Method for preparing freeze-dried human blood coagulation factor VIII

A human coagulation factor and freeze-drying technology is applied in the field of preparation of freeze-dried human coagulation factor VIII, which can solve the problems of low product yield and success rate, and achieve the effects of avoiding Al3+ residue, improving activity recovery rate and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

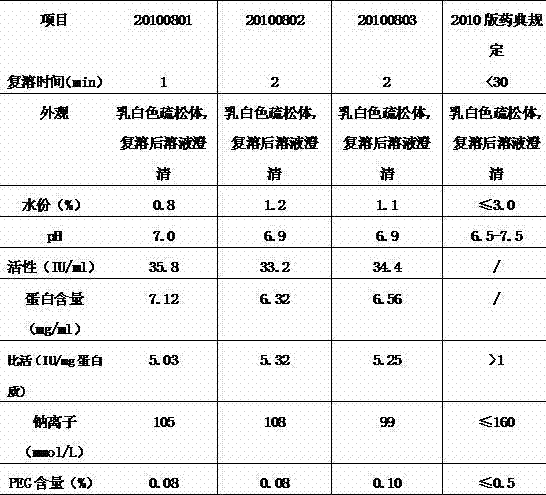

Embodiment 1

[0035] A preparation method of freeze-dried human blood coagulation factor VIII, comprising the following process: using water for injection containing 3-10 IU / ml of heparin as heparin sodium solution to dissolve cryoprecipitate, taking the supernatant after PEG precipitation, and centrifugally filtering, 24-26 ℃ S / D inactivation, DEAE Sepharose Fast Flow chromatography column equilibration, adsorption, washing, elution, molecular membrane ultrafiltration, preparation, sterilization and packaging, freeze-drying, capping, 99.5-100.5 ℃ dry heat inactivation; The specific process is as follows:

[0036] 1. Take plasma cryoprecipitate that meets the requirements of the pharmacopoeia: melt at room temperature for 1-2 hours, process into small pieces of 1.5-2.5cm, and wet crush;

[0037] 2. Cryoprecipitate dissolution: place the cryoprecipitate in 5-6 times the volume of heparin sodium solution, stir for 1 hour, then adjust the pH to 6.5-7.5 with 1mol / L HCl, continue stirring for 20...

Embodiment 2

[0068] The basic requirements are the same as those in Embodiment 1.

[0069] A preparation method of freeze-dried human blood coagulation factor VIII, comprising the following process: using water for injection containing 3-10 IU / ml of heparin as heparin sodium solution to dissolve cryoprecipitate, taking the supernatant after PEG precipitation, and centrifugally filtering, 24-26 ℃ S / D inactivation, DEAE Sepharose Fast Flow chromatography column equilibration, adsorption, washing, elution, molecular membrane ultrafiltration, preparation, sterilization and packaging, freeze-drying, capping, 99.5-100.5 ℃ dry heat inactivation; The specific process is as follows:

[0070] 1. Take plasma cryoprecipitate that meets the requirements of the pharmacopoeia: melt at room temperature for 1-2 hours, process into small pieces of 1.5-2.5cm, and wet crush;

[0071] 2. Cryoprecipitate dissolution: place the cryoprecipitate in 5-6 times the volume of heparin sodium solution, stir for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com