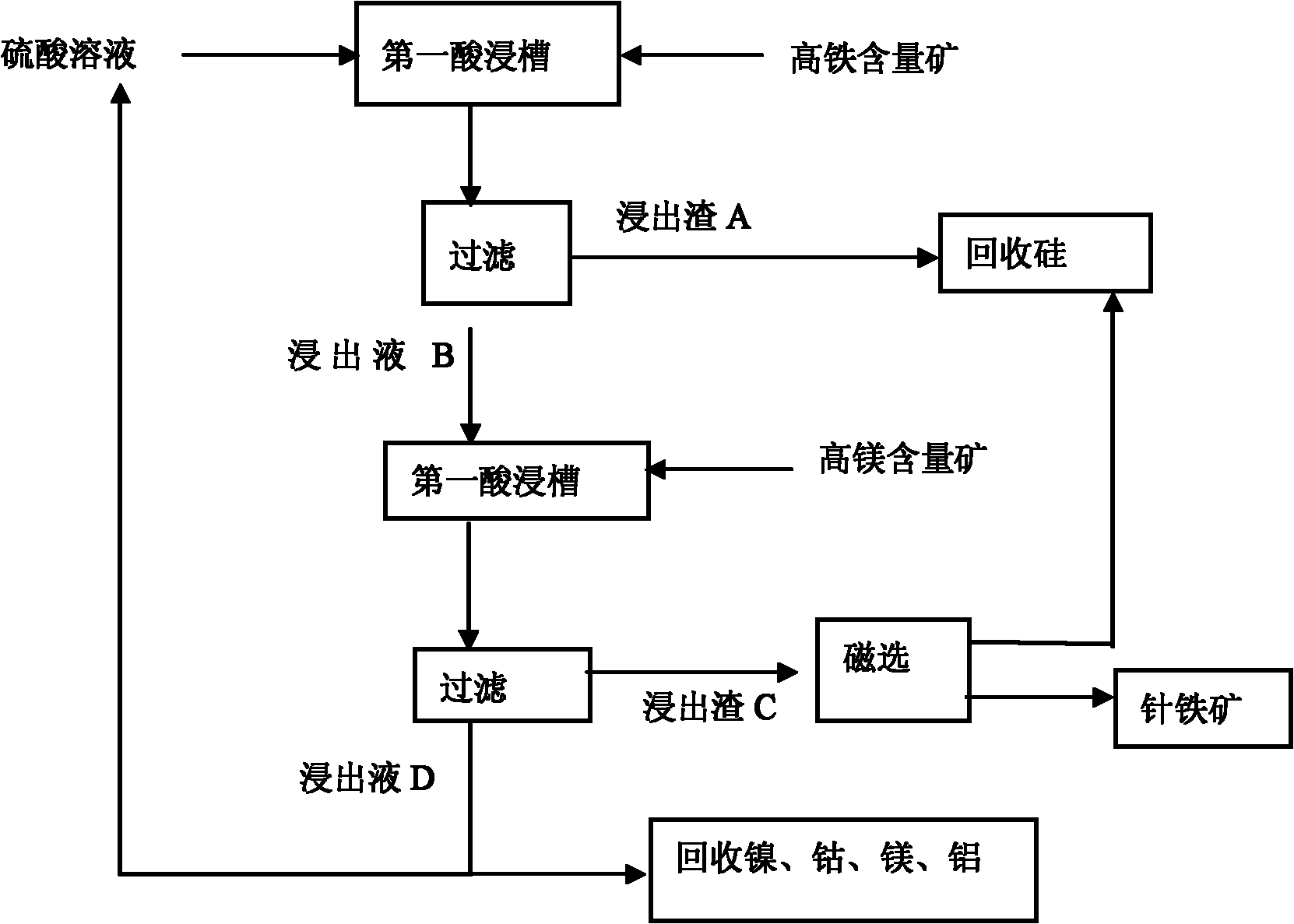

[0036] (1) the ore sample 1 # The aqueous ore slurry (solid-to-liquid mass ratio is 1:15) is added into the first acid leaching tank (it can be an atmospheric pressure stirring tank, the same below), and after adding 93% (w / w) sulfuric acid, the temperature is raised to 95 ° C, and leached for 1 hour, the obtained After the pulp is filtered, two parts are obtained: leaching slag A and leaching solution B;

[0037] (2) Leaching solution B is sent into the second acid leaching tank (can be an atmospheric pressure stirring tank, the same below), and the ore sample 3 # Added to the tank (mine sample 3 # The addition amount is ore sample 1 # 1.5 times, add ore sample 3 # Finally, the pH value of the leach solution B is 1.2), react at 100°C for 30 minutes, and filter the obtained pulp to obtain the leach residue C and the leach solution D;

[0038](3) Carry out magnetic separation to leaching slag C, obtain magnetic part E and non-magnetic part F, magnetic part E is sold as iron...

Embodiment 2

[0044] (1) the ore sample 1 # The aqueous pulp (solid-to-liquid mass ratio is 1:18) is added to the first acid leaching tank, after adding 93% (w / w) sulfuric acid, the temperature is raised to 80°C, and leached for 3 hours, and the obtained pulp is filtered to obtain leaching slag A and leaching solution B two parts;

[0045] (2) The leach solution B is sent into the second acid leaching tank, and the ore sample 3 # Added to the tank (mine sample 3 # The addition amount is ore sample 1 # 2 times, add ore sample 3 # Finally, the pH value of the leachate B is 2.5), react at 80°C for 1.5h, and filter the obtained pulp to obtain the leach residue C and the leachate D;

[0046] (3) Carry out magnetic separation to leaching slag C, obtain magnetic part E and non-magnetic part F, magnetic part E is sold as iron product, and non-magnetic part F is combined with leaching slag A for recycling silicon product;

[0047] (4) Get 80% of the leach solution D as a supplementary leaching ...

Embodiment 3

[0052] (1) the ore sample 2 # The aqueous pulp (solid-to-liquid mass ratio is 1:20) is added to the first acid leaching tank, after adding 98% (w / w) sulfuric acid, the temperature is raised to 100°C, and the leaching is performed for 0.5h. The obtained pulp is filtered to obtain leaching residue A and leaching liquid B two parts;

[0053] (2) The leach solution B is sent into the second acid leaching tank, and the ore sample 3 # Added to the tank (mine sample 3 # The addition amount is ore sample 2 # 2.5 times, add ore sample 3 # Finally, the pH value of the leachate B is 3.2), react at 75°C for 2.5h, and filter the obtained pulp to obtain the leach residue C and the leachate D;

[0054] (3) Carry out magnetic separation to leaching slag C, obtain magnetic part E and non-magnetic part F, magnetic part E is sold as iron product, and non-magnetic part F is combined with leaching slag A for recycling silicon product;

[0055] (4) Get 50% of the leaching solution D as a suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com