Polyimide coating with high-temperature resistance and preparation method thereof

A technology of polyimide and polyimide resin, which is applied in the field of high-temperature-resistant polyimide coatings and its preparation, can solve the problem that the heat-resistant grade cannot reach high-temperature resistance, and the qualification rate and reliability of devices cannot be guaranteed and other issues to achieve the effect of low cost, easy adjustment, and convenient source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

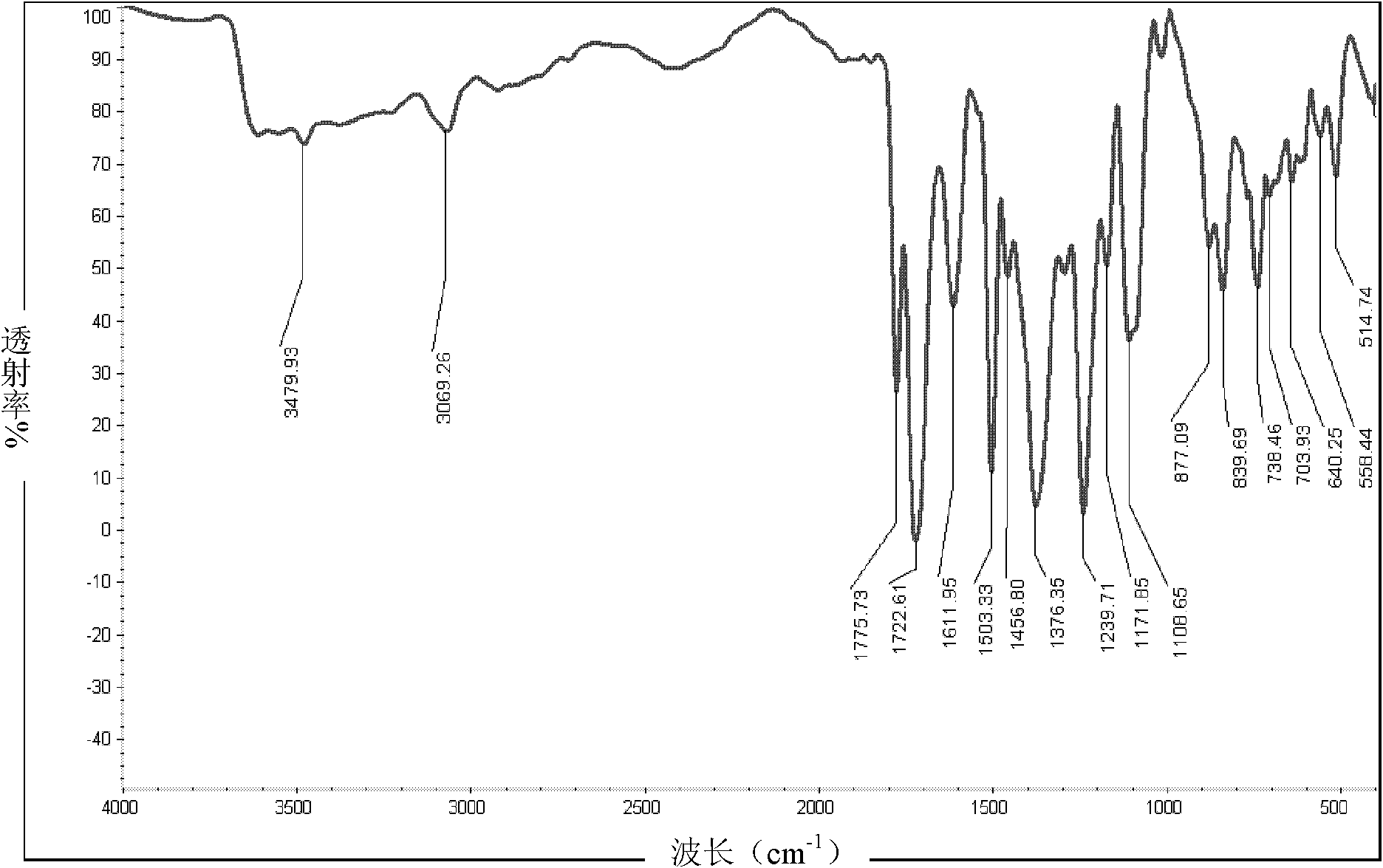

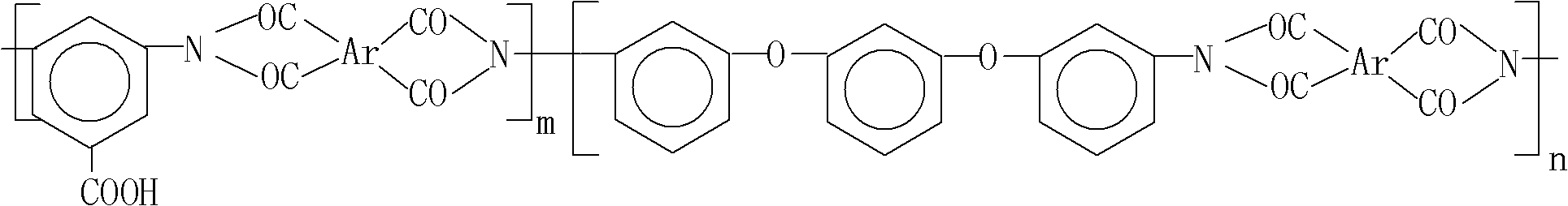

[0043] 15.20 grams (0.1 moles) of 3,5-diaminobenzoic acid, 2.92 grams (0.01 moles) of 1,3-bis(3-aminophenoxy)benzene and 220 milliliters of N-methyl-2-pyrrolidone strongly polar Put the aprotic organic solvent into the reaction kettle, at room temperature, after stirring and dissolving completely, add 32.34 grams (0.11 moles) of aromatic dibasic acid anhydride powder of 3,3',4,4'-tetracarboxylic biphenyl dianhydride, at room temperature After stirring and reacting for 1.5-2 hours, a homogeneous transparent viscous resin solution was obtained; 44 ml of toluene azeotropic dehydrating agent was added, and after azeotropic reflux and water separation for 4-5 hours, 70 ml of azeotropic dehydrating agent and Part of the strong polar aprotic organic solvent to obtain a reactive polyimide resin solution with a solid content of 20%-25%, denoted as BPI206; take out a small amount of resin solution, remove the solvent, and dry to obtain a dry reactive polyimide resin solution Polyimide r...

