Oil displacement method for tertiary oil recovery

An oil displacement method and oil displacement technology, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve the problems of alkaline corrosion, poor oil displacement efficiency, and high use concentration in ASP flooding, and achieve a reduction in interface Strong tensile capacity, excellent performance, high salinity resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

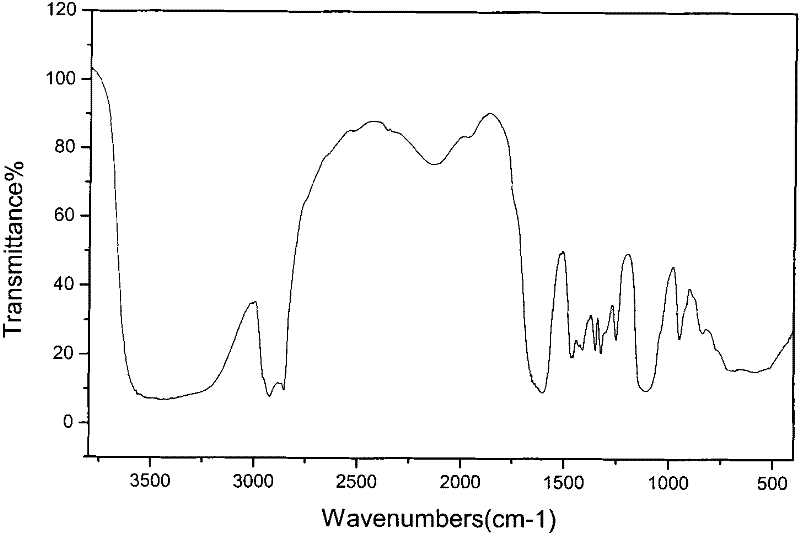

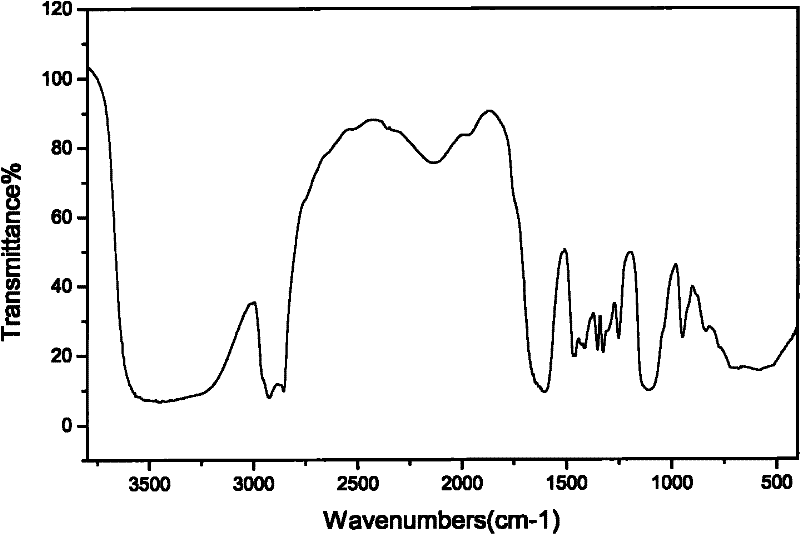

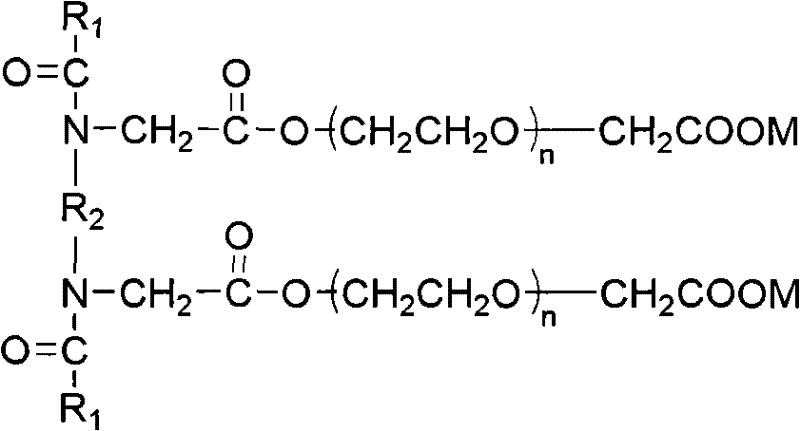

Image

Examples

Embodiment 1

[0036] (a) Synthesis of two lauryl (lauroyl) ethylenediamine

[0037] 300 grams (1.5 moles) of lauric acid, 267.8 grams (2.25 moles) of thionyl chloride and 4.5 grams of DMF were added to a 2000-milliliter four-necked flask equipped with a sealed mechanical stirrer, a thermometer, a condenser tube, etc., and reacted at 90 ° C for 3 After one hour, excess thionyl chloride was distilled off under reduced pressure to obtain lauroyl chloride. When the temperature drops to 60°C, add 150 grams of dry toluene, and after stirring evenly, slowly add 30.0 grams (0.5 moles) of anhydrous ethylenediamine, 99.0 grams (1.25 moles) of anhydrous pyridine and 150 grams of dry toluene The mixed solution of gram composition, control temperature is less than 60 ℃, dropwise and be warmed up to 85 ℃ and react for 2 hours. After cooling and filtering, the crude product was recrystallized from ethanol and dried in vacuo to obtain a white powdery solid with a molar yield of 97.1%.

[0038] (b) Synthe...

Embodiment 2

[0047] (a) Synthesis of double lauryl hexamethylene diamine

[0048] Same as [Example 1] (a), except that 58.0 grams (0.5 moles) of anhydrous hexamethylenediamine is used to replace 30.0 grams (0.5 moles) of anhydrous ethylenediamine, and the rest are the same. After vacuum drying, a white powdery solid is obtained. The molar yield is 95.6%.

