Biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and bio-active water technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, can solve the problems of low nutrient content and few beneficial microorganisms, and achieve a wide range of raw material sources and stable fermentation quality , a wide range of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

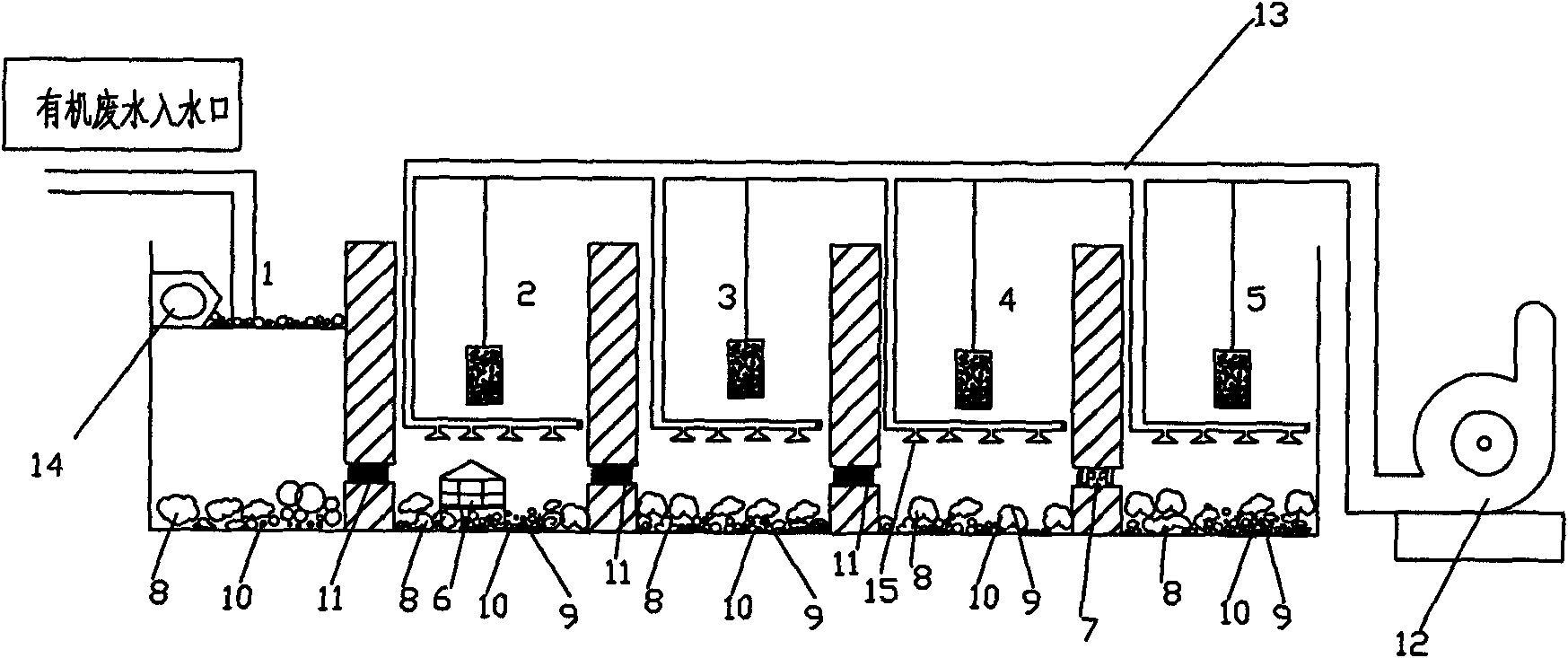

[0020] This embodiment provides a kind of equipment for manufacturing biologically active water, such as figure 1 As shown, it includes an air flotation filter tank 1, an adjustment tank 2, a fermentation and decomposition tank 3, an aerated biological tank 4, and a product storage tank 5, and the above-mentioned tanks are connected to each other in turn.

[0021] The air flotation filter tank 1 is equipped with an air flotation filter device 14, and there are sludge 8 and microbial flora 10 inside. The tank is 1-3m away from the bottom and has a porous partition 11 connected with the adjustment tank 2; the adjustment tank 2 has a Microorganism generating device 6; fermentation and decomposition tank 3 communicates with adjustment tank 2 and aeration tank 4 through porous partition 11; aeration tank 4 sends the final product into the product storage tank without power through glass fiber non-woven filter plate 7 5; wherein sludge 8, microbial flora 10, volcanic rock 9 and aera...

Embodiment 2

[0023] The present embodiment provides a method for manufacturing biologically active water, which may include the following steps:

[0024] (1) The organic sewage is discharged into the air flotation filter tank 1, and the air flotation filter equipment 14 scrapes scum, discharges scum, and generates microbubbles, wherein the amount of microbial flora 10 in the sewage is 300-3000mg / L, the process The COD removal rate is 5-20%. The preliminarily treated sewage is discharged into the adjustment tank 2 through the porous partition 11 .