Embodiment 2

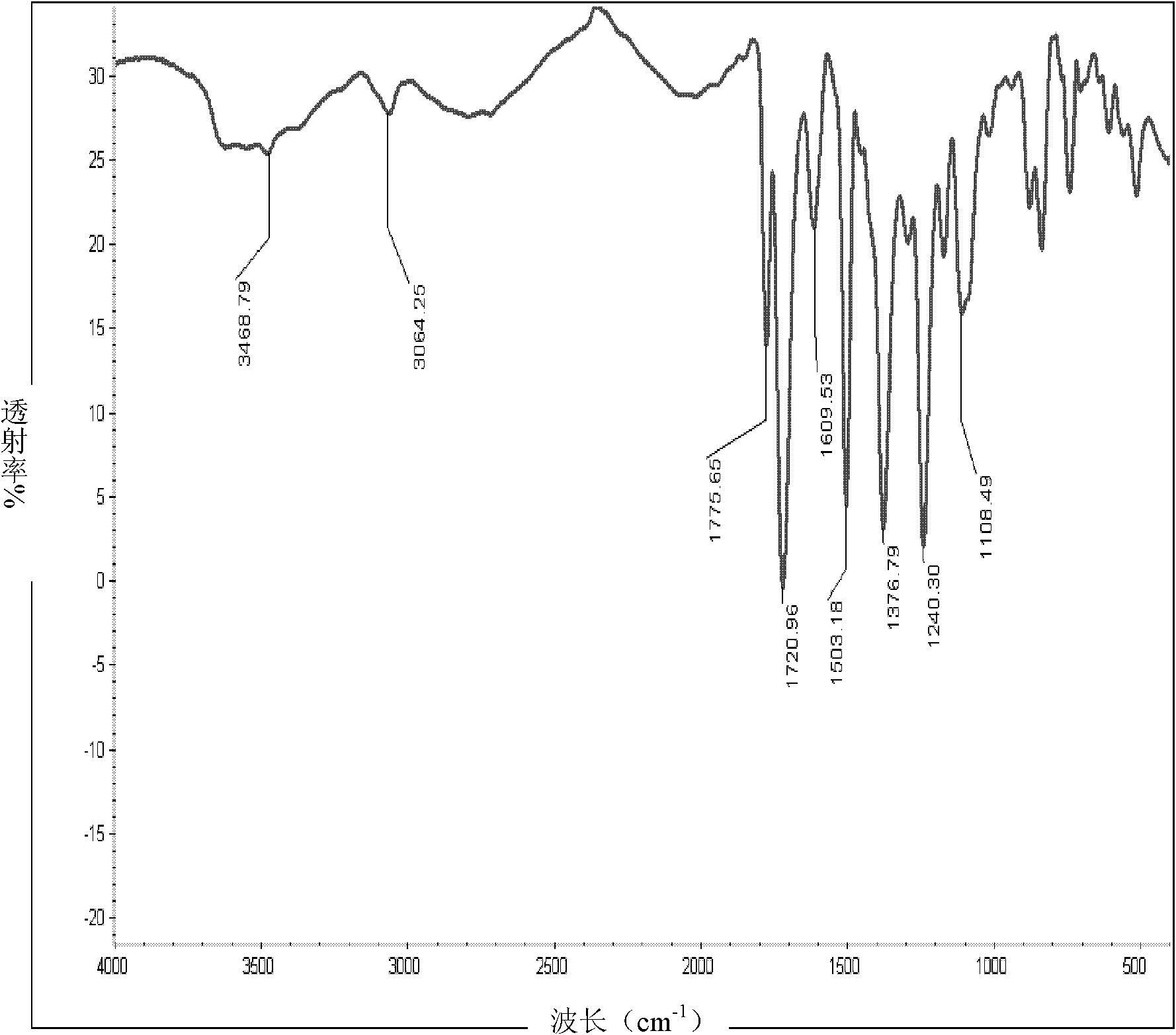

[0050] 1.52 grams (0.01 moles) of 3,5-diaminobenzoic acid, 29.20 grams (0.1 moles) of 1,3-bis(3-aminophenoxy)benzene and 350 milliliters of N,N-dimethylacetamide were strongly polarized Put the neutral aprotic organic solvent into the reaction kettle, at room temperature, after stirring and dissolving completely, add 34.10 grams (0.11 moles) of aromatic dibasic acid anhydride powder of 3,3',4,4'-tetracarboxylic diphenyl ether dianhydride After stirring and reacting at room temperature for 1.5-2 hours, a homogeneous transparent viscous resin solution was obtained; 35 ml of xylene azeotropic dehydrating agent was added, and after azeotropic reflux and water separation for 4-5 hours, 180 ml of azeotropic dehydrating agent and some strong polar aprotic organic solvents to obtain a reactive polyimide resin solution with a solid content of 20%-25%, which is denoted as OPI240; a small amount of resin solution is taken out, the solvent is removed, and dried to obtain a dry Reactive po...

Embodiment 3

[0057] 15.20 grams (0.1 moles) of 3,5-diaminobenzoic acid, 29.20 grams (0.1 moles) of 1,3-bis(3-aminophenoxy)benzene, 50 milliliters of N-methyl-2-pyrrolidone and 450 milliliters N,N-Dimethylacetamide strong polar aprotic organic solvent is put into the reaction kettle, after stirring and dissolving completely at room temperature, add 31.00 g (0.1 mole) of 3,3',4,4'-tetracarboxylic dicarboxylic acid Phenyl ether dianhydride and 52.05 grams (0.1 mole) of 2,2-bis[4-(3,4-dicarboxyphenoxy) phenyl] propane dianhydride aromatic dibasic anhydride powder, stirring reaction at room temperature for 1.5- After 2 hours, obtain a homogeneous transparent viscous resin solution; add 25 milliliters of xylene and 50 milliliters of toluene azeotropic dehydrating agent, after azeotropic reflux and water separation reaction for 4-5 hours, separate 125 milliliters of azeotropic dehydrating agent and Part of the strong polar aprotic organic solvent to obtain a reactive polyimide resin solution with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com