[0049] (b) Synthesis of N, N-dilauroyl hexamethylene diamine diacetic acid

[0050] 225.6 grams (0.47 moles) of dilauroyl hexamethylenediamine, 450 grams of tetrahydrofuran, 105.3 grams (1.88 moles) of potassium hydroxide and 4.5 grams of tetrabutylammonium bromide are added with mechanical stirring and thermometer And in the 2000 milliliter three-neck flask of reflux condenser, be heated to reflux alkalinization reaction 3 hours. After cooling slightly, add a total of 164.3 grams (1.41 moles) of sodium chloroacetate solid five times, and keep the reflux reaction for 9 hours. Cool, neutralize with hydrochloric acid until the reaction ...

Embodiment 3

[0058] (a) Synthesis of two ten (decyl) acyl butanediamine

[0059] With [Example 1] (a), the difference replaces 300.0 grams (1.5 moles) of lauric acid with 261.0 grams (1.5 moles) of capric acid, and replaces 30.0 grams (0.5 moles) of anhydrous butanediamine with 44.0 grams (0.5 moles). mol) anhydrous ethylenediamine, and the rest are the same, and after vacuum drying, a white powdery solid is obtained, and the molar yield is 96.7%.

[0060] (b) N, the synthesis of N-didecanoyl butanediamine diacetic acid

[0061] 186.1 grams (0.47 moles) of bis-decanoyl butanediamine synthesized in step (a), 400 grams of tetrahydrofuran (THF), 112.8 grams (2.82 moles) of sodium hydroxide and 7.5 grams of tetrabutylammonium bromide are added and equipped with a mechanical stirrer and a thermometer And in the 2000 milliliter three-neck flask of reflux condenser, be heated to reflux alkalinization reaction 3 hours. After cooling slightly, add a total of 219.0 g (1.88 moles) of sodium chloroa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com