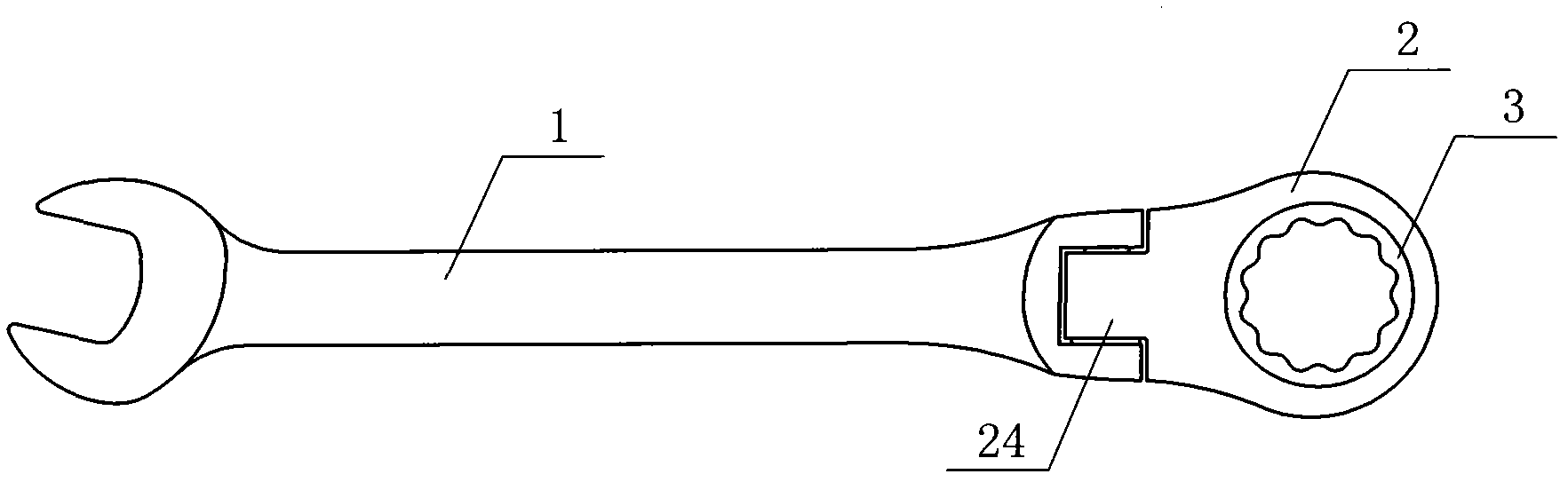

Connector for joint double offset ring ratchet spanner and manufacturing method thereof

A ratchet wrench and connector technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of poor machining accuracy, efficiency can only reach 60%, and decreased precision, and achieve dimensional accuracy and surface roughness improvement, raw material utilization The effect of high efficiency and stable size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

