Preparation method of surface hard protective film for guide wire/tunnel needle used in peritoneal dialysis catheter insertion

A technology of peritoneal dialysis and protective film, which is applied in the field of film preparation to achieve the effects of not falling off easily, improving high temperature resistance and high pressure sterilization, and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

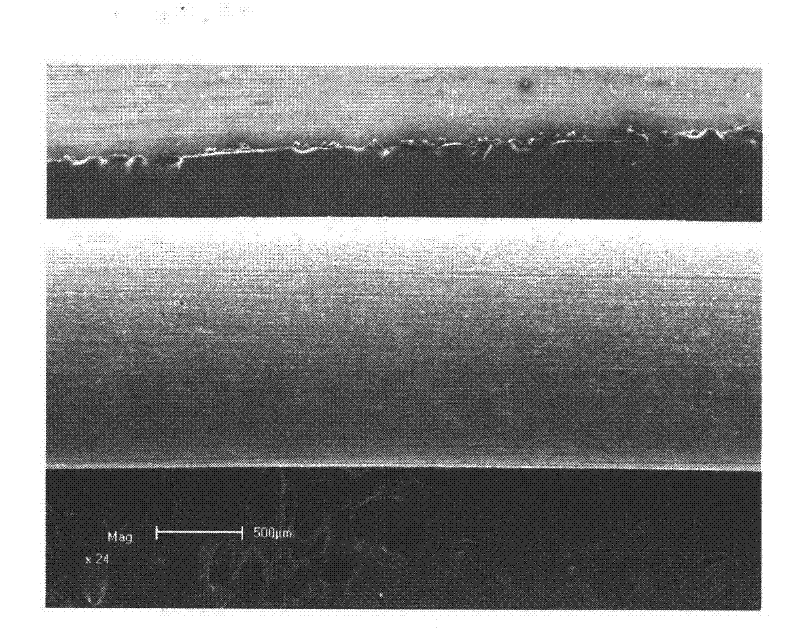

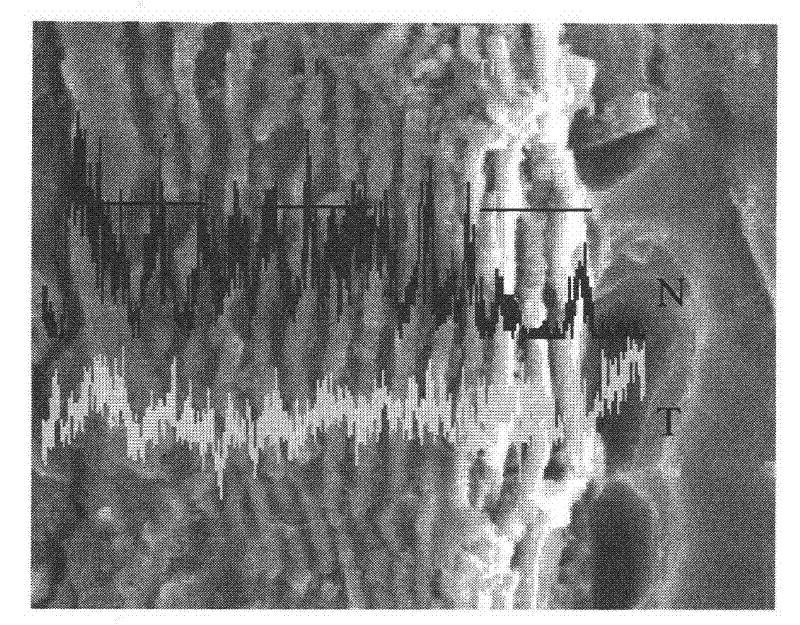

[0025] Example 1: Depositing a Ti+TiN multilayer film on the surface of the guide wire using a magnetron sputtering device

[0026] A planar fixed target magnetron sputtering system is used. The vacuum chamber of the system is a flat cylindrical shape, and the bottom surface of the cylinder is the vacuum chamber door. The target material is pure titanium (99.99%), followed by a permanent magnet and a water cooling system, placed on the side wall (cylindrical surface) of the vacuum chamber. A copper wire with a diameter of 1.2mm and a length of 50cm was selected, cleaned by dilute phosphoric acid, ultrasonically cleaned by anhydrous ethanol, dried, and then suspended in the vacuum chamber of the magnetron sputtering device facing the rectangular Ti target. The vacuum chamber is evacuated to 2×10 -3 After Pa, argon gas was introduced and the gas pressure in the vacuum chamber was maintained at 2.0 Pa. The negative pole of the power supply is connected to the target, the posit...

Embodiment 2

[0029] Example 2: Using an arc ion plating device to deposit a Ti+TiN gradient film on the surface of the guide wire

[0030] The domestic MIP-8-800 arc ion plating device is adopted. A titanium wire with a diameter of 1.5 mm and a length of 45 cm was selected, cleaned with dilute phosphoric acid, ultrasonically cleaned with anhydrous ethanol, dried, and then suspended in the vacuum chamber of the arc ion plating device facing the Ti target. In the device, three Ti targets are arranged up and down facing the titanium wire. Turn on the sample heating system and set the temperature to 300 °C. Evacuate the vacuum chamber to 3 x 10 -3 After Pa, argon gas was introduced and the gas pressure in the vacuum chamber was maintained at 2.0 Pa. Start the hanger and make the Ti wire rotate. Apply a negative bias voltage -800V (adjust the duty cycle to 5%) between the target and the metal Ti wire, and perform glow cleaning on the Ti wire for 3 minutes; after that, adjust the flow of arg...

Embodiment 3

[0033] Example 3: Depositing a TiN film on the surface of the tunnel needle using an arc ion plating device

[0034] The domestic MIP-8-800 arc ion plating device is adopted. Choose a 316L stainless steel tunnel needle with a diameter of Φ10×100mm, wash it with dilute phosphoric acid, ultrasonically clean it with absolute ethanol, and dry it, and then hang it facing the Ti target in the vacuum chamber of the arc ion plating device. Select two Ti targets arranged up and down in the device to work. The vacuum chamber is evacuated to 3×10 -3 After Pa, argon gas was introduced and the gas pressure in the vacuum chamber was maintained at 2.0 Pa. Start the turntable to make the suspended tunnel needle rotate by itself. A negative bias of -800V was applied between the stainless steel tunnel needle and the target (the duty ratio was adjusted to 5%), and the workpiece was glow-cleaned for 3 minutes; after that, the flow of argon gas was adjusted to adjust the gas pressure of the vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com