[0025] (2) The sewage flowing into the adjustment tank 2 will increase the oxygen in the sewage to 1-2.5mg / L through the action of factors such as the air supply pipe 13, the sludge 8, the fan 12 and the aeration equipment 15, and control the microbial generation equipment The amount of microorganisms produced in the sewage is 3000-8000 mg / L. Through this process, 10-30% of COD is further removed under the conditions of step (1), wherein the hy...

Embodiment 3

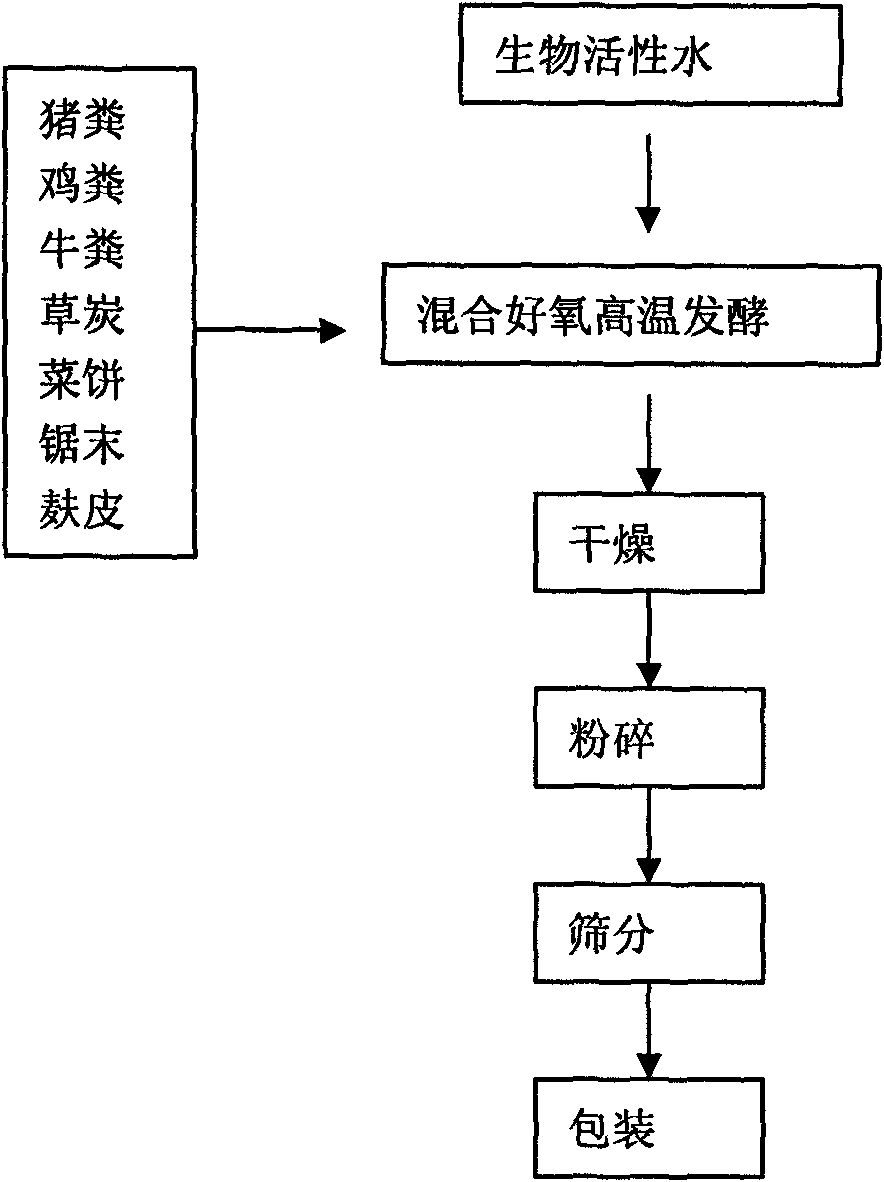

[0041] The present embodiment provides a method for utilizing the above-mentioned biologically active water to manufacture bio-organic fertilizers, adding 5%: 30%: 15%: 15% to pig manure, chicken manure, cow dung, grass charcoal, vegetable cakes, sawdust, and bran respectively. %: 5%: 15%: 10% weight ratio mixed evenly to make a mixture, then spraying concentration is 15% biologically active water 5%, while adjusting the pH to between 6.9~8.9; will add the mixture of biologically active water The stacking begins to ferment, and the stacking position formed by stacking the mixture is 25 cubic meters, with a height of 3 meters. After stacking, turn the pile once every 2 to 7 days (when the temperature in the pile reaches 50°C), carry out fermentation, and ferment again until the ripening is completed. The obtained decomposed materials are dried, crushed, screened, and packaged to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com