Process for multistep directional o-cresol conversion with biological method

A biotransformation and directional transformation technology, applied in the field of bioengineering, can solve problems such as difficult to control the transformation process at all levels, difficult to achieve controllable and directional transformation of toluene and methylbenzene, and achieve directional controllable and directional transformation of the production process. The effect of low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

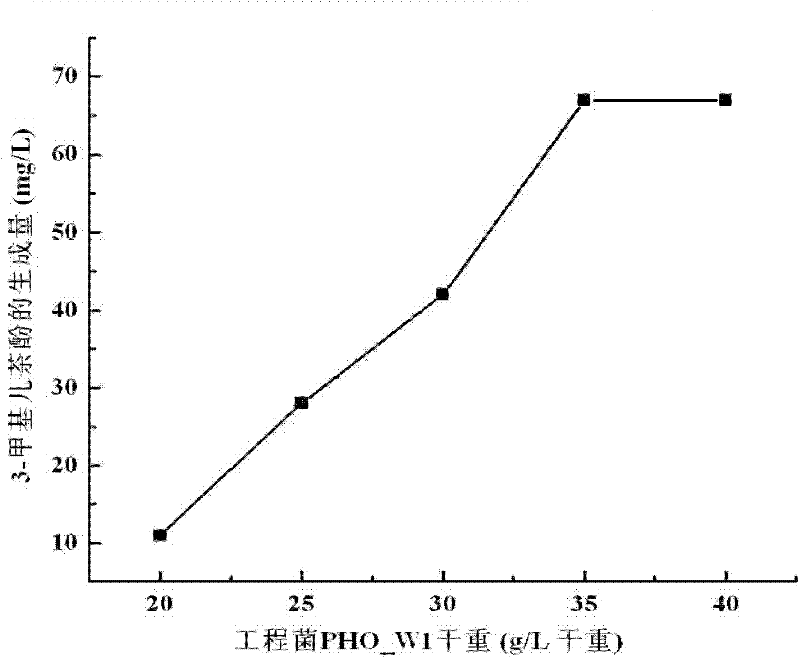

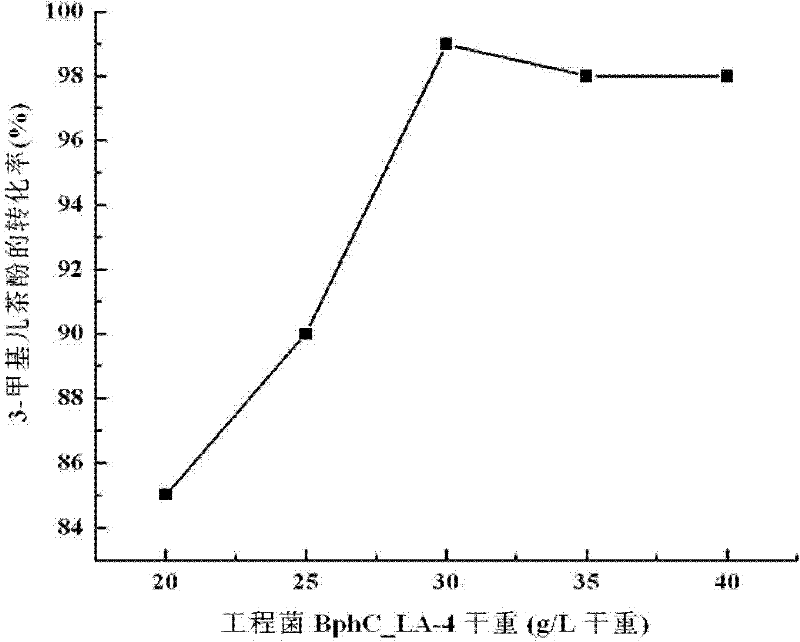

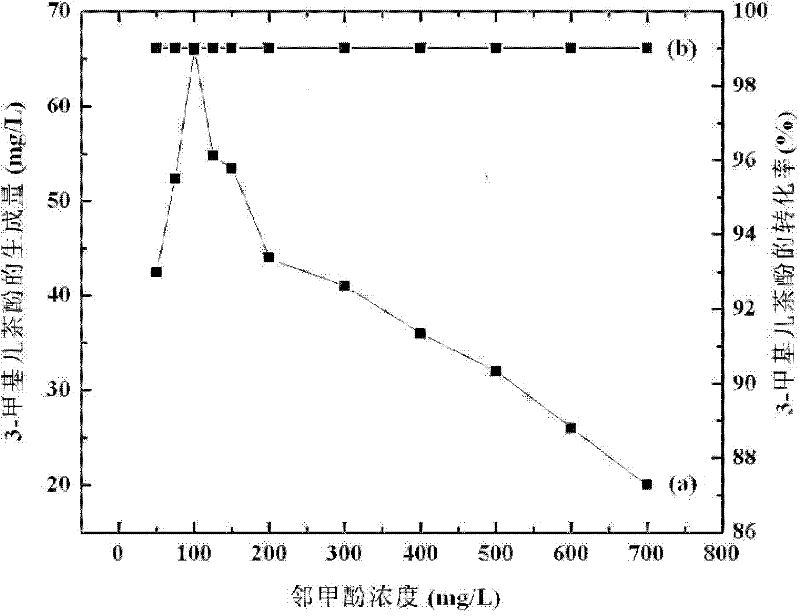

[0028] Embodiment 1, phenol hydroxylase genetically engineered bacteria PH_ IND and biphenyl exodiol dioxygenase genetically engineered bacteria BphC_LA-4 for multi-stage directional conversion of o-cresol, and the effects of some parameters on the production and conversion rate of 3-methylcatechol were investigated.

[0029] Engineering bacteria PH_ IND The medium used for expanding the culture of engineering bacteria BphC_LA-4 is LB medium, the formula is: 10g / L NaCl, 10g / L peptone, 5g / L yeast extract, adjust the pH to 7.0-7.2, and sterilize at 121°C After 20 minutes, add kanamycin at a final concentration of 10-20 mmol / L as an antibiotic after the culture medium is cooled. The formula of solid plate medium is 15-20g / L agar added on the basis of LB medium. The expanded culture of genetically engineered bacteria and the biotransformation o-cresol reaction steps and parameters are as follows:

[0030] 1. The engineering bacteria PH_ IND Inoculate the solid plate LB medium ...

Embodiment 2

[0045] Embodiment 2, phenol hydroxylase genetically engineered bacteria PH_ IND Multi-stage directed transformation of o-cresol with BphC_LA-4 genetically engineered bacterium BphC_LA-4.