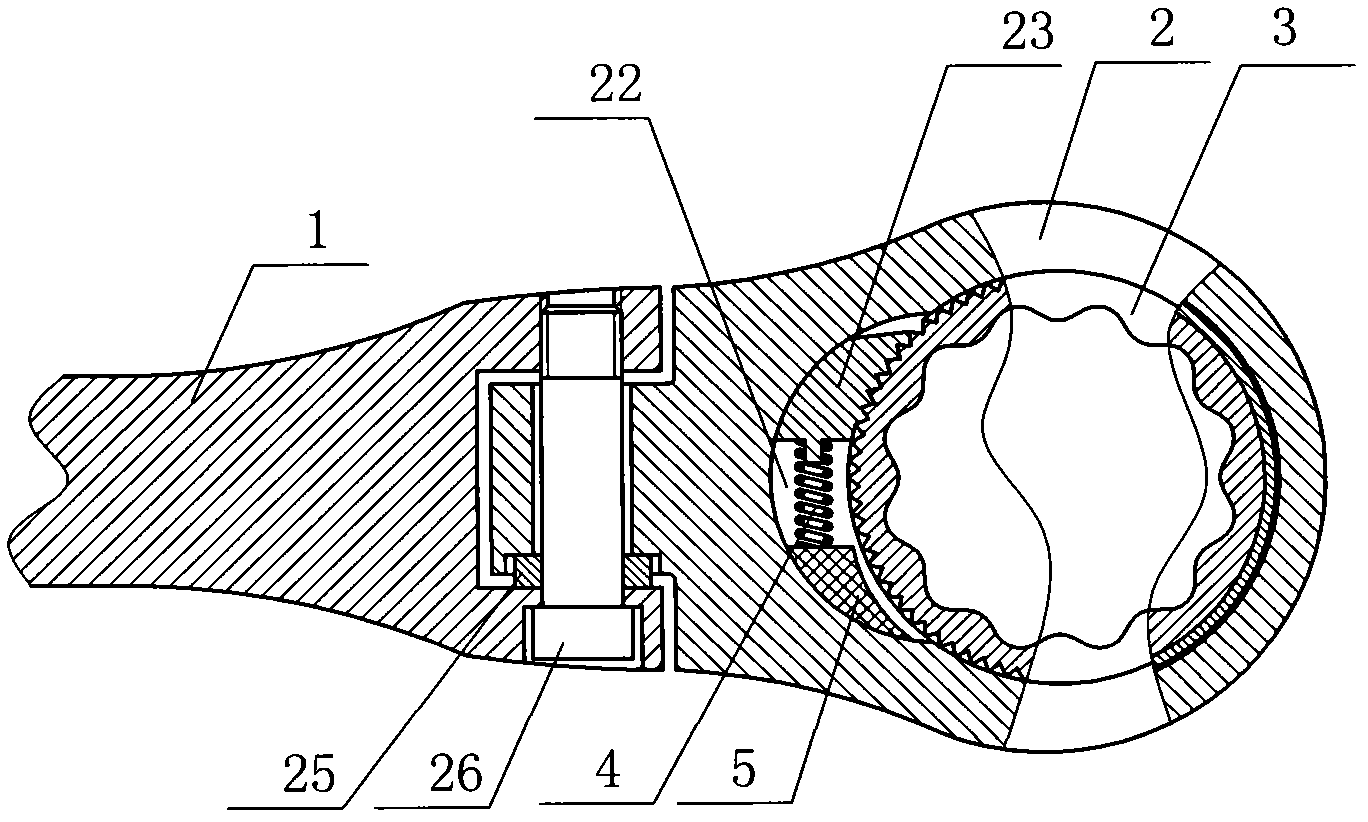

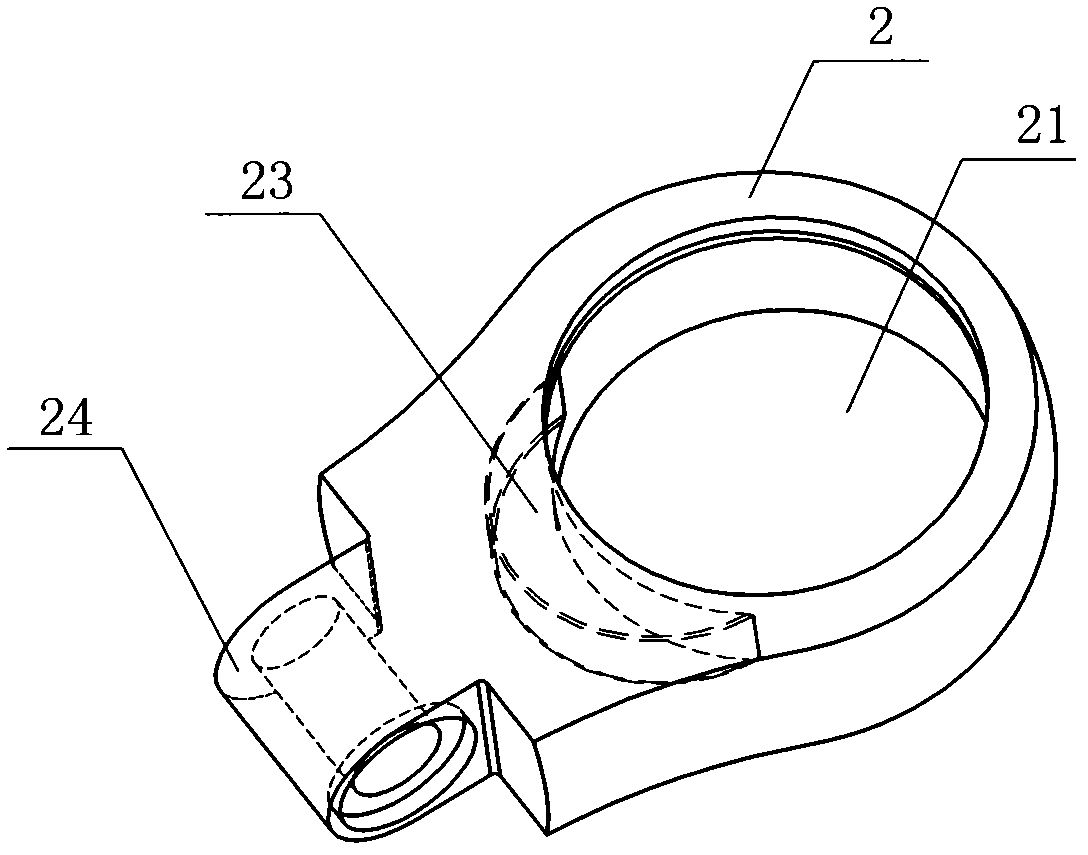

[0025] The connection head of the joint plum blossom ratchet wrench, the connection head is a powder metallurgy connection head.

[0026] The connecting head of the joint ring ratchet wrench, based on the weight percentage, the chemical composition of the connecting head includes 0.1-10% nickel; 0.1-5% molybdenum; 0.1-1.0% carbon; the balance is iron.

[0027] Prepare the metal powder containing the chemical components, based on weight percentage, carbonyl nickel powder accounts for 0.1-10% of the entire metal powder, reduced molybdenum powder accounts for 0.1-5% of the entire metal powder, and carbon accounts for 0.1-5% of the entire metal powder 1.0%, the remainder is carbonyl iron powder. Metal powder requirements: particle size 2-8um; bulk density 40-50%; tap density 50%; powder shape nearly spherical; aspect ratio 1.2-1.5. Metal powder is produced by hydroxyl method and atomization method.

[0028] Prepare the binder for forming. The binder cannot be separated from the ...

Embodiment 2

[0033] This embodiment is basically the same as the first embodiment, except that the chemical composition of the connecting head of the joint ring wrench is different.

[0034] In this embodiment, based on weight percentage, the chemical composition of the connector includes:

[0035] Nickel 3-5%; Chromium 15.5-17.5%; Carbon 0-0.07%; Copper 3-5%; Niobium + Tantalum 0.15-0.45%; Manganese 0-1.0%; Silicon 0-1.0%;

[0036] In this embodiment, a 17-4PH stainless steel connector can be manufactured, and the 17-4PH stainless steel metal powder is a metal powder produced by water atomization or gas atomization.

Embodiment 3

[0038] This embodiment is basically the same as the first embodiment, except that the chemical composition of the connecting head of the joint ring wrench is different.

[0039] In this embodiment, based on weight percentage, the chemical composition of the connector includes 10-14% nickel; 16-18% chromium; 2-3% molybdenum; 0-0.03% carbon; 0-2.0% manganese; -1.0%; balance iron.

[0040] In this embodiment, a 316L stainless steel connector can be manufactured, and the 316L stainless steel metal powder is produced by water atomization or gas atomization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com