Method for preparing beta zeolite

A technology of beta zeolite and seed crystal, which is applied in the field of inorganic material synthesis and catalytic application, can solve the problem that the synthesis cost accounts for the main part, and achieve the effect of improving synthesis efficiency, reducing synthesis cost and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take 2.16 parts of TEABr template agent and 0.12 parts of organic accelerator A, add to 8.3 parts of 12% sodium hydroxide solution, stir and dissolve, then add 1.88 parts of sodium aluminate, continue to stir until the system is uniform and transparent, and then add 12.5 parts Slowly add silica sol to the above solution, and add 5 parts of solid silica gel under stirring, stir vigorously for 20 minutes, transfer to a closed stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallize at 140°C for 48 hours , and continued to crystallize at 160° C. for 32 hours, and the obtained product was filtered, washed and dried to obtain zeolite beta.

[0047] The molar ratio of raw materials in the reaction system is: Na 2 O / SiO 2 =0.12,H 2 O / SiO 2 =5, (TEA) 2 O / SiO 2 =0.03, SiO 2 / Al 2 o 3 =20.

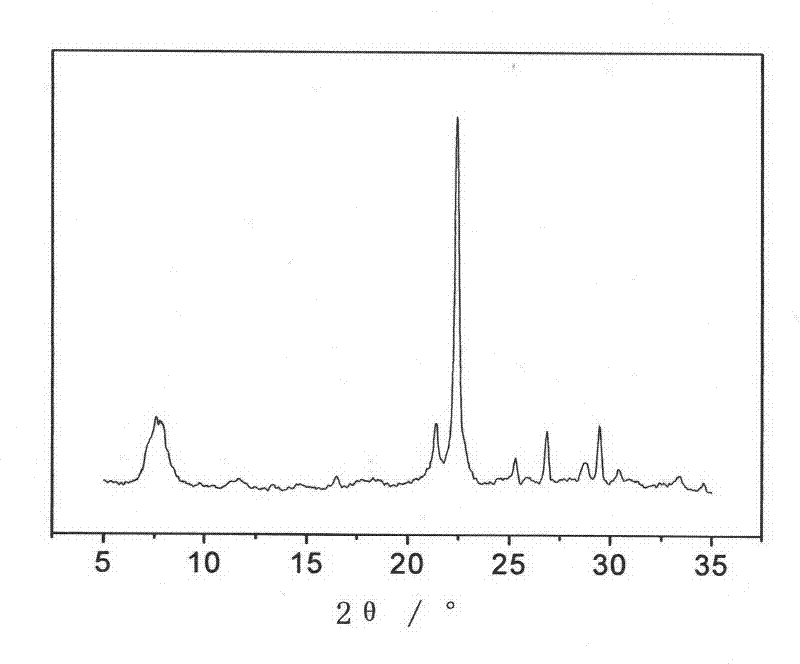

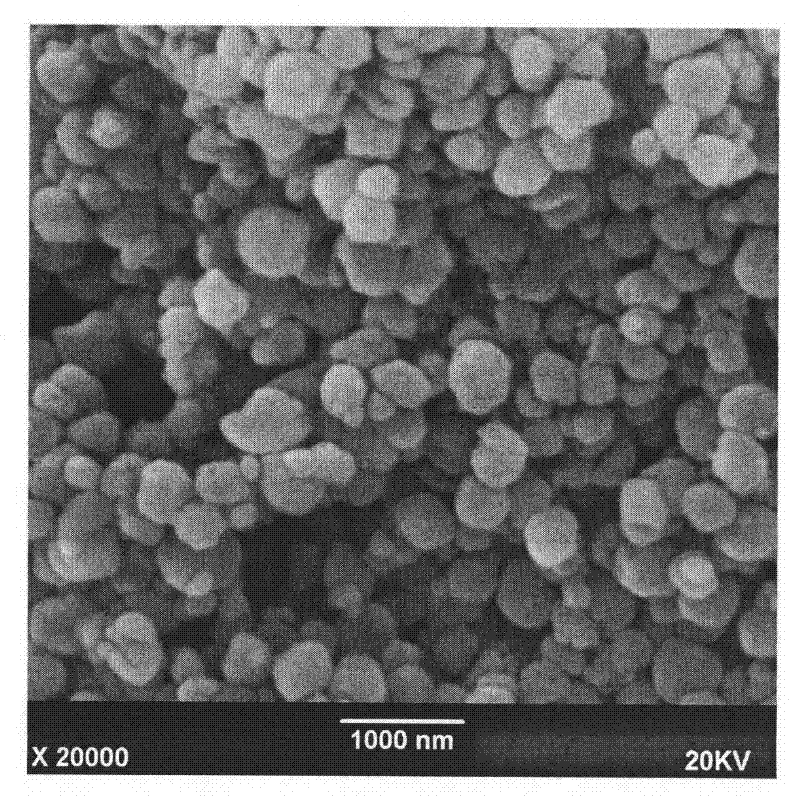

[0048] The relative crystallinity of the beta zeolite prepared in this example and the beta zeolite obtained in comparative example 1 is 106%. A small amou...

Embodiment 2~5

[0053] Preparation of the seed liquid: take the raw powder of zeolite beta, add it into 15% sodium hydroxide solution according to the solid-liquid ratio of 1:5.5, and treat it at 55° C. for 30 minutes.

[0054] According to the material ratio given in Table 1 and the addition of each substance, the specific steps are to first take TEABr template agent, organic accelerator A or inorganic accelerator C, add them to the sodium hydroxide solution under stirring, and stir to dissolve. , add pseudo-boehmite, continue to stir until the system is uniform, then add solid silica gel, stir vigorously, add seed liquid, continue to stir for 20 minutes, transfer to a closed stainless steel reaction kettle lined with polytetrafluoroethylene to crystallize The product was filtered, washed and dried to obtain zeolite beta.

[0055] The relative crystallinity of the product was determined by X-ray diffraction analysis, and the crystallinity of zeolite beta prepared in Comparative Example 1 was...

Embodiment 6~9

[0060] Preparation of the seed crystal liquid: take the raw powder of zeolite beta, add it into 12% sodium hydroxide solution at a solid-to-liquid ratio of 1:7, and treat it at 60° C. for 20 minutes.

[0061] According to the ratio of materials given in Table 1 and the addition of each material, feed intake, get TEABr template agent, surfactant (A is sodium dodecylbenzenesulfonate, B is cetyltrimethylammonium bromide ) and phosphate (C is magnesium phosphate, D is potassium hydrogen phosphate), added to the sodium hydroxide solution under stirring, after stirring and dissolving, adding sodium aluminate, continuing to stir until the system is uniform, then adding silica sol, solid silica gel, After vigorously stirring evenly, add a certain amount of seed liquid, continue stirring for 20 minutes, transfer to a closed stainless steel reaction kettle lined with polytetrafluoroethylene for crystallization, and filter, wash and dry the product to obtain zeolite beta. The amount of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com