High-temperature resisting adhesive and preparation method thereof

A high-temperature-resistant adhesive and formulation technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve problems such as unfavorable marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

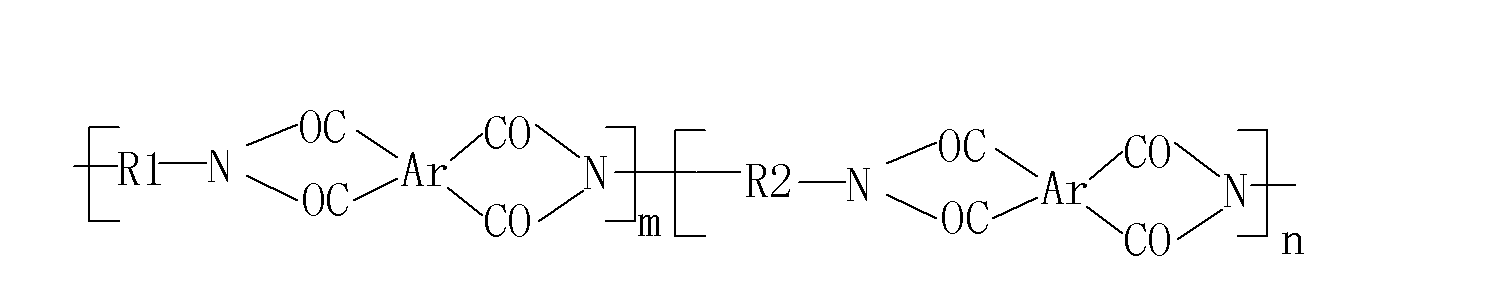

Method used

Image

Examples

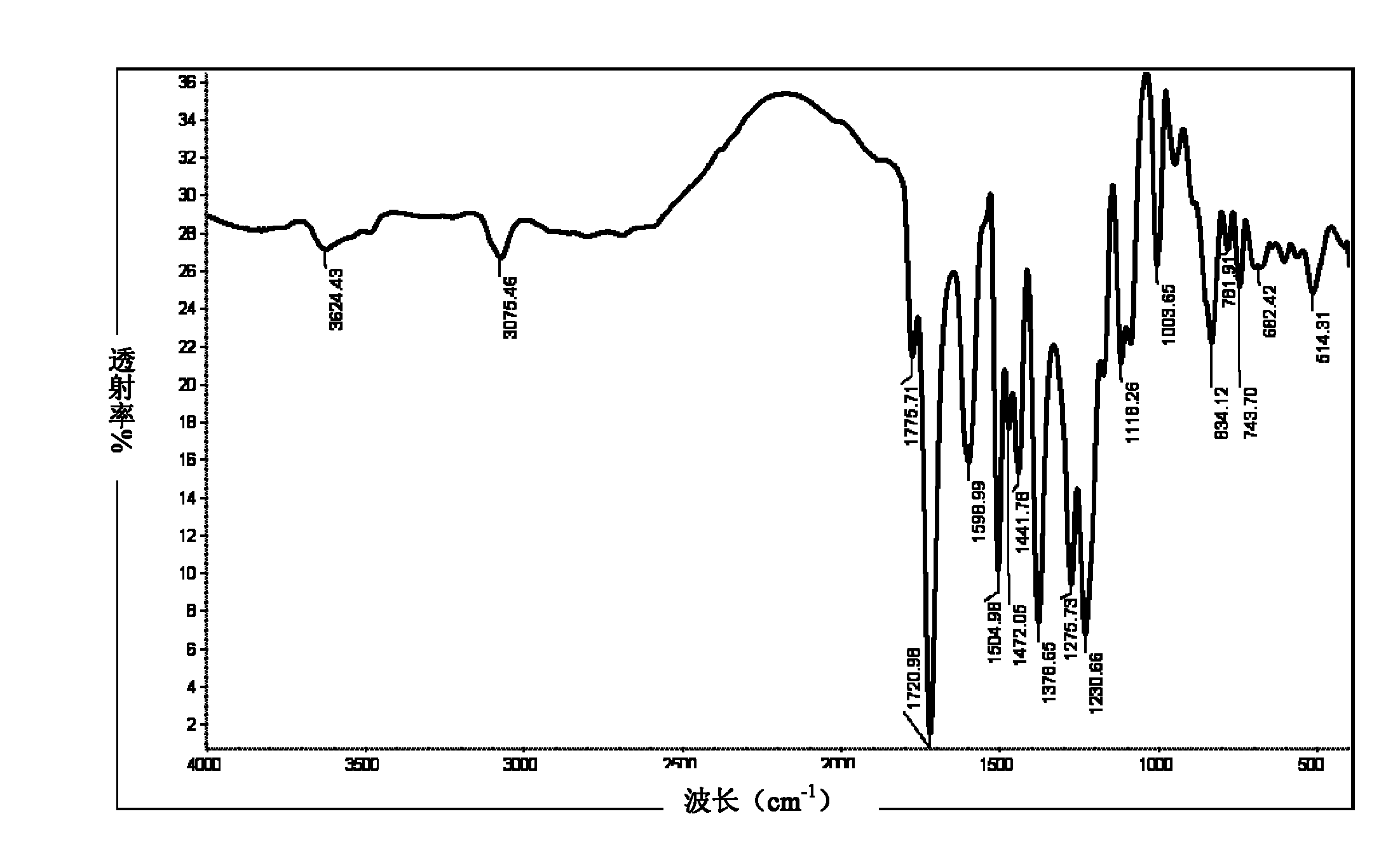

Embodiment 1

[0063]33.60 grams (0.1 moles) of 3,5-bis(4-aminophenoxy)benzoic acid, 1.08 grams (0.01 moles) of 1,3-diaminobenzene and 560 milliliters of N-methyl-2-pyrrolidone strongly polar Put the aprotic organic solvent into the reactor, at room temperature, after stirring and dissolving completely, add 34.10 grams (0.11 moles) of 3,3',4,4'-tetracarboxylic diphenyl ether dianhydride aromatic dibasic acid anhydride powder, After stirring and reacting at room temperature for 2-3 hours, a homogeneous transparent viscous resin solution was obtained; 56.10 grams (0.55 moles) of acetic anhydride dehydrating agent and 5.56 grams (0.055 moles) of triethylamine catalyst were added, at 90°C-110°C After 4-5 hours of high-speed stirring reaction within the temperature range, 5600 ml of ethanol precipitant was added to precipitate solid powder, filtered, washed with acetone 2-3 times, and vacuum-dried within the temperature range of 120°C-150°C to obtain 63.52 Gram (theoretical output: 64.82 grams) c...

