Olefin polymerization reaction apparatus and method

A technology of olefin polymerization and reaction equipment, which is applied in the field of petrochemical industry, can solve the problems of gas distributor blockage, reduce the number of shutdowns, prolong the production cycle, etc., and achieve the effects of avoiding temperature gradient, improving stability and prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with embodiment, further illustrate the present invention.

[0063] The components in the embodiment are as follows: the catalyst is titanium chloride supported on magnesium dichloride, the polymerizable monomer is ethylene, the comonomer is butene, and the chain transfer agent is hydrogen. Non-reactants include nitrogen, propane, n-butane, and isopentane.

[0064] The specific process of the embodiment is as follows:

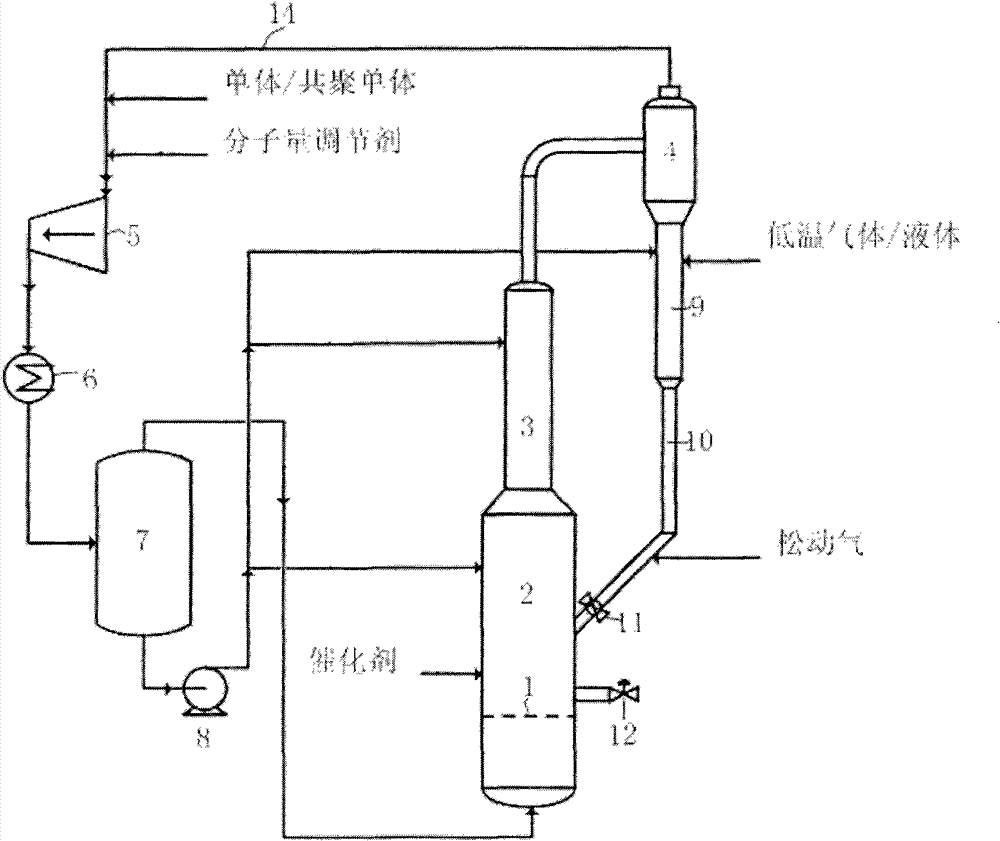

[0065] Such as figure 1 As shown, the catalyst enters the reaction system from the first reactor 2, that is, the lower part of the bubbling fluidized bed, through a pipeline. Freshly added monomers and comonomers enter the main circulation gas pipeline 14 through pipelines respectively. The circulating gas flows into the compressor 5 and then flows to the circulating gas cooler 6 to be condensed into a gas-liquid mixture. After the gas-liquid mixture passes through the liquid collection tank 7, the separation of gas and liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com