Preparation method for separating and purifying single heavy rare earth by using full-extraction process

A heavy rare earth and extraction technology, applied in the direction of improving process efficiency, can solve the problems of small organic operation capacity, difficult production control of tank body, small separation coefficient, etc., and achieves low consumption of acid and alkali raw materials and low comprehensive production cost. , Balance the effect of low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

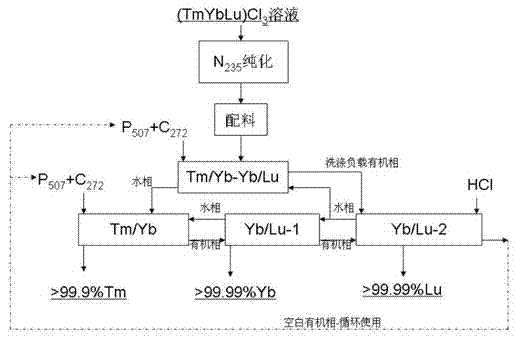

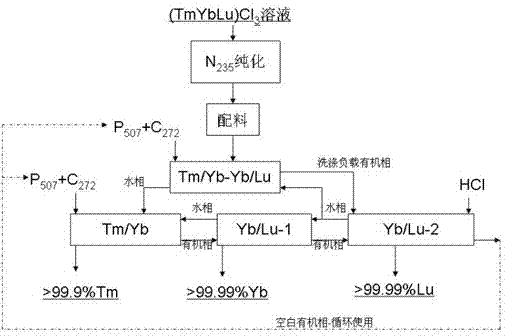

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail: as figure 1 : A preparation method for separating and purifying a single heavy rare earth by a total extraction process, characterized in that: the thulium, ytterbium and lutetium concentrates are used as raw materials, and firstly treated with N 235 Purify non-rare earth impurities, and then pass P 507 +C 272 The double extractant system is used for total extraction, separation and purification to obtain Tm 2 o 3 , Yb 2 o 3 、Lu 2 o 3 High-purity single rare earth products, including the following process steps:

[0014] 1. Group fuzzy block (thulium ytterbium / ytterbium lutetium separation): 70 stages in total, 4th stage for saponification and rare earth soap, 38th stage feed, 70th stage for washing liquid; 5th stage for qualified thulium ytterbium liquid, 70th stage Qualified ytterbium-lutetium liquid produced from organic grade;

[0015] Input paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com