Method for plasma spraying of Ca-P bioactive coating on surface of magnesium alloy

A surface plasma and bioactive technology, applied in the preparation process of ion-sprayed calcium-phosphorus bioactive coatings, can solve the problems of low bioactivity of biomaterials, and achieve the effect of being suitable for automatic production, simple operation, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Material preparation and cleaning. The square flake magnesium alloy AZ31B was used as the substrate, and the substrate was ultrasonically cleaned with acetone and deionized water for 10 min, wiped with filter paper, and air-dried for later use. In ultrasonic cleaning, the ultrasonic power is 40KW and the frequency is 150khz.

[0022] Step 2: Surface sandblasting. The surface of the magnesium alloy was roughened by sandblasting with 24 mesh corundum sand, the sandblasting time was 10s, the sandblasting pressure was 0.25MPa, and the roughness Ra was maintained at 8-15μm.

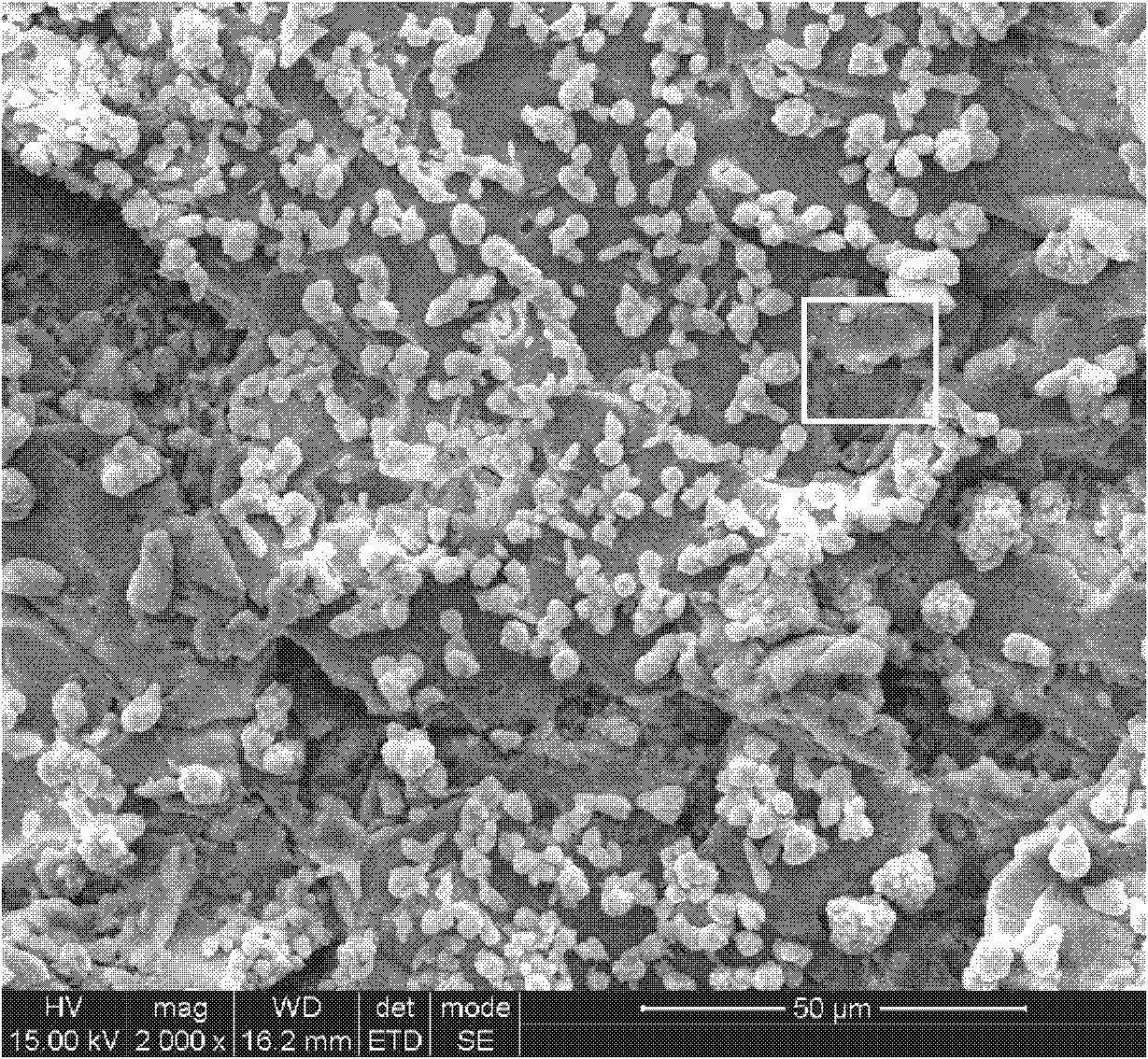

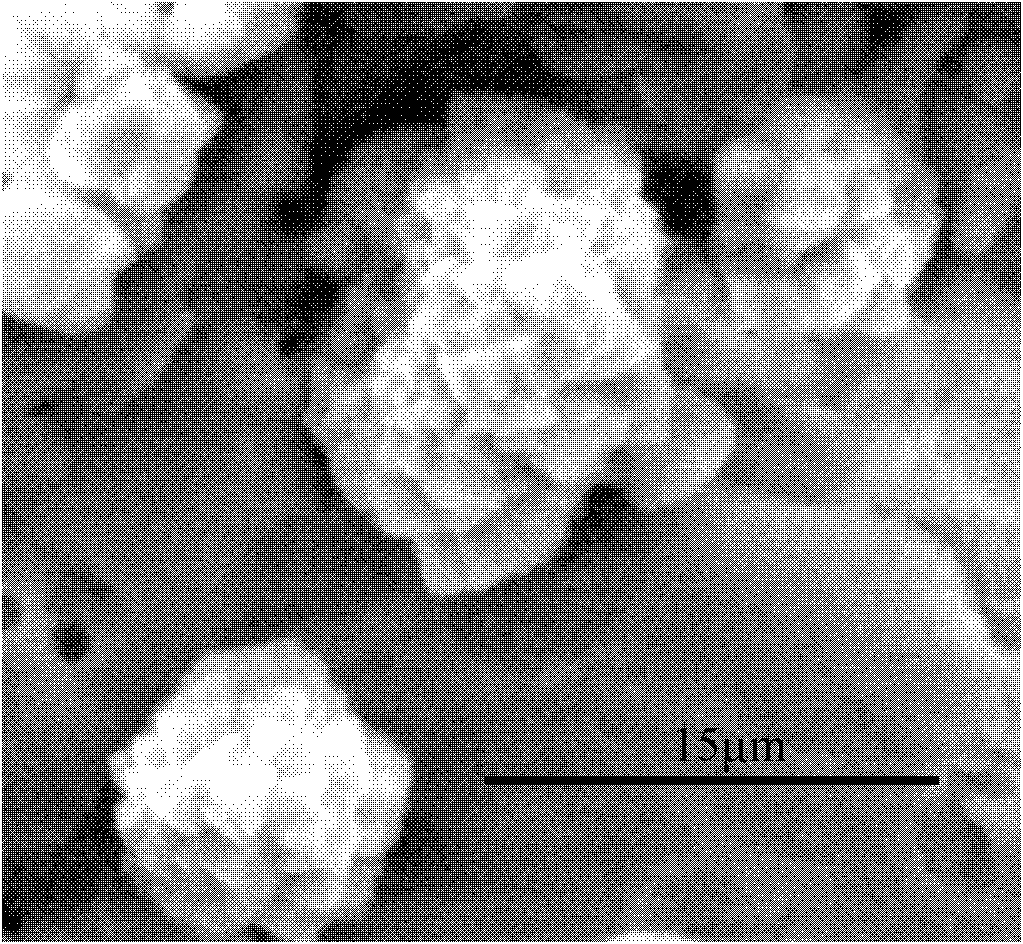

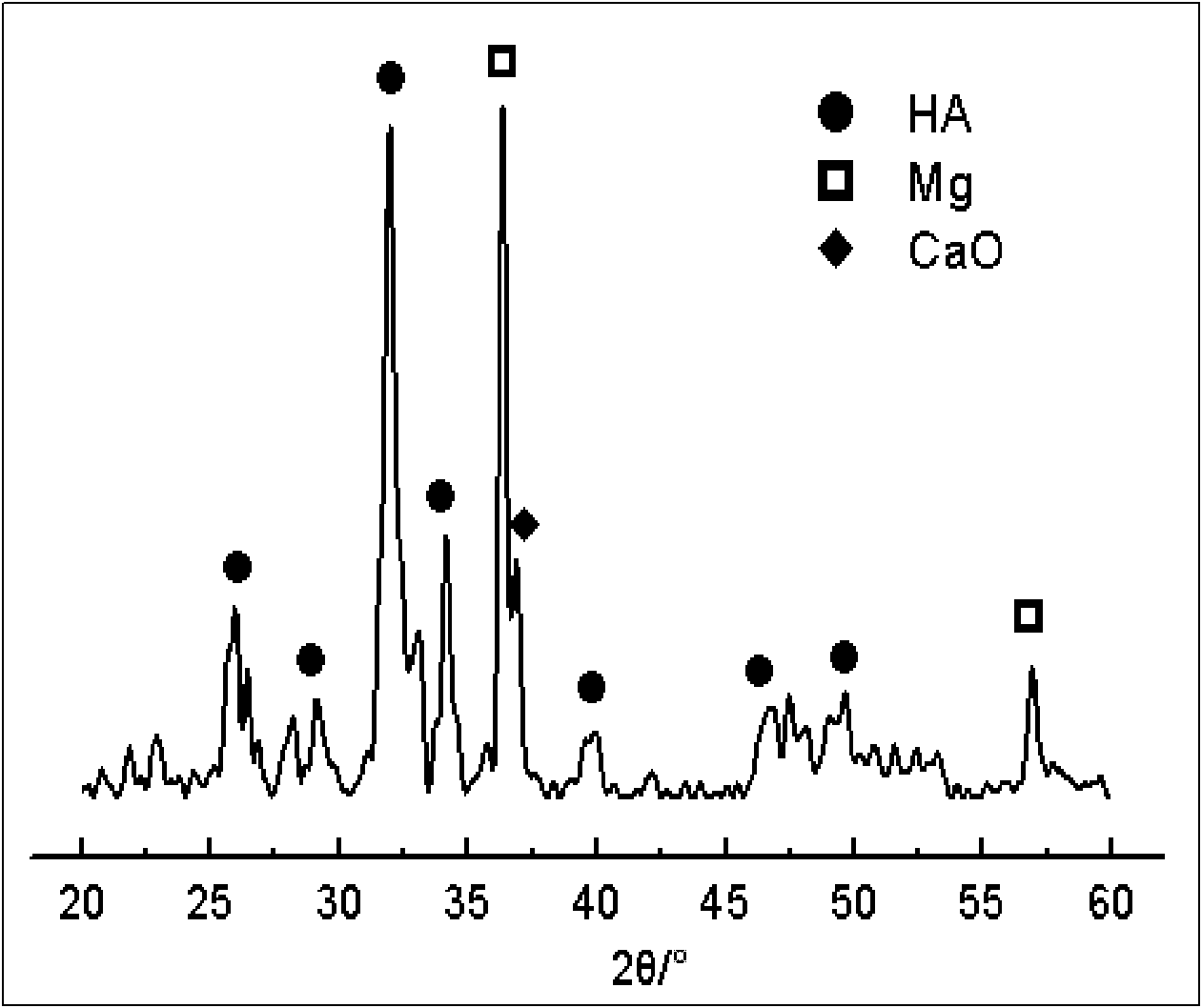