Embodiment 2

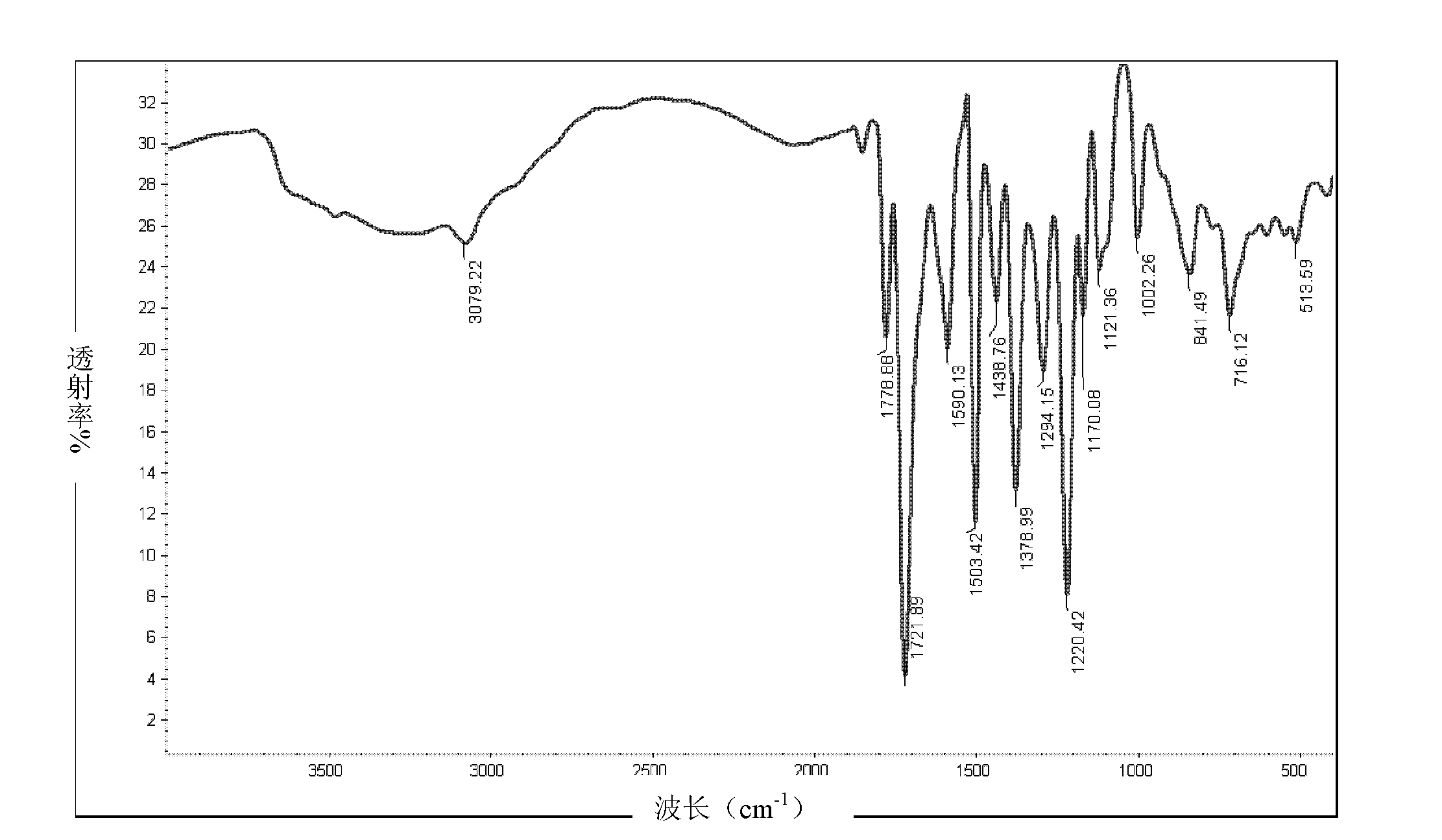

[0070] 3.36 grams (0.01 moles) of 3,5-bis(4-aminophenoxy)benzoic acid, 292 grams (0.1 moles) of 1,3-bis(3-aminophenoxy)benzene, 300 milliliters of N,N- Dimethylformamide and 310 milliliters of N, N-dimethylacetamide strong polar aprotic organic solvent are put into reaction kettle, at room temperature, after stirring and dissolving completely, add 35.42 grams (0.11 moles) 3, 3 ', 4, the aromatic dibasic acid anhydride powder of 4'-tetracarboxylic benzophenone dianhydride, after stirring and reacting at room temperature for 2-3 hours, obtain a homogeneous transparent viscous resin solution; add 112.2 grams (11 moles) of ethyl alcohol Acid anhydride dehydrating agent, 5.56 grams (0.055 moles) of triethylamine and 4.34 grams (0.055 moles) of pyridine catalyst, after 4-5 hours of high-speed stirring reaction in the temperature range of 90°C-110°C, add 2050 milliliters of ethanol and 1000 milliliters of methanol Precipitating agent, precipitated solid powder, filtered, washed 2-3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com