[0046] LB substratum formula and the expanded culture of genetically engineered bacterium and biotransformation o-cresol reaction step 1~5 are with embodiment 1, make the engineering bacterium PH that step 3 makes by controlling the collected thalline quality. IND The dry weight of whole cells is 20g / L, and the dry weight of whole cells of engineering bacteria BphC_LA-4 is 25g / L.

[0047] The first level biotransformation reaction: in the Erlenmeyer flask of 50mL, add the engineering bacteria PH_ that 20mL step 3 makes IND Whole cells, 15 μL of o-cresol solution prepared in step 4, 600 μL of glucose stock solution prepared in step 5, so that the concentration of o-cresol in the reaction solution is 50 mg / L, and the concentration of glucose is 30 mmol / L. At 40 ° C, shake The bed speed is 18...

Embodiment 3

[0050] Embodiment 3, phenol hydroxylase genetically engineered bacteria PH_ IND Multi-stage directed transformation of o-cresol with BphC_LA-4 genetically engineered bacterium BphC_LA-4.

[0051] LB substratum formula and the expanded culture of genetically engineered bacteria and biotransformation o-cresol reaction steps 1~5 are with embodiment 1, wherein the engineering bacteria PH that step 3 makes IND The dry weight of whole cells is 25g / L, and the dry weight of whole cells of engineering bacteria BphC_LA-4 is 20g / L.

[0052] The first level biotransformation reaction: in the Erlenmeyer flask of 50mL, add the engineering bacteria PH_ that 20mL step 3 makes IND Whole cells, 40 μL of o-cresol solution prepared in step 4, 100 μL of glucose stock solution prepared in step 5, so that the concentration of o-cresol in the reaction solution is 200 mg / L, and the concentration of glucose is 5 mmol / L. At 35 ° C, shake Bed speed 200r / min, shaking reaction 240min;

[0053]The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com