[0023] Step three: plasma spraying. The Ca-P bioactive coating was prepared on the surface of the magnesium alloy substrate after sandblasting by using Praxair 7700 atmospheric plasma spraying equipment. Before spraying, the substrate was preheated at 150°C with a plasma jet flame. The spraying process is realized by controlling the following parameters: main gas (Ar) 45L / min, auxiliary gas ...

Embodiment 2

[0027] Step 1: Material preparation and cleaning. The square flake magnesium alloy AZ31B was used as the substrate, and the substrate was ultrasonically cleaned with acetone and deionized water for 10 min, wiped with filter paper, and air-dried for later use. In ultrasonic cleaning, the ultrasonic power is 40KW and the frequency is 150khz.

[0028] Step 2: Surface blasting treatment: use 24-mesh corundum sand to roughen the surface of the magnesium alloy. The blasting time is 8s, the blasting pressure is 0.20MPa, and the roughness Ra is maintained at 8-12μm.

[0029] Step 3: Plasma spraying: A Ca-P bioactive coating was prepared on the surface of the sandblasted magnesium alloy substrate using Praxair 7700 atmospheric plasma spraying equipment, and the substrate was preheated at 170°C with a plasma jet flame before spraying. The spraying process is realized by controlling the following parameters: main gas (Ar) 47L / min, auxiliary gas (He) 13L / min, spraying power 24.5kw, spray...

Embodiment 3

[0032] Step 1: Material preparation and cleaning. The square flake magnesium alloy AZ31B was used as the substrate, and the substrate was ultrasonically cleaned with acetone and deionized water for 10 min, wiped with filter paper, and air-dried for later use. In ultrasonic cleaning, the ultrasonic power is 40KW and the frequency is 150khz.

[0033] Step 2: Surface blasting treatment: use 24-mesh corundum sand to roughen the surface of the magnesium alloy by blasting for 10s, blasting pressure at 0.25MPa, and keep the roughness Ra at 8-15 μm.

[0034]Step 3: Plasma spraying: The Ca-P bioactive coating was prepared on the surface of the magnesium alloy substrate after sandblasting using Praxair 7700 atmospheric plasma spraying equipment, and the substrate was preheated at 180°C with a plasma jet flame before spraying. The spraying process is realized by controlling the following parameters: main gas (Ar) 48L / min, auxiliary gas (He) 15L / min, spraying power 25kw, spray gun moving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com