Lactic acid bacteria starter for pickling vegetables

A technology of lactic acid bacteria fermentation and lactic acid bacteria, applied in bacteria, application, food preparation, etc., can solve the problems of destroying human liver and hematopoietic function, affecting blood oxygen carrying capacity, food safety issues, etc., to reduce the content of nitrite, shorten the Fermentation cycle, the effect of sour, crisp and refreshing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

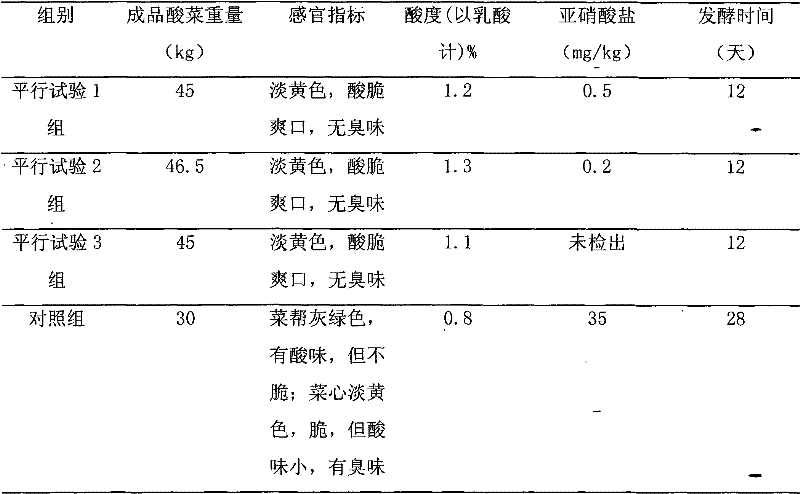

Examples

Embodiment 1

[0038] The 5 strains of lactic acid bacteria used in the present invention were all purchased from China Industrial Microorganism Culture Collection Center, which were: Lactobacillus plantarum CICC23138, Lactobacillus acidophilus CICC6006, Leuconostoc pseudoenterolis CICC22236, Lactococcus lactis subspecies CICC23198, cascara Lactobacillus sugarus CICC22151, the above-mentioned strains are referred to as bacteria A, bacteria B, bacteria C, bacteria D, and bacteria E in the present invention.

[0039] 1. Selection of fermentation strains and preparation of medium

[0040] Bacteria A—Lactobacillus plantarum CICC23138, the medium is 10.0g casein peptone, 10.0g beef extract, 5.0g yeast powder, 5.0g glucose, 5.0g sodium acetate, 2.0g diamine citrate, 801.0g Tween, K 2 HPO 4 2.0g, MgSO 4 .7H 2 O 0.2g, MnSO 4 .H2O 0.05g, CaCO 3 20.0g, distilled water 1.0L, pH6.8.

[0041] B bacteria——Lactobacillus acidophilus CICC6006, the culture medium is 5°Bé wort with 0.5% yeast extract and...

Embodiment 2

[0058] 1. Selection of fermentation strains and preparation of medium

[0059] Bacteria A—Lactobacillus plantarum CICC23138, the medium is 10.0g casein peptone, 10.0g beef extract, 5.0g yeast powder, 5.0g glucose, 5.0g sodium acetate, 2.0g diamine citrate, 801.0g Tween, K 2 HPO 4 2.0g, MgSO 4 .7H 2 O 0.2g, MnSO 4 .H2O 0.05g, CaCO 3 20.0g, distilled water 1.0L, pH6.8.

[0060] B bacteria——Lactobacillus acidophilus CICC6006, the culture medium is 5°Bé wort with 0.5% yeast extract and 0.6% sterile calcium carbonate.

[0061] Bacteria C——Leuconostoc pseudoenterolis CICC22236, the medium is 10.0g casein peptone, 10.0g beef extract, 5.0g yeast powder, 5.0g glucose, 5.0g sodium acetate, 2.0g diamine citrate, 801.0g Tween, K 2 HPO 4 2.0g, MgSO 4 .7H 2 O0.2g, MnSO 4 .H 2 O 0.05g, CaCO 3 20.0g, distilled water 1.0L, pH6.8.

[0062] Bacteria D——Lactococcus lactis subspecies CICC23198, the medium is tryptone 5.0g, soybean peptone 5.0g, beef extract 5.0g, yeast extract 2.5g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com